Sound investment

Canberra Grammar School’s new Snow Concert Hall features a subterranean design boasting an innovative ground‑source heat pump system.

Canberra Grammar School (CGS) prides itself on offering holistic education for its students, and catering for individual needs and aspirations.

That means providing opportunities to advance in areas beyond the traditional academic subjects, with exposure to musical education an essential component of this.

Now the school can offer what surely must be one of the best examples of a musical educational facility in the country.

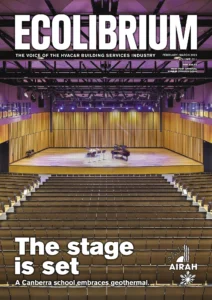

Designed by COX Architecture and built by Construction Control, the project has delivered the 1,400-seat Snow Concert Hall, along with acoustically designed classrooms that double as performance spaces, and 18 musical tuition rooms.

A new student library was also incorporated into the build.

A nod to the past

Architecturally designed to honour the school’s historic buildings, the new auditorium complex is located in the middle of the school. It looks both inward to the heritage quadrangle and outward across the main oval.

It features a new breezeway building and is designed to be transparent, acting as a spacious foyer for the new auditorium and a space for indoor gatherings, functions and exhibitions.

The upper floor accommodates a new student library, linking teaching areas on either side. This replaces the former Senior School Library, which will be redeveloped to accommodate primary school classes.

The Snow Concert Hall is the school’s first purpose-built concert venue. The school’s aim for its new facility was for it to be equivalent in quality to the music program offered.

Using the falling contours of the land, the auditorium is substantially subterranean in design. It includes the central acoustically tuned concert hall. The hall has capacity for more than 1,000 patrons, with a further 400 seats in the elevated balcony providing flexibility for venue use.

The concert hall provides the school with capacity to accommodate the whole of the senior or primary school for assemblies, as well as the ability to hold orchestral, ensemble, bands and choral concerts. It also gives Canberra an additional concert venue for local artists, visiting musicians and orchestras, and community music groups.

The wings of the hall are home to the new Centre for Music. This addition effectively doubles the capacity of the Senior School Music Department, with the new classrooms, rehearsal spaces and musical tuition rooms featuring the latest in recording technology.

Breaking ground

Mechanical services contractor Benmax became engaged early in the project to provide conceptual design advice and constructability oversight to the consulting engineer Norman Disney & Young (NDY). When the preliminary sketch plan design phase was completed, Benmax took over the design responsibility as part of its D&C contract.

The benchmark approach was to service the new building via central plant consisting of two air-cooled chillers and two gas-fired condensing boilers. This was tabled alongside an air-sourced heat pump system to align with the school’s desire to follow the ACT government’s push to phase out natural gas use by 2045.

“Whilst both these systems were investigated for efficiency, viability and ultimately cost, it became apparent that the availability of space for an exposed central plant was very limited on the site,” says Benmax senior engineer Christopher Ward, M.AIRAH.

Two locations were identified for the plant. But with both of these located more than 125m from the new building, all electrical provision, natural gas connection, as well as flow and return chilled and heating hot water pipework would need to be trenched and reticulated between the two sites.

Because both benchmark systems were considered cost-prohibitive and with limited future development on the campus, a ground-source heat pump (GSHP) solution was evaluated.

“The option of a ground-source heat pump had originally been on the table early in the preliminary design stages of the project, as the new building is located adjacent to three large sport fields,” Ward explains. “It was discounted, though, due to the capital cost required to establish the heat-rejection loop, as well as the anticipated damage and downtime to the playing fields.”

Ward says the system was also hindered at the time by the common myths that go “hand-in-hand” with GSHP systems. Some of these included that the technology has poor heat conductance due to clay soils, potential difficulties and delays associated with drilling through local rock layers, and the supposed failure of a similar system serving a nearby building.

“While all not true,” Ward says, “these myths initially pushed the system into the too- hard basket.”

Changing climate

By 2019, the understanding that the cost of installing a remote central plant was going to be cost-prohibitive took hold, and GSHP system specialist GeoExchange Australia was engaged.

“Canberra has a strong history with GSHP systems – although an often misunderstood one,” says GeoExchange Australia managing director Yale Carden.

“While there have been many successful projects, there seems to have been some odd anecdotal stories about the technology not working or being difficult that are just not true.”

The first task for Carden was to debunk the myths associated with GSHP systems. This was easily achieved by demonstrating several successfully operating systems. GeoExchange Australia then guided the design team through the steps required to validate the viability of the ground heat exchanger (GHX). Energy modelling was also conducted to demonstrate the payback period depending on system size and use.

“On the basis of positive outcomes,” Carden says, “we then installed a test borehole, conducted an in-situ thermal conductivity test and then progressed into detailed design and documentation.”

The test yielded a mean earth temperature of 17.7˚C across the depth of the borehole.

The adoption of a GSHP system also advantaged the overall building design by eliminating the need for a large externally ventilated plant room.

“The ‘plant room’ was now located beneath the level of the adjacent playing fields as well as in the basement of the new building,” says Carden.

Ground source

The heating and cooling needs of the building are provided by six modular polyvalent four-pipe water/ground-sourced heat pump units located in the basement plant room about 12m below ground level.

Based on a distribution system familiar to the industry, the water/ground-sourced heat pumps are connected in a reverse-return configuration with the GHX, or ground loop. Using an extended-range refrigerant cycle, each heat pump is able to absorb or reject energy from/to the GHX to produce 55˚C heating and 5˚C cooling water simultaneously.

“As both heating and cooling water is produced simultaneously, energy is automatically transferred from the cooling loop to the heating loop,” says Ward, “thus minimising the total energy drawn from or rejected to the GHX.”

Because the GSHP system absorbs or rejects heat via its interaction with the earth, there is no requirement for traditional above-ground heat rejection equipment. This eliminated the traditional moisture plumes associated with cooling towers, the combustion gas flues associated with gas-fired boilers, and the noise of air-cooled equipment.

“All these factors were critical given the heritage status of the adjacent school buildings,” says Ward, “while also maintaining the opulent nature of the school’s activity areas.”

The GHX is located on the upper sports field and within 200m of the plant room. It consists of 84 boreholes to a depth of 100m, configured in a grid pattern on a 6–8m spacing. A field manifold is located on the edge of the oval and a pair of flow/return pipes connect to the plantroom.

Over 20km of Polyethylene pipework, ranging in size from 32mm to 200m, has been installed to support the GSHP system. This pipework is anticipated to have a lifecycle of more than 200 years.

Because they’re located in the building’s basement, the future replacement of the heat pump units (once at the end of their serviceable life) had to be considered carefully. The units used on this project were selected for not only their capacity and efficiency but also their size, with each unit capable of fitting within the lift car that extends to the basement level.

As both heating and cooling water is produced simultaneously, energy is automatically transferred from the cooling loop to the heating loop.

Operating as a modular group to deliver the >500kW of cooling and heating capacity requirement to the building, each unit can supply approximately 85kW at its peak. This enables significant levels of turndown when the building is at minimal load, further improving efficiency during low-load periods.

Internal conditions

Individual air-handling units (AHUs) serve the auditorium main floor, stage and bleacher seating zones. Each is configured for underfloor air displacement (UFAD), utilising CO2 monitoring to minimise energy consumption while maintaining a high standard of indoor air quality.

The AHUs serving the auditorium and stage areas also incorporate dehumidification control; they use split cooling coils and coil bypass dampers to limit humidity levels within the space.

An individual AHU that’s located within the basement plant room serves the lower-ground foyer area. It is sized to accommodate the varying uses of this space, whether that be traditional educational environment, formal foyer or the Snow Concert Hall itself. This unit is equipped with an outside air economy cycle to enable an increase in the supply of outside air under appropriate ambient conditions.

The lower-ground rehearsal rooms, classrooms, corridors and auditorium stage corridors are served by localised ceiling-mounted air-handling plant. Each AHU is connected to outside air ductwork as well as to the central CHW and HHW systems. The same system design serves the quadrangle lobby and library areas.

“Units other than those serving corridor and circulation spaces utilise CO2 monitoring to minimise energy consumption whilst maintaining a high standard of indoor air quality,” says Ward.

The mechanical systems associated with the auditorium, rehearsal spaces and classrooms include extensive acoustic treatment in accordance with the acoustic requirements of each space.

“As a point of interest, no smoke exhaust systems were required for the building, with typical NCC requirements being engineered out by the fire services engineer, LIT Consulting,” adds Ward.

“In the event of a fire alarm, all mechanical air-handling plant will shut down to minimise the spread of smoke while the occupants safely evacuate.”

A modular, prefabrication approach was taken to the mechanical services construction and installation. This was due to the concrete building structure being poured around the main basement plant room 12m below ground.

Ward says, this means it was critical that central plant as well as the four main AHUs were installed quickly and effectively. Once the structural concrete slab above the plant room was poured no further access for heavy equipment would be possible.

“Benmax prefabricated all of the major plant across seven semi-truck-sized skids at our prefabrication facilities in Queanbeyan,” he says. “This ensured all of the equipment would fit together, with minimal tolerance, once transported to site.”

Using this technique, the full plant room was installed within eight hours, allowing the builder to start framing out the concrete slab above the next day.

Ideal conditions

The Canberra Grammar School’s new auditorium project was considered to be an ideal candidate for ground-source heat pumps for a number of reasons – the first being the climate.

“Canberra’s climate requires both heating and cooling, meaning longer operating times to assist with the business case,” says GeoExchange Australia’s Yale Carden, M.AIRAH. “This also provides a better thermal balance in the ground heat exchanger – that is, we extract as much heat from the ground in winter as we reject in summer – allowing for a more efficient and better performing system.”

Other advantages include the long-term nature of the asset owner, the project economics associated with energy savings and construction cost savings, the ACT gas phase-out and the possible future connection of other buildings.

The sound of silence

Significant attention was given to the acoustic treatment of the HVAC systems serving the Snow Concert Hall and lower ground classrooms and rehearsal spaces, led by the project’s acoustics consultant.

“An important factor in controlling noise from HVAC systems is the limitation of air velocity through the duct and air terminals,” says Simon Connolly of Marshall Day Acoustics.

This work was carried out early in the design phase, allowing the provision in design of maximum allowable air velocities for the supply and return-air duct according to the proximity of the duct to the occupied area.

This approach enabled sufficient spatial allowances to be made for their required duct sizes at a sufficiently early stage in the design phase.

“Once the required attenuation (sound reduction) had been calculated, early dimensioning of the necessary attenuators was carried out in order to allow coordination with the spatial limitations,” says Connolly. “The attenuations required dimensioning and specification such that airflow generated by the attenuators themselves did not add to fan-generated internal noise levels.”

Specific acoustic construction detail around duct penetrations also formed the necessary acoustic separation between the plant room and plenum below the concert hall seating. The specific selection of supply-air diffusers to manage airflow noise in the concert hall was also required to maintain the required noise criteria.

“The plant room itself was specified with acoustic insulation in order to reduce internal noise and spill to other adjacent spaces,” Connolly says, “while duct treatment and attenuators to exhaust air and intake air minimised noise spill to the outdoor areas near the lobby entrance.”

In other spaces, fan coil units (FCUs) were located outside to minimise the acoustic treatment required for case-radiated noise. FCU supply and return-air alignments were also optimised to allow for a favourable supply and return-air duct path in and out of the music rooms. Attenuators were selected to achieve the required noise criteria.

To minimise noise ingress from outside the music rooms during school activities, attenuators were specified for the relief air path from the classrooms.

Gala opening

With the construction schedule impacted by COVID-19 lockdowns, border restrictions and Canberra’s wettest year on record, the project suffered a number of unavoidable delays before reaching practical completion in mid-2022.

A gala concert to celebrate the official opening of the Snow Concert Hall and the new CGS Music Department and Library was held in late August 2022.

Performing alongside Canberra Grammar School students were talented alumni of the school, including acclaimed cellist Christopher Pidcock, organist Marko Sever, and vocalists Chelsea Bonanno and Liam Budge.

Ground-source heat pump lessons

GeoExchange Australia managing director Yale Carden, M.AIRAH, shares some of the lessons to come from the installation of the ground source heat pump system at Canberra Grammar School.

“The importance of early feasibility in identifying whether a GSHP system is a good fit for the project cannot be underestimated,” he says.

“This regularly means more than just energy savings. It is about integrating the system into the building, or the site itself. In this instance, it was architectural design and heritage considerations, as they related to the plant room that drove the solution.”

And he offers one other nugget of advice:

“Minimise drilling during La Niña winters in Canberra!”

Project at a glance

The personal

Client: Canberra Grammar School

Project manager: Construction Control

Acoustic consultant: Marshall Day Acoustics

Architect: COX

Fire safety engineer: Lit Consulting

Geo consultant: GeoExchange Australia

GHX contractor: Diona Geothermal

Mechanical services design and construct: Benmax

The equipment

AHU/FCUs: Johnson Controls/York

Attenuators: IAC Acoustics

BMS: Control and Electric/Siemens

Diffusers: Holyoake

Fans: Fantech

Heat exchangers: Heat Exchangers WA/Kelvion

GSHPs: Stiebel Eltron

Sensors/valves: Siemens

Thermal Storage Tanks: Stiebel Eltron

Pumps: QMAX/Grundfos

Split systems: Mitsubishi Electric

Ductwork: Ductrite

Geothermal bores and pipework: Calibre/Diona

This article appears in Ecolibrium’s February-March 2023 edition

View the archive of previous editions

Latest edition

See everything from the latest edition of Ecolibrium, AIRAH’s official journal.