Artificial Intelligence (AI) applications in the building and property industry

Abstract

Artificial intelligence (AI) is an area of computer science that emphasises the creation of intelligent agents, which are systems that can learn and act autonomously. AI deals with the question of how to create computers that are capable of intelligent behaviour.

There is no doubt that artificial intelligence is rapidly evolving. We are seeing milestones reached in areas such as self-driving cars, facial recognition, text generators, text-to-image generators, and more. But what does the future hold for AI? And while AI has already made significant advancements in many industries, there’s still great potential for what it can do in the future – particularly in the realm of HVAC.

AI has the potential to revolutionise the way buildings are managed and operated. By incorporating AI into HVAC systems, building owners and operators can improve energy efficiency, reduce costs, and enhance indoor air quality. AI-based systems can also adapt to changing weather conditions and occupancy patterns, providing greater flexibility and control over the building’s HVAC system. Additionally, AI-based systems can optimise energy use by monitoring energy consumption patterns and adjusting HVAC settings accordingly. This can lead to significant cost savings over time, especially for large commercial buildings that consume a significant amount of energy.

Introduction

Buildings contribute approximately 40% of the total global energy consumption [1], and almost 40% of this goes towards heating, ventilation, and air conditioning (HVAC) systems [2]. Clearly, the development and implementation of efficient building energy control systems is essential for economic and environmental sustainability.[3]

Managing, optimising, maintaining, and commissioning HVAC systems can be a challenging task due to their size and complexity. These systems play a crucial role in regulating temperature, ventilation, and air conditioning in buildings to ensure a comfortable indoor environment. Nevertheless, because of their often complex nature, HVAC systems need regular monitoring and maintenance. In particular, many HVAC systems are not properly sized, maintained, or commissioned, which leads to wasted energy and poor indoor air quality.

This is where AI can come in. In the future, AI will become more involved in the operation of HVAC systems. In fact, HVAC systems may even be able to autonomously manage the entire system, by for example, adjusting the temperature and humidity, noise, carbon dioxide (CO2), and light intensity according to the needs of the occupants, and even detect and diagnose problems in the system. For example, a network of smart sensors, mobility data, and cameras can be used to detect when parts need to be replaced or repaired.

Model-based control and rule-based control are two common approaches to controlling HVAC systems. Model-based control, also known as model predictive control (MPC), uses mathematical models of the building and HVAC system to predict the behaviour of the system and optimise its operation. MPC algorithms use real-time sensor data to adjust the system’s set points and operating parameters, based on the predicted behaviour of the system.

This approach can be particularly effective in complex systems where multiple variables need to be considered to optimise performance and energy efficiency. To implement MPC, we need to develop a mathematical model of HVAC system, which may involve gathering data on its behaviour and using that data to build a predictive model. Then, we need to develop an optimisation algorithm to determine the optimal control inputs for the system based in the current state and desired outcome.

Rule-based control (RBC), on the other hand, uses a set of predefined rules to control the HVAC system. These rules are typically based on a combination of factors, such as occupancy, time of day, weather, and other environmental factors. For example, an RBC system might turn off the HVAC system during times of low occupancy, or adjust temperature set points based on the outside temperature. While rule-based control is simpler than model-based control, it may not be as effective in optimising energy efficiency or responding to changes in the system.

To implement RBC, we need to define a set of rules that dictate how the system should respond to different inputs. These rules could be based on simple if-then statements, or they could be more complex, involving multiple conditions and actions. Once the rules are defined, you would need to implement them in software or hardware to control the HVAC system.

Both MBC and RBC have their advantages and disadvantages, and the choice between the two depends on the specific application and requirements of the system. Some systems may benefit from a combination of both approaches, using RBC for simpler tasks and MBC for more complex optimisation tasks.

MBCs are more accurate than RBCs, but they require more computational resources. RBCs are less accurate than MBCs, but they can be implemented with less computational resources. Let us dive into details to understand both systems.

Model–based predictive control (MPC)

Model-based predictive control is a powerful control strategy used in many industries to optimise complex systems. It is used in chemical process control and automotive control. MPC is extremely useful in applications where there are multiple objectives that need to be considered such as temperature, humidity, occupancy, flow rate, pressure, as well as immeasurable variables such as internal states of the system. By considering these variables, MPC can optimise the system performance across multiple objectives such as energy efficiency, safety, and product quality.

The basic idea behind MPC is to use a mathematical model of the system to predict how it will behave in the future, and then optimise the control inputs to achieve a desired outcome. It involves solving an optimisation problem at each time step, based on the current state of the system and the desired objective.

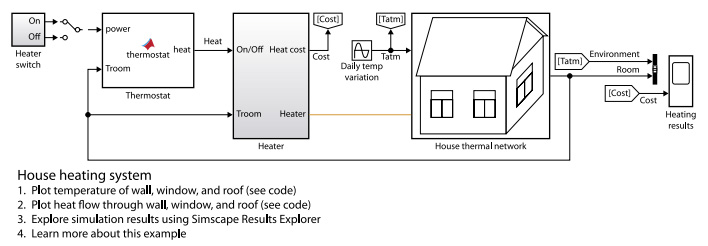

This model can be based on first principles, such as the laws of physics. The model should be validated against experimental data to ensure that it accurately captures the system behaviour. Figure 1 shows the house heating system model in a simulation.

Several studies suggest that MPC is an effective method to improve building system performance. However, several practical problems of the two model types are seldom discussed. (1) First-principle-based models are suitable for single-zone and simple-geometry buildings, but are difficult to apply to real buildings, which typically have multiple zones and irregular geometric shapes. (2) The linear-identified models often require plenty of sensor data both at the system component level and in the indoor environment, which can have high temporal and financial cost. (3) Developing the two models requires high-level mathematical skills, which may not be a viable solution for daily building operation.[5]

Once a mathematical model is developed, the next step is to define the control objectives. This might be maintaining desired temperature set-point, minimising energy consumption, and ensuring occupant comfort. For example, the AI-Based Occupant-Centric HVAC Control System for Multi-Zone Commercial Buildings’ research objective is to devise an HVAC control mechanism in a multi-zone commercial building that is centered around the occupants’ needs and to utilise AI technology to achieve this.[3]

Utilising sensors to measure temperature and airflow, the HVAC system uses these measurements to update a mathematical model of the HVAC system. The mathematical model might consider factors such as the capacity of the HVAC system, the building’s insulation, and the external weather conditions.

Based on this model, the MPC algorithm can predict the future temperature and airflow in each room, and generate optimal control actions to achieve the desired temperature set-points while minimising energy consumption. For example, the MPC algorithm might adjust the set-point of the HVAC system, adjust the fan speed, or adjust the opening of the dampers in each room to achieve the desired temperature set-points while minimising energy consumption.

Once the prediction model is developed, the MPC algorithm can be used to generate optimal control actions that will achieve the control objectives over the specified time horizon. The MPC algorithm optimises the control actions by taking into account the current state of the system, the predicted behavior of the system, and the control objectives.

If the prediction model shows that the temperature in a certain room is likely to rise above the desired set-point in the next hour, the MPC algorithm might generate an optimal control action that involves increasing the airflow to that room to cool it down.

If the prediction model shows that the outdoor temperature is likely to drop significantly in the next few hours, the MPC algorithm might generate an optimal control action that involves adjusting the set-point of the HVAC system to save energy while maintaining a comfortable indoor temperature. Thus, optimal control actions have been generated.

The last step of model-based predictive control is to monitor the system and update the model as needed. The model must be updated regularly to ensure that it accurately reflects the behavior of the system. This is because changes in the system over time, such as the addition of new equipment or changes in occupancy, can affect the system behavior and invalidate the model. In order to update the model, data from the system must be collected and analysed.

Rule-based predictive control (RBPC)

Rule-based predictive control (RBPC) is a type of control algorithm used in engineering systems that combines the simplicity of rule-based control with the predictive power of model-based control. RBPC is a popular approach for controlling complex systems where the behavior is difficult to predict, and where the traditional model-based control methods may not be effective.

In RBPC, a set of rules are defined by experts or engineers, which specify the desired control action based on the current state of the system. These rules are then combined logically to determine the appropriate control action. The rules may be based on simple if-then statements or more complex logical constructs, such as fuzzy logic or neural networks.

Again, the first step is to define the control objectives. It could be minimising energy consumption, or maintaining a comfortable indoor environment. Once objectives are defined, rules need to be developed. These rules may specify:

- If the indoor temperature is above the desired set- point, turn on the air conditioning

- If the indoor temperature is below the desired set-point, turn on the heating

- If the outdoor temperature is below a certain threshold, turn on the heating to preheat the indoor space

- If the outdoor temperature is above a certain threshold, use natural ventilation to cool the indoor space

- If occupancy level in a room is low, reduce the airflow rate to save energy.

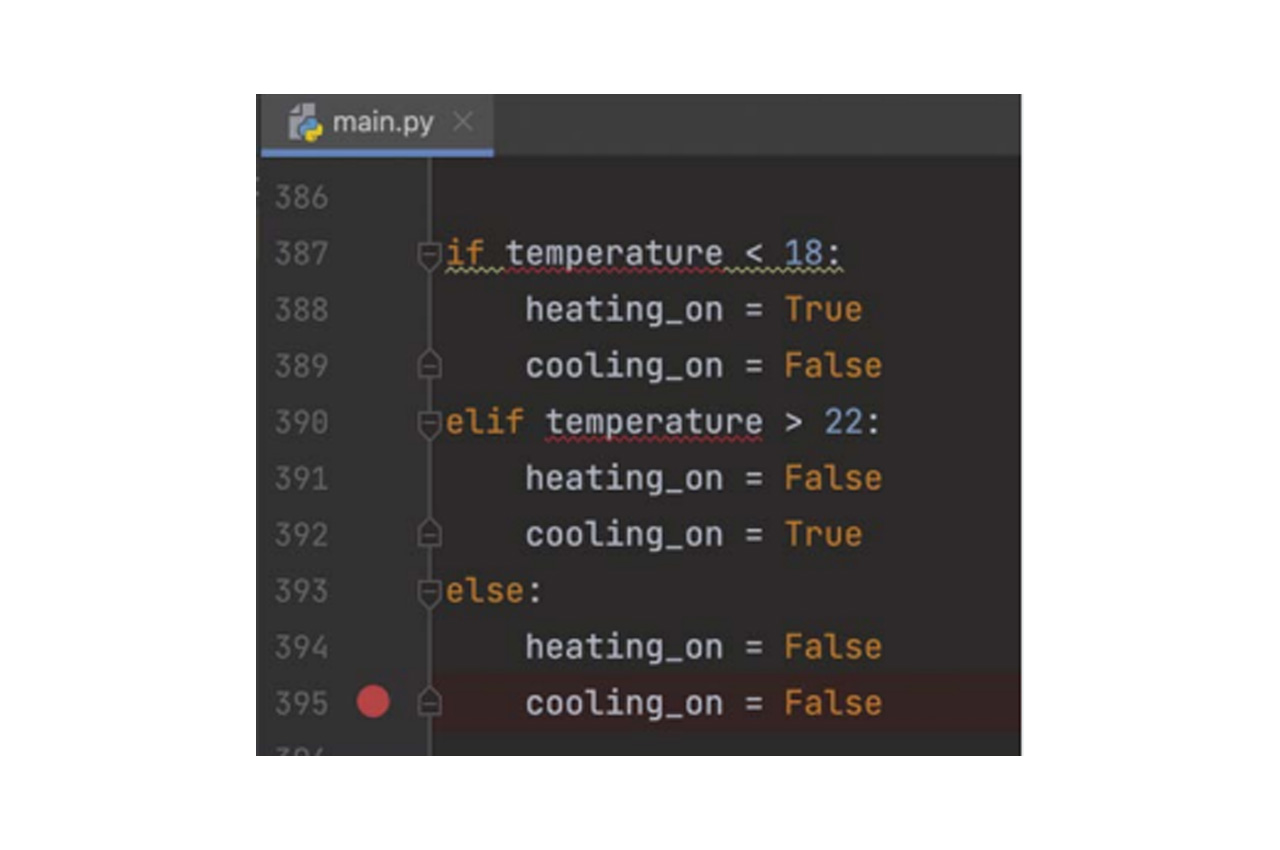

These rules can be refined and adjusted over time based on feedback from the occupants and performance of the system. To implement these rules, different programming languages could be used such as python or C++.

In this code, the temperature value is checked against the temperature range defined in the rules using a series of if-else statements. If the temperature is below 18°C, the heating system is turned on and the cooling system is turned off. If the temperature is above 22°C, the heating system is turned off and the cooling system is turned on. Otherwise, both systems are turned off. Once the rules have been defined and implemented in code, they can be integrated into a control system. The input values are read from sensors, and the output values are used to control the system’s actuators.

The performance of the HVAC system must be monitored to ensure that it is meeting the control objectives. This can be done using sensors and data acquisition systems, as in the model-based approach. The data can be analysed to identify areas where the system performance can be improved.

In summary, rule-based predictive control involves developing a set of control rules based on the control objectives and the characteristics of the system. The rules are implemented using a control strategy and refined over time based on feedback from the occupants and the system performance.

This approach can be less computationally intensive than model-based predictive control and can be effective in simple HVAC systems. However, it may not be as flexible or as accurate as model-based control in more complex systems.

Conclusion

In conclusion, AI is going to play a crucial role in the HVAC industry’s future. The main ways AI will likely be deployed are through predictive maintenance, energy management, fault detection and diagnosis. By harnessing the power of AI, HVAC contracting companies will be able to improve efficiency, reduce costs, and provide a better overall experience for customers.

With the continued development of AI technology, HVAC systems are likely to become more efficient, reliable, and cost-effective. Recent advances in AI can improve the management of HVAC systems. AI-based HVAC controls can automatically calibrate HVAC systems and optimise their operation to save energy and improve indoor air quality.

Model-based control relies on mathematical models of the system to predict its behavior and generate optimal control actions. Although it requires a high level of expertise in mathematical modelling and control theory, it provides excellent control performance and is suitable for critical applications where precision is important.

Rule-based control, on the other hand, is a more practical and flexible approach that relies on a set of predefined rules defined by domain experts. It can be easily implemented using programming languages and is suitable for less critical applications where intuitive and flexible control is important.

In some cases, a combination of model-based and rule-based control can be used to achieve optimal control performance and flexibility.

Ultimately, the choice between the two approaches depends on the specific requirements and constraints of the control system application. Compared to the baseline rule-based control system, EPMPC demonstrates a 28.9% energy reduction in a one-week simulation in the heating season and 2.7% energy reduction in one-week simulation in the cooling season. [6]

References

[1] IEA (International Energy Agency). Energy Efficiency: Buildings. 2019 (Accessed on October 11, 2022).

[2] Yang, L.; Yan, H.; Lam, J.C. Thermal Comfort and Building Energy Consumption Implications—A Review. Appl. Energy 2014, 115, 164–173. [Google Scholar] [CrossRef]

[3] Artificial Intelligence (AI)-Based Occupant-Centric Heating Ventilation and Air Conditioning (HVAC) Control System for Multi-Zone Commercial Buildings- Alperen Yayla, Cobra Sultan Swierczewska, Mahmut Kaya, Bahadir Karaca, Yusuf Arayici, Yunus Emre Ayozen, Out Behzat Tokdemir

[4] MATLAB house Heating System R2023a

[5] Energyplus model-based predictive control (EPMPC) by using MATLAB/Simulink and MLE– Jie Zhao, Khee Poh Lam, B Erik Ydstie

[6] EnergyPlus model-based predictive control within design–build–operate energy information modelling infrastructure- Jie Zhao, Khee Poh Lam, B Erik Ydstie, Omer Karaguzel

This article appears in Ecolibrium’s June-July 2023 edition

View the archive of previous editions

Latest edition

See everything from the latest edition of Ecolibrium, AIRAH’s official journal.