Streamlining electrification in support of decarbonisation

Abstract

Our industry has increasingly focused on the electrification of building utilities coupled with low-carbon electricity to support the global decarbonisation effort. Examples include the University of California’s system-wide ban on the use of on-site fossil fuel combustion in new construction and major renovations, and the City of Seattle’s recently passed measure to prohibit the use of natural gas for space heating in new construction and major replacements of heating systems in commercial buildings, as well as for water heating in new hotels and large apartment buildings.

This column presents an approach to integrating the production of domestic hot water with an electric heat-recovery chiller plant as a streamlined solution.

The following two case studies, involving a stand-alone building utility plant and a plant that ties into a campus chilled water system, demonstrate the flexibility of this approach.

Case study 1: Southern California medical office building

The first application is based on a new-construction125,000 gross ft² (11,600 gross m²) outpatient medical office building located in the coastal region of Southern California. This project required local, dedicated HVAC and plumbing utilities. The author served as a member of a design-build team to evaluate various HVAC and plumbing design options to determine the best-value solution based on merit. Figure 1 illustrates the baseline design approach to which our proposed approach, shown in Figure 2, was compared.

The baseline approach was developed according to prescriptive and qualitative requirements stipulated in the owner’s request for proposal (RFP) package. This included the requirement to provide an electric-powered utility plant that incorporates heat pump and heat-recovery chiller technology to produce heating hot water (HHW), chilled water (CHW), and domestic hot water (DHW) utilities for the proposed building. Heating hot water and chilled water are produced from a string of four modular heat-recovery chillers sized to meet building heating demands combined with three supplemental air‑source chiller (CH) modules to accommodate peak cooling demands.

Each heat‑recovery chiller and cooling-only chiller module is furnished with a set of integral automated isolation valves that are controlled by a factory controller to modulate output and prevent bypass of chilled and heating hot water through inactive modules under normal operation. Four identically sized air-source heat pump domestic water heaters (HPWH) with remote storage tanks are provided to meet the demand for domestic hot water.

The owner’s RFP encouraged design-build teams to consider and propose alternative design solutions basedon merit to the project and owner. To that end, our team considered options that had the potential to achieve as many of the following attributes as possible:

- Lower first cost;

- Lower maintenance;

- Better or similar energy-efficiency performance; and

- Reduced mechanical room space requirements.

The integrated domestic water heater design approach shown in Figure 2 provided a compelling option to simultaneouslyachieve as many of the aspirational goals listed above aspossible. The proposed approach consists of two identically sized dual-source tank-type water heaters that use the HVAC heating hot water utility to preheat the domestic cold water(CW) feed from ~60°F (~16°C) to ~110°F (~43°C) with auxiliary electric resistance element heaters as the second heat sourceto lift the w he heat-recovery chillers were initially sized to provide an aggregate heating capacity of 2,495MBtu/h (731kW) based on a selection of four equally sized “60 ton” modules to meet a design heating load of 2,106MBtu/h (617kW) during a design heating condition, providing a peak heating hot water supply temperature of 115°F (46.1°C). This yields 389MBtu/h (114kW) of “spare” capacity that enables consideration of the proposed approach of integrating the domestic hot water production.

Additionally, because the chiller modules have hardware similar to that of the heat-recovery chiller modules, it is possible to consider conversion of cooling-only chiller modules to heat-recovery modules to provide additional heating capacity, if needed, without adding extra compressors or heat exchangers to the proposed system.

There is more than one way to integrate the production of domestic hot water with HVAC heat-recovery chillers; the following evaluation of desired design attributes

will clarify why the author and design team arrived at the solution proposed. The author encourages designers and owners to carefully evaluate desired performance metrics on a case-by-case basis to arrive at the optimum solution for each application.

First cost

The proposed approach of integrating domestic hot water production with the heat-recovery chillers yielded first cost savings of approximately $225,000 compared to the baseline approach through reduced equipment and installation costs. This was primarily achieved through a reduction in the quantity of equipment required, as well as the elimination of heat pump modules from the domestic hot water equipment. Installation cost savings can scale quickly when the quantity of installed equipment can be reduced. In this case, a minimum of four of the largest modular commercial heat pump water heaters available to the project are required for the baseline approach versus two custom dual-source tank-type water heaters for the proposed approach. Although custom equipment often comes with a cost premium, in this case it yielded significant equipment cost savings through the elimination of heat pump equipment from the water heaters and reduced installation cost (both labor and materials).

Maintenance

Albert Einstein has been quoted as stating that “everything should be as simple as possible, but no simpler.” The proposed approach to produce domestic hot water through a combination of heating hot water preheat and electric resistance booster heat approaches this ideal by eliminating additional heat pump components such as refrigeration compressors, refrigeration circuits and associated appurtenances, and evaporator fans. This represents a substantial simplification and reduction of future maintenance needs compared to the baseline heat pump water heater system shown in Figure 1.

Energy efficiency

The design team anticipated that, under conditions where there is no simultaneous demand for chilled water production, the baseline approach of using dedicated stand-alone heat pumps to produce domestic hot water could have an energy-efficiency advantage over the proposed hybrid system that uses HVAC heat pumps for part of the load with electric resistance heat to boost the domestic hot water to storage temperature.

The HVAC heat pumps generally have a coefficient of performance (COP) similar to that of the latest commercial-grade domestic hot water heat pumps in a heating-only condition comparison. However, the HVAC heat pumps used in the proposed system can produce chilled water simultaneously with heating hot water, which yields a COP that is substantially higher than the heating-only COP of either machine.

This is a strategic advantage of the proposed approach for buildings with substantial simultaneous demand for chilled and domestic hot water, which can be the case for medical office buildings in Southern California. It is also an inherently less wasteful process from an exergy perspective, as the coupling of domestic hot water production with heat-recovery chillers eliminates the potential for the HVAC plant to be rejecting heat to the atmosphere while the domestic hot water heat pumps are pulling heat from the atmosphere, which is anticipated to occur from time to time with the baseline design shown in Figure 1.

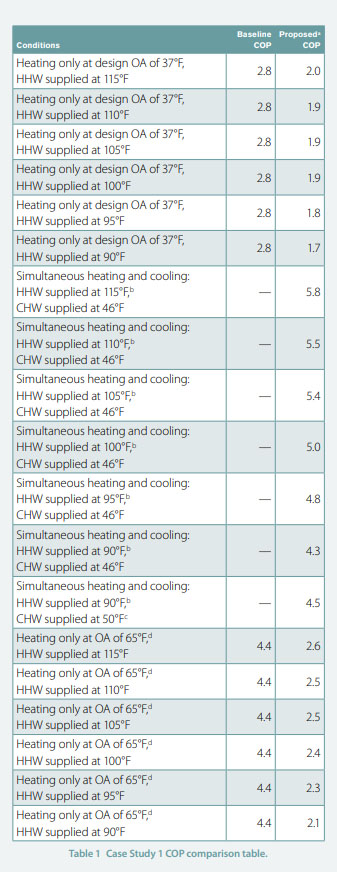

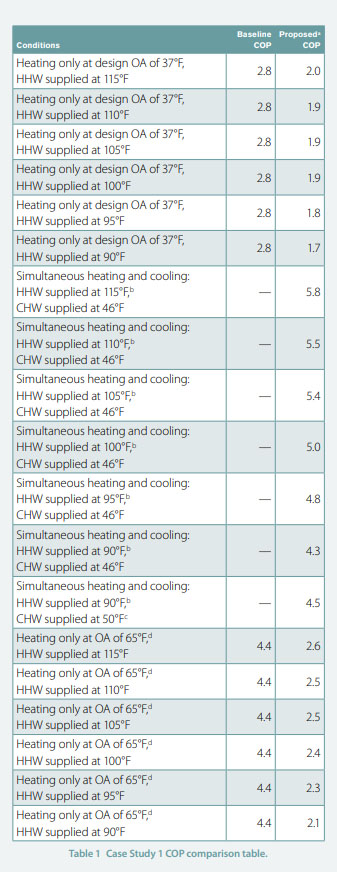

Table 1 summarises the COP comparison between the baseline and proposed approaches under a variety of operational and ambient climate conditions.

a Proposed COP is based on aggregate performance between domestic hot water load served by HHW and load served by electric resistance heat.

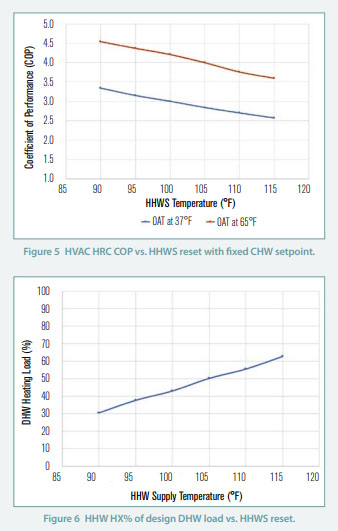

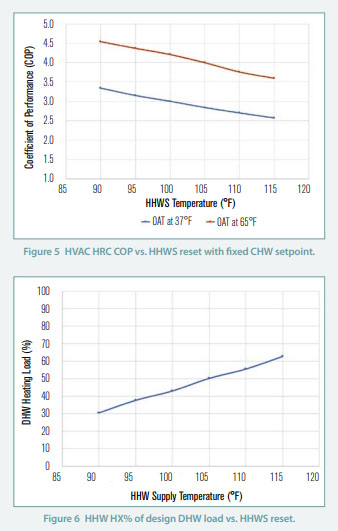

b Multiple HHW supply temperature operating points were reviewed to evaluate potential energy efficiency gain from resetting HHW supply temperature.

c Maximum CHW supply temperature operating point reviewed with minimum HHW supply temperature operating point to evaluate potential energy efficiency gain from resetting both HHW and CHW supply temperatures.

d Mild weather condition to evaluate anticipated performance

at intermediate ambient climate conditions.

The relative operational efficiency of the proposed approach to integrate domestic hot water with the HVAC heating hot water system against the baseline approach of providing dedicated stand-alone heat pumps to produce domestic hot water is highly dependent on operational characteristics of the building heating hot water and domestic hot water demands as well as on the ambient climate conditions.

Overall, under the operational characteristics and climate that apply to this case study project, the energy efficiency of the two approaches could be described as similar. The difference in annual energy performance on a project site energy use intensity (EUI) basis is anticipated to be within 1%, with the dedicated air-source heat pump water heaters in the baseline design having the slight advantage according to our energy model during the design process.

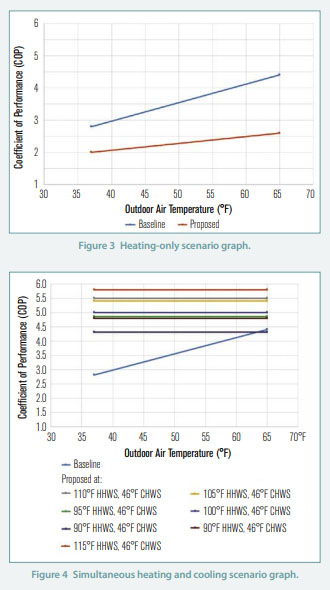

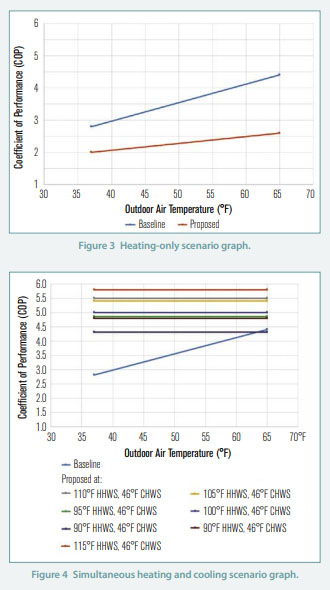

This conclusion makes sense; although the baseline design has superior COP under heating-only conditions (Figure 3), the load profile of this project is such that there is significant simultaneous demand for heating and cooling within the building, a circumstance in which the proposed design has significantly higher COP (Figure 4). Another factor contributing to the small impact on overall project EUI is the relatively small magnitude of the domestic hot water energy consumption compared to other energy loads within the building.

During our COP analysis, it became clear that resetting the heating hot water temperature produced by the HVAC heat‑recovery chiller had a significant impact on the aggregate COP of the proposed dual-source domestic hot water heater design approach. While the HVAC heat-recovery chiller COP improved significantly with reduced heating hot water supply temperatures, the heat transfer done by the heat exchanger served by the heating hot water was simultaneously reduced by a substantial amount (Figures 5 and 6). Given that the building heating and cooling loads are orders of magnitude greater than the domestic hot water load, it is prudent to reset heating hot water and chilled water supply temperatures based on demand to achieve the best overall building energy performance.

To accommodate the reduced heat transfer done by the heating hot water heat exchanger within the dual-source domestic hot water system, the author recommends sizing the auxiliary electric resistance heater to handle the full domestic hot water

load with silicon-controlled rectifier (SCR) modulating output control to both allow for maximum flexibility in heating hot water supply temperature turndown and provide a margin of redundancy in the event of a service outage from the HVAC heat-recovery chillers.

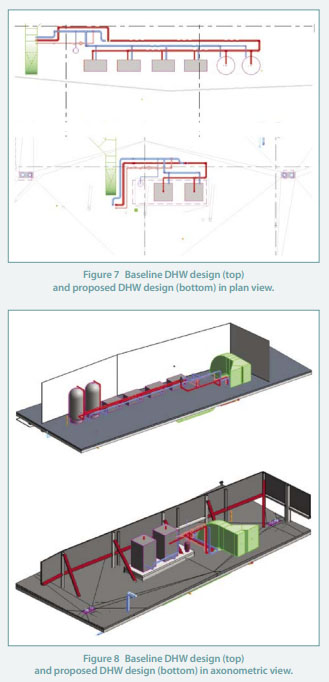

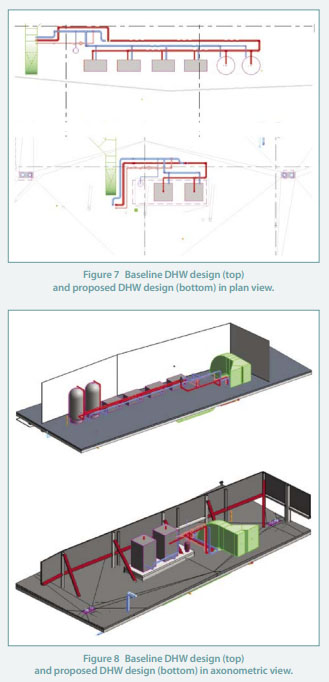

Reduced mechanical room space requirements

Our team found that the proposed dual-source domestic hot water heater design yielded a substantially more compact layout than the baseline design using dedicated air-source heat pumps piped to remote storage tanks. Although this matches our expectations based on the fundamentals of air‑source heat pumps requiring substantial space due to their associated heat exchangers, laying out both options in our design modeling software illustrated this advantage to a degree that our visually inclined design team could appreciate (Figure 7 and Figure 8).

Case study 2: Southern California higher education academic instruction building

The second example is a new-construction 100,000 gross ft² (9000 gross m²) higher education academic instruction building located in the inland region of Southern California. This project required local heating

hot water and domestic hot water utility production with a tie-in to a campus chilled water system that uses thermal energy storage. As with Case Study 1, the author served as a member of a design‑build team

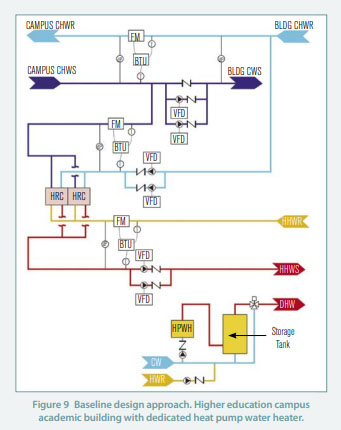

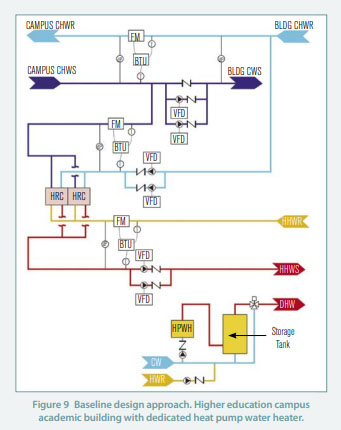

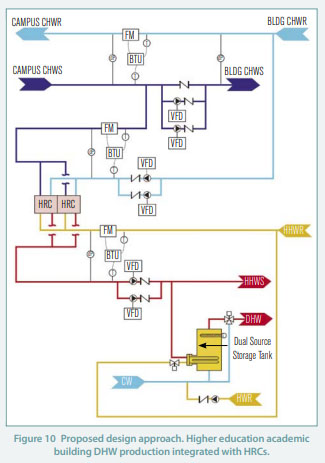

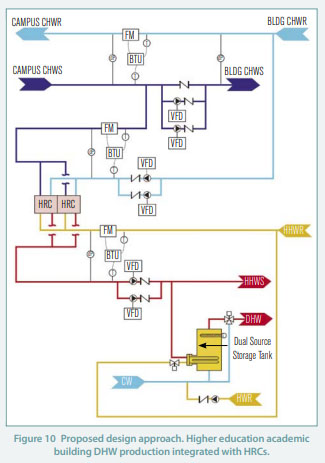

to evaluate various HVAC and plumbing design options to determine the best-value solution based on merit. Figure 9 illustrates the baseline against which our proposed approach, shown in Figure 10, was compared.

The baseline approach was developed according to prescriptive requirements stipulated in the owner’s RFP package. This included the requirement to provide an electric-powered utility plant that incorporates heat pump technology to produce heating hot water and domestic hot water utilities for the proposed building. To provide enhanced value and performance to the owner, our design‑build team proposed, as part of our baseline design approach, using heat-recovery chillers in lieu of heat pumps to reduce load on the campus chilled water infrastructure and improve energy efficiency.

In the baseline approach, heating hot water is produced from a pair of modular heat-recovery

chillers sized to meet building heating demands combined with a tie-in to the campus chilled water infrastructure to accommodate peak cooling demands.

Each heat-recovery chiller module is furnished with a set of integral automated isolation valves that are controlled by a factory controller to modulate output and prevent bypass of chilled and heating

hot water through inactive modules under normal operation. A single air-source heat pump domestic water heater with a remote storage tank is provided to meet the demand for domestic hot water.

The owner’s RFP encouraged design-build teams to consider and propose alternative design solutions based on merit to the project and owner. Our team evaluated design alternatives based on the four goals noted in Case Study 1.

The integrated domestic water heater design approach shown in Figure 10 yielded significant advantages that our design-build team and the owner found desirable. The proposed approach consists of a single dual-source tank-type water heater that uses the HVAC heating hot water utility to preheat the domestic cold water from ~60°F (~15.6°C) to ~110°F (~43.3°C) with auxiliary electric resistance element heaters as the second heat source to lift the water to its storage temperature of 140°F (60°C).

The heat-recovery chillers were initially sized to provide an aggregate heating capacity of 1,307MBtu/h (373kW) based on the selection of two equally sized “60 ton” modules to meet a design heating load of 1,041MBtu/h (305kW) during a design heating condition. This yields an additional 266MBtu/h (78kW) of “spare” capacity that enables consideration of the proposed approach of integrating the domestic hot water production.

First cost

The proposed approach of integrating domestic hot water production with the heat-recovery chillers yielded first cost savings of approximately $45,000 through characteristics similar to those in Case Study 1. In this case, the first cost savings is roughly proportional to the size of the domestic hot water application. Because the domestic hot water load is substantially less for the higher education academic instruction building in this case study than for the medical office building in Case Study 1, the first cost savings is lower. However, the savings is still significant for this application.

Maintenance

As with C, the proposed design approach reduces the anticipated maintenance obligations through elimination of dedicated heat pump components. This benefit is accentuated by the small size of the heat pump system specified in the baseline design approach; elimination of unique equipment maintenance requirements is a benefit that owners with limited operational staff and budget can appreciate.

Energy efficiency

For this case study, the energy efficiency of the proposed design is anticipated to be superior to that of the baseline because the proposed design will typically be in heat-recovery mode during normal operation, producing useful chilled water to back-feed into the campus chilled water loop when there isn’t coincident demand for chilled water in the building. This yields a better COP than a typical air-source heat pump water heater under many operational scenarios (Table 1).

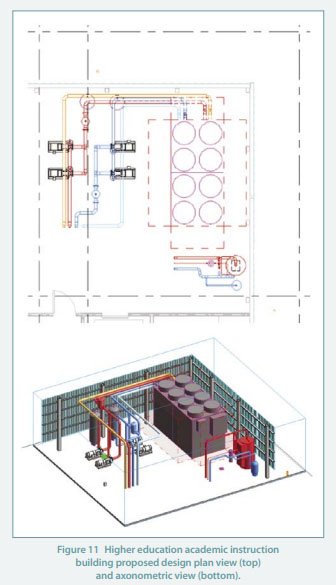

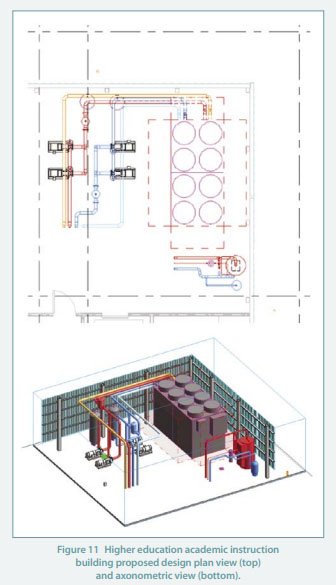

Reduced mechanical room space requirements

The proposed design approach was able to be packaged within a relatively compact configuration (Figure 11). This space savings was made possible by consolidating the separate air-source heat pump water heater and remote storage tank of the baseline approach into a single dual‑source tank-type water heater.

The design team anticipates that the proposed design will require approximately half the space required by the baseline design approach; as the design team performed a detailed physical comparison of a similar baseline design approach in Case Study 1, the baseline design option was not explicitly modeled for this case study.

Conclusion

Total electrification of building utility plants requires careful consideration during execution to achieve a cost-efficient and operationally efficient outcome. Decarbonisation has blurred traditional lines between mechanical and plumbing design practices, requiring knowledge and collaboration from both design practices to determine the best options possible for the application.

Integration of utilities such as domestic hot water, which should be evaluated as rigorously as heating hot water and chilled water production, adds another dimension of complexity to the decision-making process. The author recommends that designers consider integration of some aspect of domestic hot water production into their heat-recovery chiller designs to streamline electrification of building utilities.

This article was originally published in the August 2021 edition of the ASHRAE Journal. It is reprinted with permission.

This article may not be copied and/or distributed electronically or in paper form without permission of ASHRAE.

For more information about the ASHRAE Journal, visit www.ashrae.org

This article appears in Ecolibrium’s Summer 2022-23 edition

View the archive of previous editions

Latest edition

See everything from the latest edition of Ecolibrium, AIRAH’s official journal.