Arch of triumph

A multi-award winning, mixed-use development in Melbourne’s prestigious Collins Street has brought building managers, service technicians and energy optimisation specialists together to collaborate on operational performance improvements post-completion. Sean McGowan reports.

Completed in 2020 for owners Cbus Property and ISPT, the world-class Collins Arch development at 447 Collins Street spans an entire city block, with its pair of tapered towers – connected by an elevated sky bridge – soaring 164m above street level.

The distinctive design by SHoP Architects and Woods Bagot has claimed several awards, including The Sir Osborn McCutcheon Award for Commercial Architecture at the Australian Institute of Architects’ 2021 Victorian Architecture Awards.

Buildings that previously occupied the site include the c.1841 Western Market and the 1960s-built National Mutual Centre – itself a mixed-use building combining offices with a ground-level shopping plaza.

A striking addition to the skyline of Melbourne’s financial district, the dual-structure of Collins Arch offers 49,000m² of premium-grade, WELL-rated commercial office space across 24 levels, as well as 184 luxury residential apartments and the new 294-room W Melbourne hotel.

A multi-level retail podium spans the base of both towers to activate the street frontage, while the city’s first new public park in 40 years has been created as part of the development.

Woods Bagot says that through the use of vertical stacking, each floorplate has been optimised to dedicate half of the site back to the city as public spaces.

“The permeable ground plane combines a series of outdoor rooms, a new urban park and programmed edge conditions to create a diversity of experiences for workers, residents and visitors to enjoy,” says the architect.

The commercial floors occupy the lower and middle portion of the western tower, and feature a side core that “lends flexibility and spaciousness” to each workplace.

A twin lobby system provides access to the commercial floors from either tower.

The hotel and residential apartments occupy the development’s arch and the floors above it. The design has incorporated a variety of apartment types and sizes, all with access to views, natural ventilation and daylight.

Amenities include an indoor pool, gymnasium, lounge area, dining facilities, private outdoor terraces and a shared sky garden.

Under management

Property management firm JLL was awarded the contract to manage the commercial office spaces, common areas and key logistical elements on behalf of the owners while 447 Collins was still under construction.

The full-suite property-management role includes all engineering, risk and sustainability.

After the development reached practical completion in March 2020, JLL’s operational team engaged A.G. Coombs Advisory as it transitioned through the defects liability period (DLP) to tuning and ongoing building operations.

Working collaboratively with JLL and the building owners, A.G. Coombs Advisory’s multidisciplinary team acted as an independent third party throughout this period. It also provided a peer-review service during the control system DLP.

Given the complexity of fire modes operating across the site, works initially focused on the commissioning of fire services testing, the development of fire-mode matrices, and fire system gap analysis.

Drawing on shared experience and a mutual trust developed over several years on other properties, JLL later extended the scope of the contractor’s engagement. This has included the provision of mechanical services maintenance to common areas, retail spaces, W Melbourne and key tenancies under a preventative maintenance model by the firm’s service arm.

The building’s owners and managers sought to drive building performance optimisation.

“HVAC optimisation works were undertaken soon after practical completion to achieve aspirational 5.5 star NABERS Energy and 5 star NABERS Indoor Environment ratings as the first ratings of the asset,” says Selva Thiru, senior engineering and operations manager for JLL.

“This sets the tone for future years.”

Plantroom walkthrough

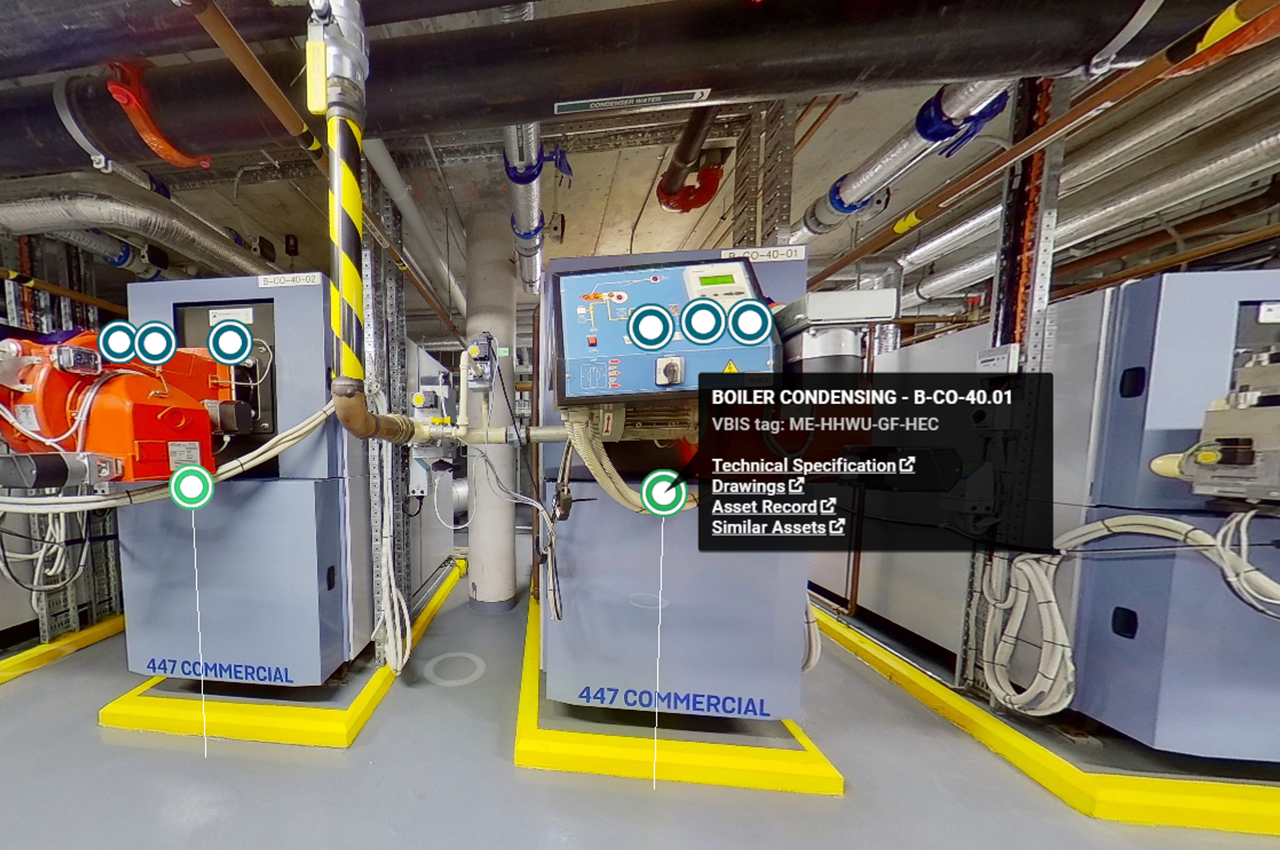

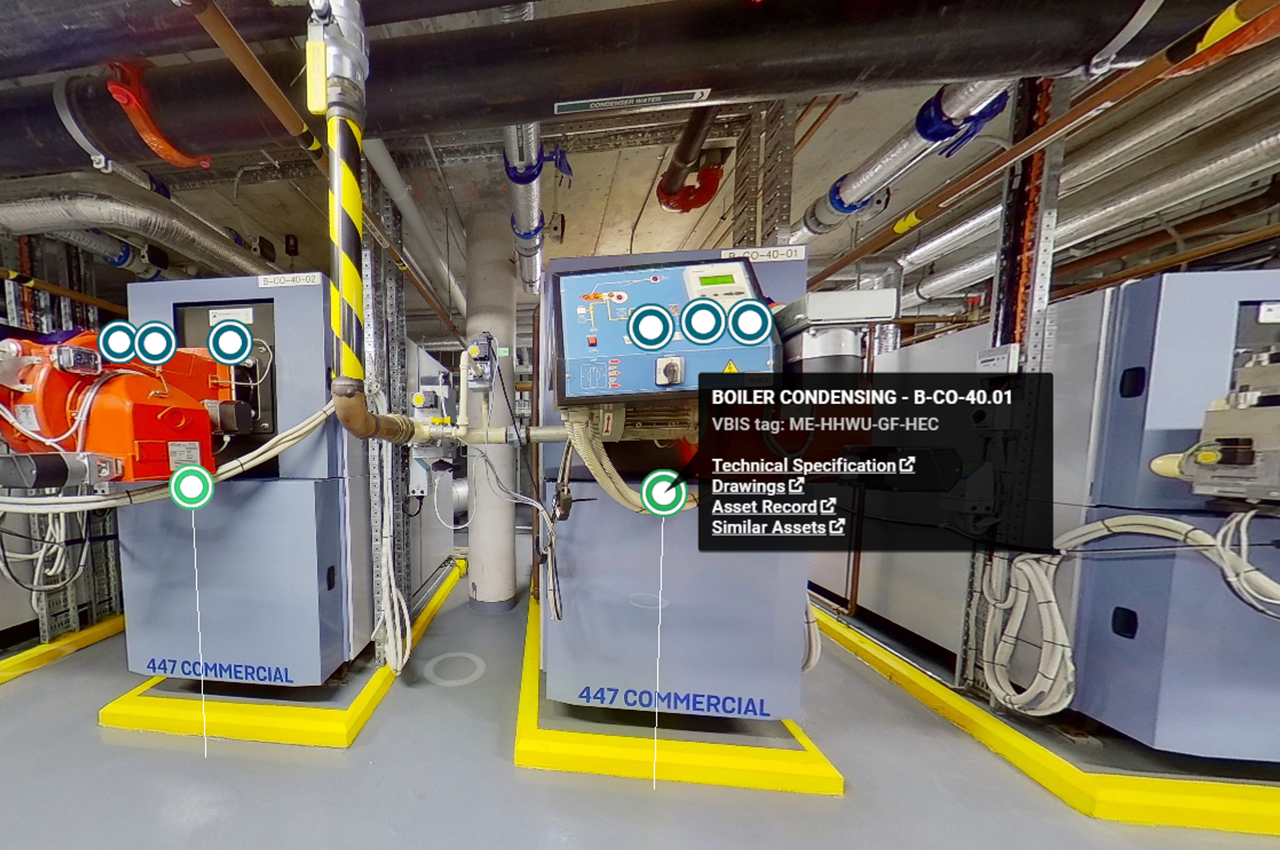

Working with JLL, A.G. Coombs Advisory has completed three-dimensional, 360-degree photographic scans of every plantroom at 447 Collins to create a digital twin that allows the user to navigate a virtual walkthrough.

The scans have included tags on equipment that provide additional equipment photographs, technical data sheets and drawings, and maintenance management systems.

These walkthroughs have been further enhanced with virtual building information system (VBIS) tagging. This provides a comprehensive asset classification by identifying equipment and linking connecting data such as technical specifications from the manufacturer.

“VBIS tagging has been used to link data from each of the disparate systems to deliver connectivity of the data between the systems,” says Andrew Smith from A.G. Coombs Advisory.

“This allows the end-to-end connectivity between building systems to the analytics, on to the graphic visualisation interface, the 3D views and finally connecting into technical data and the maintenance management system.”

To provide an understanding of how these technologies advantage those responsible for building services maintenance onsite, A.G. Coombs Service’s Ken O’Brien provides the example of a technician querying the operation of an item of plant.

“At their fingertips, accessible via PC or tablet, is the commissioning data and operation manuals of that item of plant,” he says. “Not only is this valuable to help with fault rectification, but it ensures the plant is set to operate as it was intended.”

Fire mode

As part of A.G. Coombs Advisory’s remit, it was engaged over a three-year period to provide professional fire safety advice and high-level coordination of the integrated fire mode testing. The aim was to ensure the building fulfils fire service maintenance requirements in accordance with AS 1851-2012.

“This work forms part of the building’s essential safety measures (ESMs) obligations, including annual compliance certification,” says Marcus Royle, senior engineer (fire) for A.G. Coombs Advisory.

Royle says that due to the building’s mixed-use nature, this work prompted identification of potential operational interface issues and system complexity, both of which posed difficulties to manage and verify the appropriate system function as a holistic fire mode operation.

“To assist with this, we proposed a staged approach,” he says.

“The first was to review and collect available documentation of the current fire safety systems and commissioning data. These findings were then consolidated into a single technical report detailing a basic description of the system components and the intended operation, as well as an integrated fire-mode testing matrix.”

The second stage would see a test script report developed that detailed the testing sequence and anticipated operation of the building. This would be used as a procedure document for ongoing integrated fire mode testing.

“The investigative testing highlighted any defects and observations that are required for rectification,” says Royle. “And these results were then used to refine the documented matrix for a functional fire strategy.”

The final stage includes a second and third-year contract term for ongoing annual witness testing and reporting.

Located at 447 Collins St, Collins Arch offers WELL-rated commercial office space across 24 levels.

On the ground at 447 Collins

ON THE GROUND AT 447 COLLINS

Ken O’Brien, senior contract manager at A.G. Coombs Service, provides further insights into the company’s engagement at 447 Collins.

Encourage conversations. Constructive discussion followed by action equals results.

- Get the team right. Well trained, empowered and supported field technicians with a sense of ownership make a huge difference. Couple this with a lateral-thinking building energy optimisation program engineer and you will see results.

- Keep your asset information accurate, well documented, and up to date.

- Make analytics reporting, energy dashboards and equipment information easily accessible for all parties.

- When optimum energy performance is a focus, even the smallest things matter – like an air leak in a plenum, or a poor-performing VAV.

- Collaboration of all parties. Building owners, building managers, building energy optimisation program engineers, technicians and sub-contractors – everyone has a role to play.

Service delivery

According to A.G. Coombs Service senior contract manager, Ken O’Brien, a condition of the mechanical services maintenance contract with JLL centred on the quality and type of technician to be engaged at 447 Collins.

A.G. Coombs Service has a dedicated, experienced technician embedded with the JLL facilities team in the building during business hours.

As well as becoming a trusted member of the onsite team, their presence ensures familiarity of the building services and the variety of spaces. It also allows for continued monitoring of operation and analytics outputs.

Most service and maintenance works are completed inconspicuously to limit disruptions to building tenants, residents and guests.

“There a many different stakeholders at 447 Collins,” says O’Brien, “so appreciating their drivers and communicating clearly is key.”

For instance, technicians have had to navigate the challenges of pin-pointing responsibility for issues where tenant fitouts were still under DLP.

Similarly, plantrooms contain an array of equipment managed by different parties.

“We can find commercial, hotel and residential equipment all in the same plantroom,” says O’Brien, “or even a piece of plant serving two different entities.”

A.G. Coombs’ Service and Advisory arms have worked in unison to provide reporting, analytics and dashboards that assist both the client and service personnel in early identification of issues, as well as improving energy usage and conditions.

Ensuring accurate asset lists and naming conventions linked with easily accessible equipment specifications, drawings and design data means that personnel can keep the building operating as intended.

“Small things like doing a hot/cold/draft call are simplified when our technician can review trends, quickly access the design requirements of a VAV system on the spot, and check the balance is accurate and adjust if necessary,” says O’Brien.

“Having the right feet on the ground combined with good dashboards, plus a collaborative client in Selva and the JLL team, means delivery from a contractual and operational perspective is made efficient.”

Each floorplate has been optimised to dedicate half of the site back to the city as public places.

Building efficiency

Through the introduction of various leading-edge technologies, the two firms are seeking to optimise the management of complex interactions between mechanical services and systems, and the site’s different spaces.

This end-to-end integration of technologies began with the implementation of a Building Energy Optimisation Program (BEOP), which seeks to improve the building’s energy performance and carbon footprint.

“BEOP is unique in its proactive approach to both tune and optimise the performance of a site without relying solely on the outcomes of add-on analytics-based learning,” says Andrew Smith, leader of building technologies at A.G. Coombs Advisory.

The program kicked off with a comprehensive audit and report of the control systems and building services. This established systems configuration, operating strategies, performance, and opportunity for improvement.

Other elements included the initial tuning of systems. They are currently configured to achieve predictable, repeatable and stable control.

“This tuning is not just limited to building control systems,” Smith says. “But also considers the building services configuration itself to determine if capacity and configuration are correct for the application.”

The program uses analysis of building system performance data to determine the building’s operational profile, including baseline energy consumption and behavioural impacts.

This work led to further investment in technologies, including analytics software, which collects real-time operational data from systems such as the building automation system (BAS) and energy management system (EMS).

Using rules applied to the data, it has been used to drive building efficiency during the tuning period. It also provides energy management and operational insights to instruct maintenance.

To provide greater visibility, an advanced visualisation technology has been implanted. This dashboard provides the onsite team with a graphical interface, which provides performance and operations monitoring in real time, playback of historical events, and fault visualisation.

“Prior to implementing the platforms, collating vast amounts of data was the challenge, as was visualisation to understand the true state of the asset,” says Thiru.

“We have focused on ensuring the platform is accurate and reflects the true state of the asset, which has then contributed to a more robust tuning program to achieve our goals.”

As the technologies deployed at 447 Collins become further embedded and trusted, it’s thought the mechanical services maintenance model may be able to move to a data-driven hybrid model.

“Maintaining and improving on NABERS ratings, sustainability and property technology at 447 Collins remain a strong focus – ultimately providing a better outcome for the occupiers of the building and the community at large,” says Thiru.

“But none of this would be possible without the strong support and commitment from the owners.”

Lessons from the property manager

Selva Thiru, senior engineering and operations manager for JLL, shares some of the lessons to have come since practical completion was reached at 447 Collins.

- The onsite engineering team need to be equipped with the knowledge of how to use and/or analyse big data.

- A robust, comprehensive DLP program is essential for future outcomes.

- Initial site setup post-practical completion is key to the success of the asset.

Project at a glance

The personal

Architect: SHoP Architects + Woods Bagot

Building Management: JLL

Building Owners: Cbus Property and ISPT

Building Performance Consultant: A.G. Coombs Advisory

Mechanical Services Contractor: A.G. Coombs Service

The equipment

Advanced visualisation platform: DGLux

Analytics software: SkySpark

Plantroom walkthroughs (3D): Mattaport

Virtual tagging: VBIS

This article appears in Ecolibrium’s June-July 2022 edition

View the archive of previous editions

Latest edition

See everything from the latest edition of Ecolibrium, AIRAH’s official journal.