The adoption of a prefabrication strategy in the design and construction of mechanical services systems at the new Victorian Heart Hospital in Clayton solved numerous challenges associated with the build and project timelines. As Sean McGowan reports, the approach is a precursor to future healthcare projects.

Strategically located in Clayton close to Monash University and the Monash Medical Centre, the new Victorian Heart Hospital (VHH) is Australia’s first dedicated cardiac hospital to provide tailored cardiovascular care.

Accepting its first patients in early 2023, the world-class, 65,500m² health facility provides capacity for up to 206 beds. It features a full range of ambulatory and inpatient cardiac care including cardiac theatres, cardiac catheterisation laboratories and ambulatory services such as cardiac CT, echocardiography and specialist consultation.

Built by John Holland for the Victorian Health Building Authority, the VHH is the result of a partnership between the Victorian Government, Monash Health and Monash University.

Its design is the result of a joint venture between Australian architecture and design practice Conrad Gargett and architecture studio Wardle Australia.

Winner of an Inde Award for the best design in the Health and Wellbeing Space in August last year, the design of the VHH “emphasises enhancing the human experience by connecting the mind and body with multi-sensory and enriching environments.”

“Guided by biophilic design principles and a salutogenic approach, the architecture, interiors, facility planning, and clinical planning consider the built environment’s impact on the health and wellness of patients, clinicians, staff, researchers, students, carers and visitors,” say the collective.

At the centre of the hospital, an open, landscaped courtyard has been designed to bring the visual relief of nature across all eight stories of the building. It allows natural light to permeate the surrounding spaces, with its circular form connecting the community of the hospital for rest, respite and gentle activity.

Future flexibility was also key to the health facility’s design, both in relation to space planning and the incorporation of building services and structural systems that can adapt to future clinical care technologies and patient needs.

A prefabricated approach

Working with mechanical services engineer AECOM, A.G. Coombs delivered the mechanical services contract on the project, commencing with early contractor involvement (ECI) in late 2019.

“ECI engagement offers numerous opportunities to enhance project outcomes and is very important on complex healthcare projects such as this,” says Kevin Wilson, senior project manager at A.G. Coombs Projects.

He says as a consequence of this early engagement, his team was able to complete engineering and building information modelling (BIM) 15 months prior to the scheduled practical completion date.

“This put us and the project in a good place in regard to procurement, works programming and, ultimately, prefabrication,” Wilson says.

The project represents a watershed moment for the A.G. Coombs Group – and the mechanical services contracting sector more generally – with almost 30 per cent of construction hours spent prefabricating mechanical services systems components offsite.

Wilson says the company’s vision is to apply prefabrication on all projects, with nothing off the table.

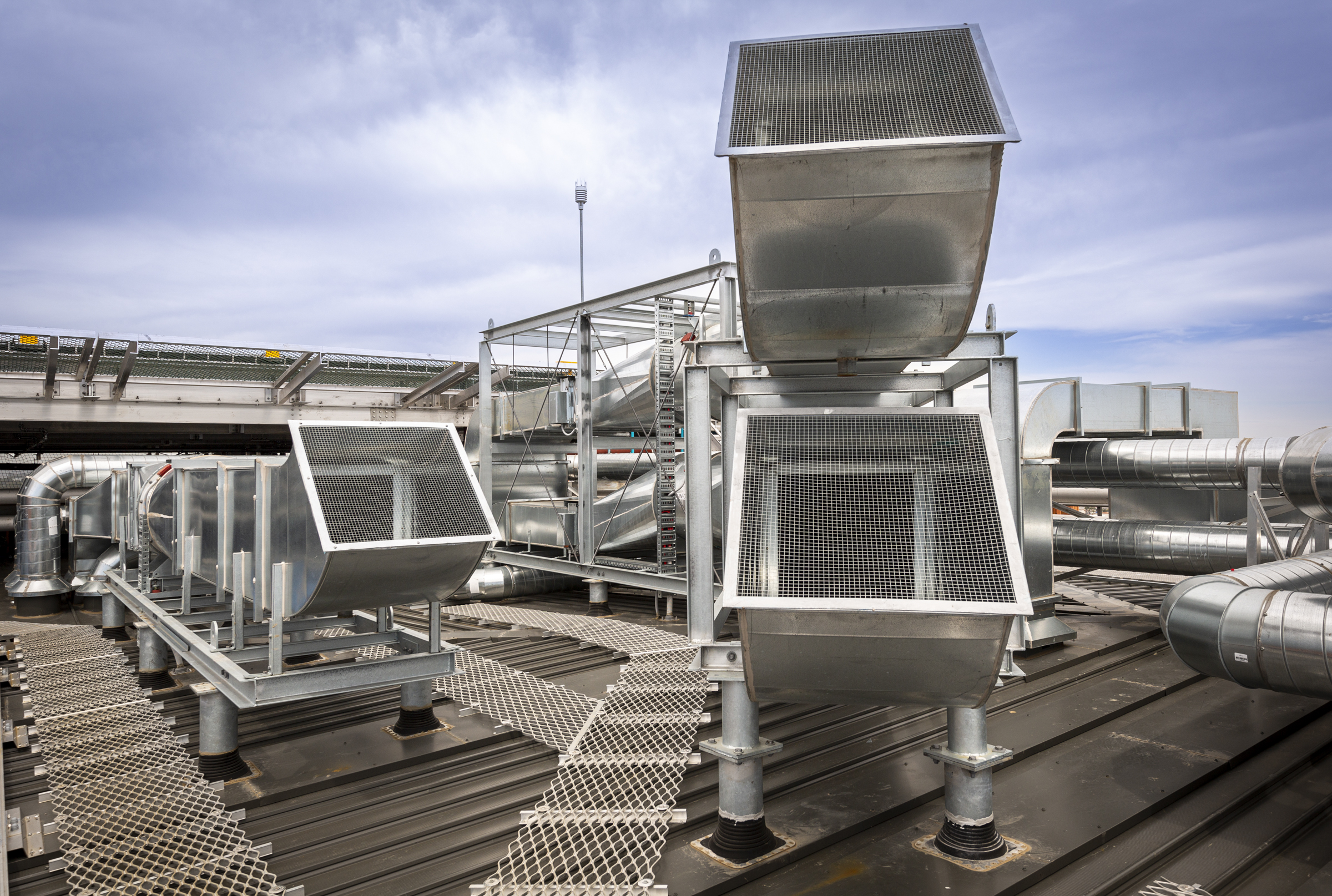

“The VHH had a significant and complex plantroom and rooftop plant that lent itself to offsite prefabrication to assist with quality and construction program efficiencies,” he says.

This strategy also created a safer working environment for the company’s workforce, and alleviated some of the inevitable delays associated with Melbourne’s weather.

Heart numbers

Each year, the Victorian Heart Hospital is expected to deliver:

- 28,000 emergency patient assessments

- 10,000 interventional cardiac catheterisation procedures

- 2,000 open-heart surgeries.

Air handling units were designed with both air‑to-air heat recovery, run-around coils and premium efficiency EC motors.

Fume cupboard exhaust.

Incorporating prefabrication

According to A.G. Coombs Projects’ Daniel Waack, M.AIRAH, all projects are suitable for prefabrication and offsite manufacture.

“For us, prefabrication forms a fundamental part of how we deliver projects,” Waack says. “So as soon as we were awarded the VHH project, elements of prefabrication were being incorporated and considered.”

He says the process of incorporating prefabrication into the design centres on influencing key design decisions and parameters so as to not limit its use or potential.

“There are several areas of influence,” he says, “including the installation methodology, services design, and structural integration.”

Installation methodology

This relates not just to services but to the surround structure. Often prefabricated solutions are larger and heavier than components for a conventional build, so therefore consideration of access and installation sequencing is crucial.

Services design

Coordinating services and surrounding items to maximise the use of a prefabricated frame structure, and locating the frame within the building, often calls for counterintuitive design and layouts – all the while maintaining safety in design and future maintenance and access requirements.

Structural integration

In order to minimise the use of redundant steel, the most successful cost-effective solutions are highly integrated with other services and structures. In the case of VHH, the weight bearing elements for the roof plant platforms were coordinated and tied into the main roof structure.

Complex HVAC services

The key systems installed under the mechanical services contract at the hospital included the facility’s HVAC system, medical gases, pneumatic tube, waste chutes, building management system (BMS) and emergency management system (EMS).

The thermal central plant is designed with both energy efficiency and redundancy in mind, providing resilient heating and cooling to the facility, with dual-fuel boilers serving the hospital’s heating hot water (HHW) and domestic hot water (DHW) demand.

With high outside air rates required to meet the hospital’s ventilation needs, air handling units (AHUs) were designed and installed with both air-to-air heat recovery, run-around coils and premium efficiency EC motors.

To this end, contractor and consultant worked closely with the supplier to design, select, model, coordinate and manufacture 160 air handling and fan coil units (FCUs) to meet the construction program and the sequential nature of the required delivery.

Space provisions for plant, capped duct risers and spare capacity in systems were also included in the mechanical services design to cater for the future fitout of shell spaces.

Specialist systems were also provided to dedicated spaces within the facility including the Monash University Research and Teaching PC2 Laboratory, operating theatres, catheterisation laboratories, the central sterile supply department (CSSD) and isolation rooms.

To deliver a complex, multi-compartment fire mode strategy, A.G. Coombs Projects called on the group’s technical capability and previous experience in the healthcare sector.

This strategy met the challenges associated with the floor and department layouts of the VHH, and successfully maintains critical pressure regimes in operating theatres, catheterisation laboratories, isolation rooms and the university’s laboratory space.

A number of innovative prefabrication solutions were employed in the construction of this complex mechanical services design, including specially-developed “roll in” risers – the largest measuring 12m by 6.2m.

Able to be wheeled into the riser penetration at each floor level, this method overcame challenges that restricted the use of traditional drop-in risers. The approach has since been repeated by A.G. Coombs on other projects.

Other solutions employed in the construction of mechanical services at the VHH include prefabricated pump skids, riser frames, roof fan skids, coil valve assemblies and the prefabrication of 4.3km of horizontal chilled beam pipework modules.

By maximising prefabrication opportunities wherever possible, not only were the construction challenges identified early on able to be overcome, but parallel construction aided in the mechanical services construction being completed to schedule.

According to A.G. Coombs Projects integrated prefabrication leader Daniel Waack, M.AIRAH, the capacity for parallel construction proved crucial on this project, which was completed under the cloud of the COVID-19 pandemic.

“Having the ability to strategically complete work in a controlled environment with less foot traffic lowered the risk of infection and moved some of our people off the more crowded construction site,” Waack says.

Perhaps more importantly – and certainly more applicable to projects built since the pandemic – is that prefabrication also allows for safer build.

“This was most apparent in the 16m high isolation room roof exhaust stack installed on the side of the VHH building,” explains Waack.

The hospital earned a plaudit at last year’s Inde Awards for the best design in the Health and Wellbeing Space.

Shading on the high-performance facade.

Fire mode

The Victorian Heart Hospital has been designed with some 57 different fire/smoke zones – some are quite small while others are very large, extending across three levels of the building.

Among the fire/smoke zones were high-priority spaces such as operating theatres and pressure-controlled PC2 laboratories that, where possible, needed to remain operational in a fire event while still meeting the needs of the Fire Engineering Report (FER).

To ensure both patient safety during a fire event, while also minimising disruption to others parts of the hospital, a complex, multi-compartment fire mode solution was employed that required early coordination with the project’s fire engineer AECOM.

“The complexity meant that clear documentation in the fire matrix and commissioning layouts was critical to ensuring all of the systems were correctly installed, wired and commissioned,” says Kevin Wilson from A.G. Coombs.

The Monash University Research and Teaching PC2 laboratory involved a significant amount of coordination between the design team and the various specialist system contractors. This was due, in large part, to the fume cupboard exhaust designed in a manifold arrangement that serves seven fume cupboards located in a variety of rooms. This system is then served by duty/stand-by strobic fans on the roof.

A total of 35 laboratory VAV units control the total volumetric flow into and out of each space, adjusting to suit the fume cupboard sash positions. Five snorkel exhaust arms are also included in the design, with provision for another nine.

Once construction was completed, the required pressure regimes throughout the laboratory then had to be commissioned with all of these dynamic systems in play.

Prefabrication allows for safer construction. This was most apparent in the 16m high isolation room roof exhaust stack installed on the side of the VHH building.

Early influence

According to A.G. Coombs’ Kevin Wilson, early contractor involvement (ECI) is a game changer on most projects. But this is especially the case on complex healthcare projects such as the Victorian Heart Hospital.

“Early involvement of the contractors allowed for significant value management initiatives to be incorporated, and both buildability and commissionability to be considered in the design,” he says.

The early involvement of the mechanical contractor enabled it to have influence over the design and strategy of the project delivery to maximise the use and benefits of prefabrication.

“The marriage between John Holland, AECOM and A.G. Coombs allowed us to workshop and delivery industry best practice solutions while also focusing on program and budget requirements,” Wilson says.

“ECI allows all this to occur at the most crucial point of a construction project – concept day one – and allows design flexibility to be integrated while mitigating design rework. It also shapes the architectural spatials required for the efficient design, future service and maintenance access and plant replacement.”

Tuning and training

The BMS serving the VHH controls complex clinical spaces such as operating theatres, catheterisation laboratories and CSSD areas, along with cascading pressure regimes required for infection control and zone temperature and humidity.

The system interfaces with metering to allow building tuning outcomes to be achieved. This helps maximise operational control and energy usage.

“Fault and failure alarms are also a key aspect of the BMS to notify the Monash Health facility management team of any urgent or immediate actions needing to be taken to ensure the facility is operating as designed, given the primary outcome is the care and healing of the sick and vulnerable,” says Wilson.

An intensive six weeks post-completion were dedicated to the commissioning of the mechanical services systems, ensuring they functioned as designed in accordance with Australian Standard AS1668.

Monthly building tuning meetings have since been held alongside the delivery of mechanical services maintenance by A.G. Coombs Service during the 12-month defects liability period (DLP). These have focussed on energy efficiency given mechanical services typically represent 75 per cent of a hospital’s energy consumption.

To date, improvements to the coefficient of performance (COP) of chillers, boilers and air handling systems have been sought, with a dedicated energy monitoring system providing real-time energy usage and trends for all services.

Client training has also been prioritised to ensure Monash Health personnel are familiar with the operation of the services within the building.

“I am extremely proud of the outcome at the Victorian Heart Hospital, and the quality of installation that our team has achieved,” says Wilson, adding that the lessons learned from this project are already being applied to other healthcare projects.

A.G. Coombs is now completing the fitout of mechanical services to a number of shell spaces within various areas of the hospital, including CT scan room, a short-stay area and catheterisation laboratory procedure room.

The VHH had a significant and complex plantroom and rooftop plant that lent itself to offsite prefabrication to assist with quality and construction program efficiencies.

Project at a glance

(Source: A.G. Coombs)

The personnel

Architects (joint venture): Conrad Gargett, Wardle Australia

Consulting engineer (multidisciplinary): AECOM

Developer: Victorian Health Building Authority

Head contractor: John Holland Group

Mechanical services contractor: A.G. Coombs

Mechanical services electrical: Butler Electrical

The Equipment

AHUs: GJ Walker

BMS: Schneider Electric

Boilers: Automatic Heating

Chilled beams: Frenger

Chillers: JCI

Cooling towers: BAC

Coolrooms: Total Coolrooms

Controls: Schneider Electric

CRACs: Stulz

Duct: Ductmakers

Exhaust hoods: Ecocanopy

Fans: Fantech

Filters and strobic fan: Airepure

Fume cupboards: Conditionaire

Grilles: Shapeair

Heat exchangers: Fluidpro

Humidifiers: Condair

Laboratory exhaust arms: Nedermen

LVAVs: Siemens

Pneumatic tube: Lamson

Pumps: BKB Building Solutions

Smoke curtains: Smoke Control

VAVs: Celmec

VAV diffusers: Rickard

VSDs: Danfoss

Waste/Linen chutes: Elephant Foot