By Peter Barry, CENG, MSC, M.AIRAH

ABSTRACT

In the future, many Australian HVAC systems may be required to deal with harsher environmental conditions due to more extreme climatic conditions and a push to increase population centres in more northern and central regions of the country.

BHP has for many years maintained a large operation in the Pilbara region of Western Australia to extract, process and transport iron ore for seaborne transportation to its customers; this includes numerous office and other air conditioned buildings to support these operations.

The extreme nature of the ambient environment due to dust, heat and high humidity have caused issues including problems with equipment failure, mould, operator discomfort, condensation, high operating costs and damage to the building fabric and furniture.

In many cases these problems have arisen due to poor understanding of how to deal with the difficult ambient conditions by system designers and architects, or failure to maintain adequate standards during construction.

The many lessons learned in these facilities provide an insight into how HVAC designs in general may be developed to meet future requirements in Australia’s potentially more challenging environmental future.

INTRODUCTION

For much of the population of Australia, including many consulting engineers based in the major cities, the wide brown land of drought and flooding rains described by Dorothea Mackellar in her 1908 published poem is a distant place that is not often considered during their daily lives.

However, the changing climate and the increase of populations into less settled areas due to expansion on the fringes of existing towns or into remote areas for economic benefit will mean the harsher conditions experienced will need to be considered in the development of many future HVAC systems.

The Australian government/CSIRO website “Climate Change in Australia” [4] states that in all regions of Australia, there is high or very high confidence that average temperatures and the occurrence of extreme temperatures will increase in the remaining decades of this century. Additionally, there is high confidence that many areas will see a reduction in average rainfall but with an increase in extreme rainfall events. These warm, dry conditions interspersed with moments of wild weather are already prevalent in the Pilbara, and require significant modification to the design of HVAC when compared to normal practice in most major Australian cities.

Unfortunately, the lessons of the past frequently do not get learned or passed on. Many of the historic issues that have been experienced with HVAC systems in the region can be traced to the apparent inability within the industry to understand how the harsh climate and local conditions can make designs that would work in more temperate parts of the country fail. There is also a real concern that increasing complexity combined with a reduction in robustness in the design of systems and equipment in a push for increased efficiencies in energy and cost will make the Pilbara an even more difficult place to be comfortable.

LIFE, BUT PROBABLY NOT AS YOU KNOW IT …

To appreciate the issues of the future, an appreciation of the issues of the present is essential.

Fig. 1 The Pilbara Region of Western Australia.

According to the government of Western Australia’s Living in Western Australia website (https://migration.wa.gov.au/living-in-western-australia), the Pilbara is a region of Western Australia covering 507,896km², accounting for 30% of the resources industry in Australia and with a population of just 66,000. Its largest town, Karratha is 1,557km north of the WA state capital, Perth, see figure 1.

The Pilbara climate is predominantly semi-arid but near the coast can be very humid. Temperatures can be extreme for six months of the year: the town of Marble Bar recently held the world record for the number of consecutive days in which the maximum temperature equalled or exceeded 38°C (160 days). Although it is often dry, wind and rainfall events can be extreme, and the Pilbara coast experiences more cyclones that any other part of Australia: the town of Port Hedland on average is affected by a cyclone once every two years.

So what does a list of the challenges facing designers of HVAC systems and equipment in the northwest corner of the second driest continent look like? Such a list would have to include, in no particular order of importance:

- High temperatures

- High Humidity in coastal regions

- Dust

- Extreme weather events

- Remoteness.

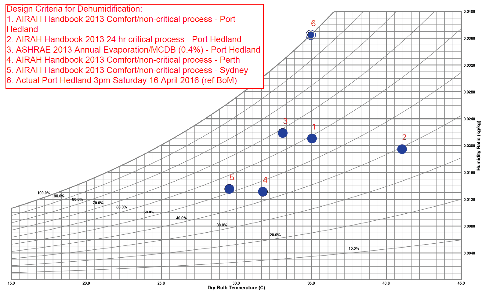

Figure 2 – Ambient design conditions for Port Hedland, Perth and Sydney

AMBIENT DESIGN CONDITIONS FOR HVAC DESIGN

Heat and Humidity

As an illustration of the more demanding conditions that need to be allowed for when designing HVAC for the Pilbara, Figure 2 plots recommended ambient summer design conditions for Port Hedland as well as for Perth and Sydney as a comparison.

Points 1 to 3 on the psychrometric chart are various design conditions as recommended by AIRAH [2] and ASHRAE [3], which indicate a much greater degree of cooling and dehumidification will be required to provide comfort conditions than for a similar building in Perth or Sydney, which are plotted at points 4 and 5 respectively.

Extremes of temperature and humidity that exceed normal design conditions do occur and their effects on HVAC design must be anticipated: point 2 is only 1°C below the cut-out temperature for certain manufacturers’ air-cooled equipment. Hence, prudent specification and selection of equipment could avoid this being an issue. Sometimes even the best designers have to admit defeat, however. Point 6 on Figure 2 is of note, as these are the actual conditions recorded by the Australian Bureau of Meteorology at 3pm on Saturday April 16, 2016, when it reached 35°C dry bulb and 100% humidity.

The Pilbara region is of course a large one, so the design conditions at each specific locality must always be considered. For example, the town of Newman is hundreds of kilometres inland and has a much drier climate, with more extreme summer and winter design temperatures.

Fig. 3 and 4 – Damage to building by condensation (left) and mould on ceiling diffuser (right).

Fig. 5 and 6 – Filter overwhelmed by dust (left) and ceiling stained with dust (right).

Failure to design adequately for temperature and humidity will lead not only to the unacceptable discomfort of the building occupants, but also to issues with condensation as seen in Figure 3, and mould, as in Figure 4.

High temperatures can also sound the death knell for sensitive electronics where these have not been located in an adequately cooled and protected location.

Dust

The semi-arid nature of the countryside means that the wind can quickly whip up dust in any part of the region. This, when combined with the local effects of mining or other industries can lead to extremely high dust levels, which can quickly overwhelm normal HVAC filtration, as can be seen in figure 5.

While the specific situation shown is extreme and exacerbated by the close proximity of a packaged air-conditioning unit to ore stockpiles, it does serve as a warning to the unwary designer that local conditions must not be taken for granted or else dust contamination issues within the conditioned environment will be experienced as seen in figure 6.

Additionally, ingress of dust into sensitive parts of equipment that have not been sealed against the ingress of dust soon leads to failure.

Extreme weather events

Intermittent episodes of high winds and heavy rains are typical in the Pilbara throughout the wet season which generally lasts from November until the end of April each year, and can occasionally be experienced during the “dry” season that makes up the remainder of the year. As discussed previously, tropical cyclones are a fact of life along the Pilbara coast, and a cyclone will often continue to wreak havoc inland as it moves southwards across the continent, bringing strong gales and deluging the interior parts of the region even after it has been downgraded in category from a cyclone to storm.

It is therefore not surprising that equipment and services located externally can be irreparably damaged if they do not incorporate the required robustness to survive such extreme events. Even the best designed equipment can become lethal airborne debris if not held down to a level of installation that anticipates the violence of such storm events.

Remoteness

A remote location means that access to HVAC systems by maintenance personnel armed with suitable spare parts is likely to be intermittent at best. Items that are widely available off the shelf in a state capital will require several days to arrive where required, by which time a building’s occupants may have decided to employ alternative more robust – if less efficient – measures to maintain comfort, and consigned the more sophisticated equipment to the scrap heap.

System operational strategies that are overly complex for building occupants are also likely to be abandoned at the first hint of an issue and replaced by a more traditional “turn it on to full, leave it running” method of operation.

BACK TO THE FUTURE

When considering the solutions that will overcome the issues outlined in the previous section, it quickly becomes apparent that many are based on good old-fashioned design and construction practices that tailor the HVAC system to meet the specific challenges that the Pilbara region presents. This does not mean that innovative solutions that enhance efficiency and comfort in less challenging locations are excluded from the region; in fact, taking measures to ensure the robustness of a system may well permit innovation to work more reliably and thus become accepted more widely.

In the following section, a number of essential measures learned from the lessons of existing problem HVAC systems are presented. When incorporated they have been shown to mitigate the issues previously outlined. These measures will also be of benefit when considering future HVAC in similarly harsh locations.

BE THOROUGH WHEN DESIGNING

Not surprisingly, HVAC systems that are successful are produced by good designers getting the basics correct.

- Understand local issues and requirements – this includes understanding the specific requirements of each location, for instance is the building located next to or over water, or are there any ore stockpiles or similar sources of airborne pollutants in the vicinity?

- Good design information is available. Be sure to comply with its recommendations – for example, AIRAH’s DA20 [1] is an excellent guide to designing HVAC for humid environments.

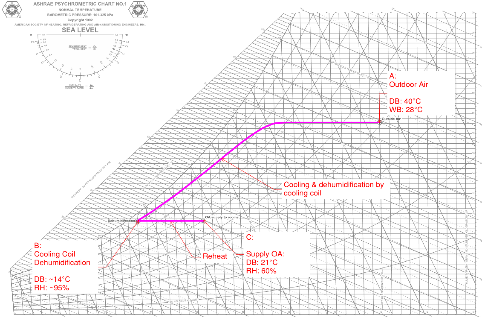

- Get the fundamentals right by performing detailed design analysis including dynamic thermal analysis, psychrometric analysis of proposed system operation (see figure 7) and detailed air balance calculations.

- To avoid condensation in ceiling voids above conditioned areas, always ensure that these are adequately ventilated with conditioned (i.e., filtered and dehumidified) air.

- Avoid over-complexity in designs – consider whether features will significantly affect reliability, maintenance requirements or the end user’s ability to use the system.

Fig. 7 – Psychrometric analysis of required processes for 100% fresh air system in Port Hedland.

KEEP THE OUTSIDE, OUTSIDE

For any HVAC system to stand a chance of working in an environment such as the Pilbara, infiltration of the hot, damp and dirty external atmosphere needs to be prevented as much as is practical. Also, buildings and HVAC need to operate as a unified whole: each should be designed to facilitate the operation of the other, hence substantially completing the building design prior to considering the HVAC is a poor design choice.

- Design the building fabric to be adequately sealed including at joints between cladding panels; between walls, roofs and floors; around window and door frames; and around all service penetrations.

- Do not introduce openings or gaps into the fabric to allow the escape of spill air – these are always a path for the ingress of untreated air from outside.

- Positively pressurise conditioned spaces, and avoid negatively pressurising any space such as a toilet or bathroom located on an external wall of a building.

- Double-glaze and insulate buildings, including the incorporation of correctly located vapour barriers.

- Use lobbies and air locks on external building entrances.

- Use separate, dedicated systems to dehumidify and filter outside air – and if you want to control humidity, provide controls that monitor and act upon humidity.

ROBUSTNESS OF EQUIPMENT AND SYSTEMS

Reliability is vital, yet harsh ambient conditions, extreme weather events, and a lack of available maintenance personnel and spare parts mean less robust systems and equipment have a substantially reduced life expectancy.

- Only specify equipment that has a reliable network for the supply of spare parts and ideally a local supplier. Tailor the system design so that the level of maintenance required is appropriate to the capacity of the maintenance personnel likely to be available.

- Specify equipment that is robust and has a quality of build that means it will be protected from environmental damage – for example, sealing around access doors and penetrations that prevent the ingress of rain and dust, and good-quality protective coatings on coils and exposed surfaces appropriate to the environment in which it is located.

- Protect sensitive electronic components such as outstations, PLC, VSD, etc., – if these cannot cope with local conditions (and most cannot) then ensure they are located within protective, conditioned enclosures.

- If equipment is not going to be located in a plantroom, use external shade devices to protect it from direct sunlight and rain.

- Ensure externally located equipment and systems are structurally sound enough and adequately tied down to withstand possible extreme weather events, including category 5 tropical cyclones where appropriate – this includes ensuring that ductwork systems are sufficiently stiffened against external wind loads and provided with shut-off dampers.

- Insulate all cold services to prevent condensation, including drip trays and condensate drainage pipework – also remember that the dew point in humid areas is significantly higher, hence the thickness of insulation may need to be consequently greater to avoid surface condensation forming.

- Condensate drainage that is undersized for the volumes of water generated has caused flooding when overwhelmed in humid areas – size all such drainage systems based on the actual flows that will be experienced at peak conditions, and provide redundancy in the number of drain outlets on drip trays.

- Understand the limitations of equipment that has been designed to sell in a wider market and that does not need to deal with the extremes of the local region. Chillers require derating, DX cooling coils that can dehumidify 100% outside air in “normal” conditions do not have the heat transfer area to cope in humid climates, and off-the-shelf packaged equipment may shut down at the external temperatures experienced locally.

- Pay careful attention to filtration – high dust-holding capacities should be specified as standard where air is drawn from outside, consider using sand-trap louvres on air intakes, and where very high dust levels area experienced, such as within 200m of an iron ore stockpile, consider using self-cleaning high-capacity filtration of the type more usually applied to industrial dust extraction and collection.

- Evaporative cooling works poorly in humid environments and fails quickly where the atmosphere contains a lot of dust.

- Most systems in the region will not be operated by qualified facilities managers or maintenance engineers, so provide logical, easy-to-operate user interfaces that will allow the occupants of a building to control their internal environment without experiencing high levels of frustration. The level of control provided should allow a degree of occupant flexibility to modify settings, but prevent the unqualified from changing key parameters essential to the correct system operation.

REMEMBER THE PEOPLE!

In regions such as the Pilbara, HVAC provides such a substantial improvement to the quality of life that for many people being without it for anything but a short period is completely unconscionable. Designers and constructors therefore have a strong responsibility to ensure they deliver reliable, working HVAC that will enhance the lives and businesses of the people of these regions throughout the design life of the systems.

CONCLUSIONS

A future where the population grows in areas where the climate is more challenging – or the changing climate presents more challenges – is foreseeable. In order for the designers and installers of future HVAC systems to excel when confronted with these challenges, it is necessary to learn lessons from the past and present.

This paper has outlined some of the issues that have occurred with HVAC systems installed at sites in the Pilbara region of Western Australia, and has provided some strong recommendations as to how future HVAC designs can overcome these issues. It is hoped that these recommendations will be used as the basis for future designs of HVAC systems in this and similar regions, and provide a foundation that will allow future innovations in HVAC design and operation to flourish.

References

(a) Books and handbooks

- AIRAH: AIRAH DA 20 Humid Tropical Air Conditioning; Australian Institute of Refrigeration, Air-conditioning and Heating (2016)

- AIRAH: AIRAH Technical Handbook 5th Edition; Australian Institute of Refrigeration, Air-conditioning and Heating (2013)

- ASHRAE: ASHRAE Handbook – 2013 Fundamentals, American Society of Heating, Refrigeration and Air-conditioning Engineers Inc. (2013)

(b) Australian Government/CSIRO website:

- Climate Change in Australia www.climatechangeinaustralia.gov.au/en/overview/

About the author

Peter Barry, M.AIRAH, is a principal engineer within BHP Minerals Australia Projects in Perth, WA. Barry’s responsibilities include overseeing designs submitted on projects for non-process infrastructure including buildings, workshop facilities, and mechanical utilities.

A highly qualified and experienced engineer, in addition to his AIRAH membership Barry is registered as a Chartered Engineer in the UK and is also a member of CIBSE, ASHRAE and the Institution of Mechanical Engineers. He has had more than 31 years of career development within major client, consultancy and contracting organisations. His responsibilities have included leading building services design teams on specialist pharmaceutical, biotechnological, industrial and commercial projects.

Peter.Barry@bhp.com