Innovative space cooling and heating using an R744 heat pump: a comparative study

This paper by Alemu Tiruneh Alemu, M.AIRAH, and Julian Hudson, M.AIRAH, explores sustainable HVAC solutions by focusing on electrifying heating with heat pumps and operational cooling and heating efficiencies.

Abstract

HVAC systems in non-residential buildings are responsible for significant electricity consumption and carbon emissions. This paper explores sustainable HVAC solutions with by focusing on electrifying heating with heat pumps and operational cooling and heating efficiencies. The study finds that R744 (CO2) systems, particularly with direct CO2 DX cooling coils and CO2 desuperheater heating coils in air handling units and fan coil units, outperform hot water and chilled water heat pumps.

The direct air heating CO2 heat pump is 28–65 per cent more efficient than the R454C heat pump for all heat pump source temperature ranges. The CO2 DX cooling system is 5.5–15.6 per cent more efficient than the R454B air-cooled chiller at the ambient air temperature ranges considered. These findings demonstrate the CO2 direct air heating and cooling system’s superior efficiency for both heating and cooling in supermarket HVAC applications. This outcome could also apply to other non-residential buildings.

Introduction

Non-residential buildings account for approximately 24 per cent of total electricity consumption and 10 per cent of overall carbon emissions in Australia1. A significant portion of this energy usage and greenhouse gas contribution stems from the operation of HVAC systems. Selecting the right sustainable HVAC solution is crucial for minimising electricity usage, reducing greenhouse gas emissions and ultimately achieving decarbonisation goals. A key aspect of this transition is the electrification of heating systems, which involves replacing gas boilers for heating with more efficient electric heat pumps. This shift plays a significant role in moving toward a more energy-efficient, low-carbon future.

The use of natural or low-global warming potential (GWP) refrigerant heat pumps helps to decarbonise operations in buildings. Most importantly, how the systems are configured to provide the intended energy services determines their impact on operational energy efficiency and greenhouse gas emissions.

HFO (hydrofluoroolefin) and HFO/HFC (hydrofluorocarbon) blend chillers and heat pumps are gaining popularity as low-GWP, environmentally friendly alternatives. However, environmentalists and researchers have raised concerns about the potential impact of HFO refrigerants on the environment, in particular aquatic pollution. A recent study has shown a significant increase in the amount of trifluoroacetic acid (TFA) present in the environment since the introduction of HFO-1234yf as a replacement for R-134a2. HFOs are also listed as PFAS (perfluoroalkyl and polyfluoroalkyl substances) or “forever chemicals”, which are under intense scrutiny, with possible bans being considered in Europe3.

R290 – also known as propane – is a natural refrigerant that is gaining attention for supermarket heating and cooling in chillers and heat pumps. R290 has a GWP of 3, making it a sustainable, climate-friendly refrigerant option for HVAC applications. R290 is classified as highly flammable and non-toxic, with an ASHRAE safety class of A3. This results in limited allowance of refrigerant charge in a system and constraints that allow R290 refrigerant to be used only in a packaged system with secondary heat transfer fluids, such as R290 chillers and hot water heat pumps in supermarket applications. Direct application of A3 refrigerants such as R290 for DX cooling and air heating into air handling units is not practical because of their very low charge.

CO2 is rapidly gaining traction as a more environmentally friendly refrigerant. Unlike HFCs, which have high GWPs, CO2 has a GWP of 1, making it an excellent alternative for reducing the climate impact of refrigeration and HVAC. CO2 is classified as a non-flammable and non-toxic refrigerant, with an ASHRAE safety class of A1, further enhancing its appeal for use in commercial applications. In addition to its environmental advantages, CO2 features superior heat transfer properties compared to many other refrigerants, thanks to its high density and operating pressures, meaning it performs well in airside heat exchangers such as evaporators and condensers/gas coolers.

In the authors’ view, the limited use of CO2 heat pumps for HVAC applications – despite the success of CO2 refrigeration systems – stems from concerns over lower operational efficiency. Specifically, CO2 heat pumps for heating and cooling are thought to be less efficient in comparison to HFO and HFO/HFC blend systems, particularly when it comes to producing chilled or hot water. The operational efficiency of a CO2 heat pump is significantly influenced by the return water temperature and the target supply water temperature for heating. To maximise efficiency, the return water temperature should remain below 40°C, as lower heat sink temperatures lead to better coefficient of performance (COP) in heating applications.

This paper explores the heating and cooling COPs of different heat pump systems for heating and cooling supermarket trading floors. A supermarket HVAC application was chosen for this comparison study, as the operational data for the direct CO2 heating & cooling option is derived from actual data. However, the outcome could also apply to other non-residential buildings.

The three heat pump heating options are: hot water CO2 heat pumps, HFO/HFC-based hot water heat pumps, and direct air heating CO2 heat pumps. R290 hot water heat pumps are not considered in this study as their performance is similar to hot water heat pumps using HFO/HFC refrigerants (such as R454C). Gas-fired and in-line electric heating systems are excluded from this comparison, as gas systems are expected to be phased out in favour of decarbonised alternatives, while electric heating is generally considered the least efficient sustainable heating option.

The three cooling systems options are: CO2 chilled water system, HFC/HFO-based chilled water system, and CO2 heat pump with DX coils used in AHUs (air handling units) and FCUs (fan coil units). R290 chillers are not explicitly included in this study as they have similar performance to chillers using HFC/HFO refrigerants (such as R454B); the performance outcome for the HFC/HFO chillers presented here can represent that of R290 chillers.

By examining these alternative HVAC systems, the paper aims to provide valuable insights into the future of sustainable HVAC technologies in supermarkets and commercial buildings.

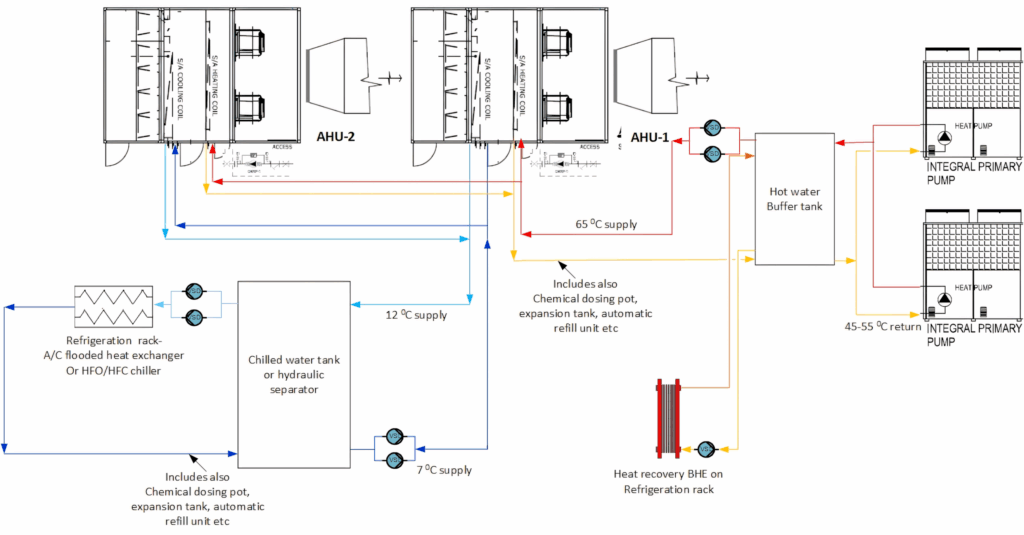

Figure 1: Typical configuration outlines of an HVAC system in a major supermarket, using chilled water and hot water loop.

Recent trends for integrated HVAC systems in major supermarkets

A typical HVAC system configuration in many new major supermarkets is outlined in Figure 1. Cooling and heating demands in AHUs and FCUs are met by chilled water coils and hot water coils. A small amount of heat is also recovered from the refrigeration system via the hot water loop.

Chilled water is either produced by a dedicated chiller or flooded heat exchanger integrated into the main refrigeration system. The hot water is produced by air-source hot water heat pumps.

Proposed HVAC system configuration in major supermarkets

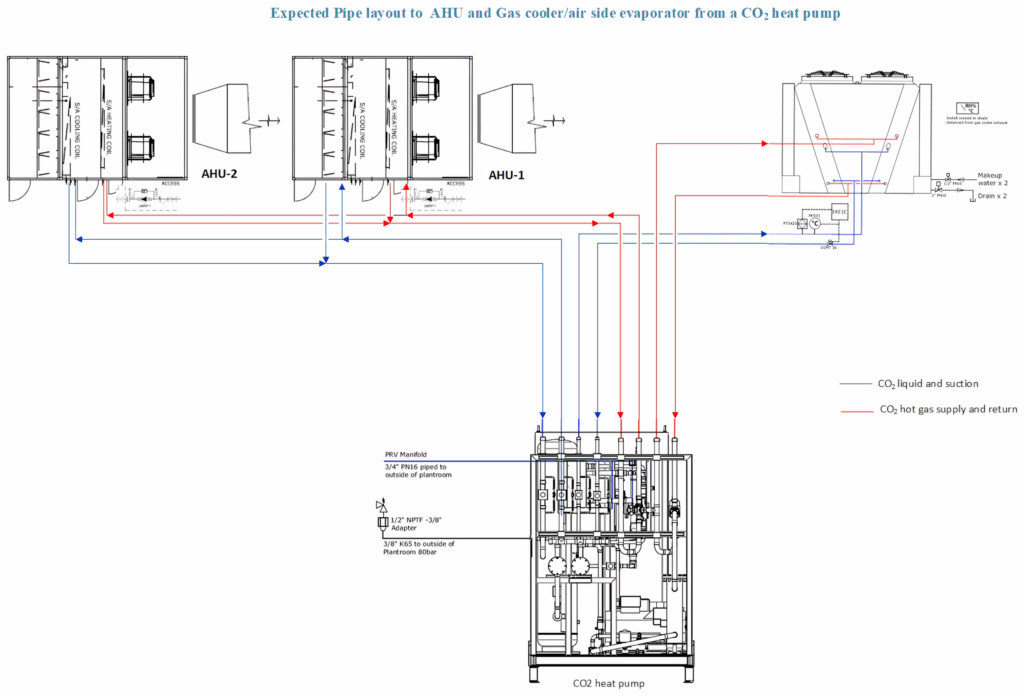

Figure 2 presents an outline of the proposed CO2 HVAC system for major supermarkets. The cooling and heating demand in the AHUs and FCUs are met by direct CO2 DX air cooling coils and CO2 desuperheater air heating coils. This approach also allows for simultaneous cooling and heating (dehumidification and reheat) in any of the AHUs or FCUs. The integrated gas cooler and airside evaporator takes care of the balance of the loads. This approach eliminates the need for chilled water and hot water hydraulic loops for space heating and cooling. It is important to note that this comparative study does not account for the additional benefit of simultaneous heating and cooling provided by this configuration.

Figure 2: HVAC system configuration outlines for major supermarket application using direct CO2 cooling and heating coils into AHUs and FCUs.

Predictive tools and assumptions used for the comparison

The performance of the compressors in different heat pumps used in this comparative study is predicted using commercially available selection and sizing software5. Air-side evaporators and adiabatic gas coolers/condensers are assumed for all systems under consideration.

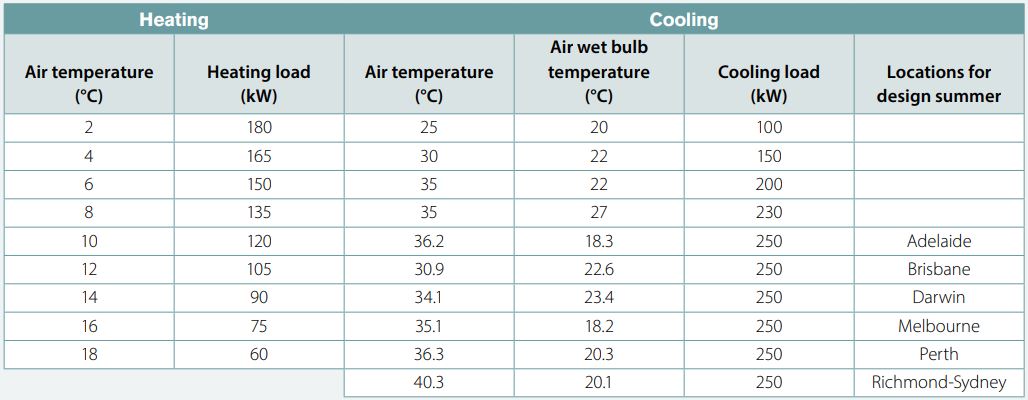

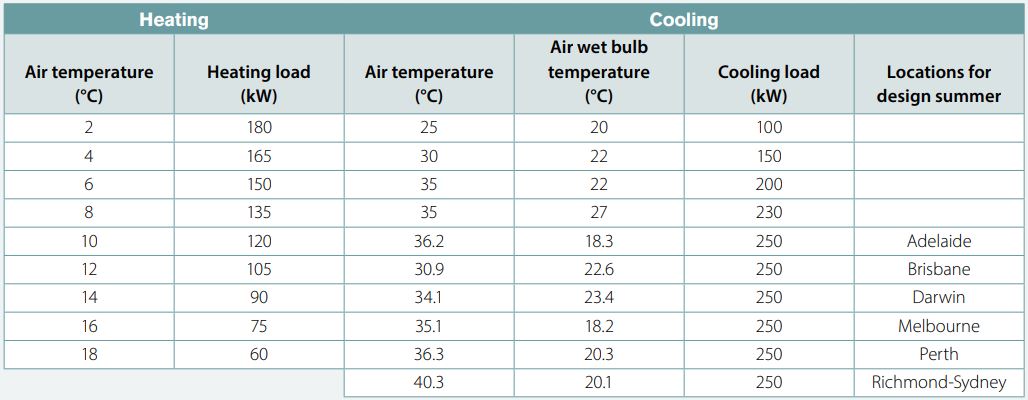

The heating load profile is mainly dependent on ambient air temperature. Table 1 provides the heating load profile with ambient temperature used for comparing the performance of systems. The winter design air temperature for many regions in Australia is above 2oC6.

The cooling profile is highly dependent on ambient air temperature and humidity, as well as occupancy. This comparison study aims to show cooling performance for possible ambient air conditions in different parts of Australia. Summer design conditions for six major cities are also included5 (Table 1).

Table 1. Ambient air temperature range and cooling and heating loads used for comparison study

Heating performance

Three scenarios are considered for comparing heating performance:

- Heating is served by a low-GWP refrigerant air-source heat pump and a hot water hydraulic loop. The hot water is heated from 45oC to 65oC by the heat pump, a typical arrangement in major supermarkets. The refrigerant selected for this comparison study is R454C. R454C is a low-GWP HFO refrigerant with a GWP of 148, which is a close match to R22-based technology, with an ASHRAE safety class of A2L.

- Heating is served by an air-source transcritical CO2 heat pump and a hot water hydraulic loop. The hot water is heated from 45oC to 65oC by the heat pump. An approach temperature difference of 2oC is assumed, such that the expected gas cooler outlet temperature from the hot water heat exchanger will be 47oC.

- Heating is served by an air-source transcritical CO2 heat pump using direct supercritical CO2 for heating in the AHUs and FCUs. Using direct supercritical CO2 in the air distribution system helps to get a low gas cooler outlet temperature from the heating coils, as the coil-on temperature rarely exceeds 22oC. During the heating season, building heating demand is expected to be met if the coil-on temperature of the AHUs and FCUs exceeds 22oC. The gas cooler outlet temperature of 25oC (3oC approach temperature difference between the coil-on air temperature and CO2 gas outlet temperature) is assumed, which is achievable within the allowable pressure drop in the heating coils.

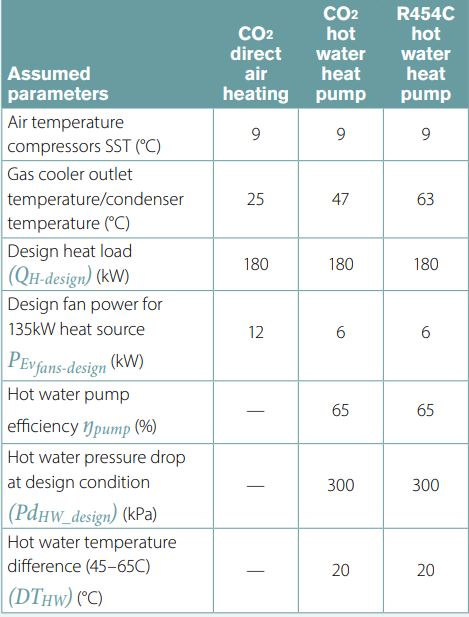

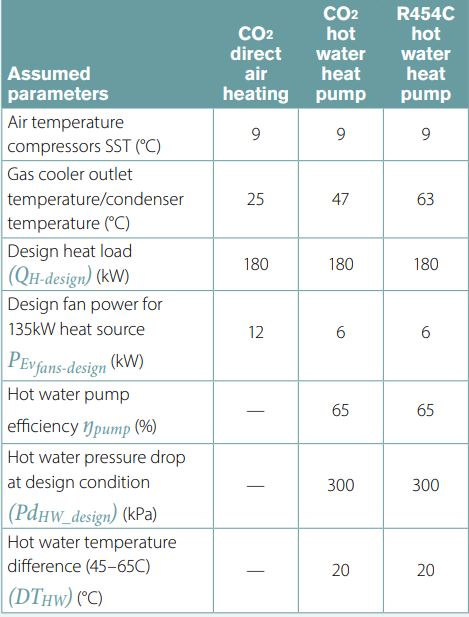

Table 2 provides assumptions for heating performance prediction. In the case of heating, a temperature difference of 8oC between evaporator temperature and ambient air temperature is assumed. Another 1oC is considered for pressure loss in the liquid and suction line, i.e. the temperature difference between the compressors’ saturated suction temperature (SST) and the ambient air temperature is assumed to be 9oC for all three cases, even though the heat transfer effectiveness for CO2 evaporators is expected to be superior and R454C has a significant temperature glide during evaporation.

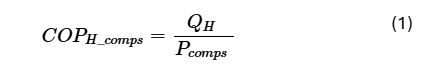

Equation (1) shows the function for compressors’ heating COP (COPH_comps)

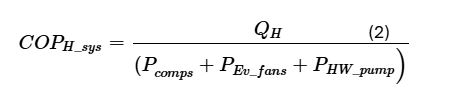

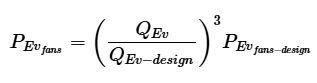

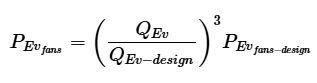

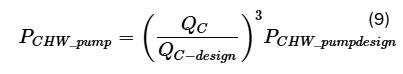

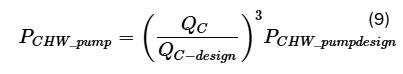

Where QH is heating load in kW and Pcomps is the compressors’ required power input in kW. The heating system COP (COPH_sys) is defined as the ratio of the heating load (QH and the sum of power inputs to the compressors (Pcomps), air‑side evaporator fans (PEv_fans) and hot water pump (PHW_pump) if any (see Equation 2).

An eight-fan integrated air-side evaporator/gas cooler is assumed for the direct CO2 heat pump (rows are divided for evaporator and gas cooler coils), and a four-fan airside evaporator is considered for both hot water heat pumps. For all cases, a design air-side evaporator load (QEv‑design) of 135kW is assumed and the corresponding design fans’ power (QEv fans‑design is expected to be 12kW for the eight-fan evaporator and 6kW for the four-fan evaporators. The fan power for different evaporator source loads (QEv) is calculated using the cube law (Equation 3). The QEv value is obtained from the simulation.

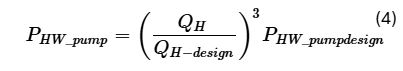

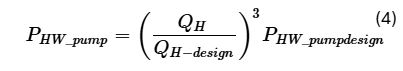

The power required for the hot water pumps is obtained using the cube law, as described in equations (4) and (5).

Where:

Cp_HW is the specific heat capacity of hot water, 4.18kJ/kg K.

ρHW is the density of hot water, assumed to be 1,000kg/m3.

Other parameters are provided in Table 2

Table 2. Assumed parameters for heating performance evaluation.

Cooling performance

Three scenarios are considered for comparing cooling performance:

- R454B air-cooled scroll chiller system: this system is being adopted by major chiller manufactures as a low-GWP alternative to HFC chillers for low and medium air conditioning loads. R454B is an HFO/HFC blend refrigerant with a GWP of 467, which is a close match to R410A-based technology. It is classified as ASHRAE safety class A2L (a slightly flammable refrigerant).

- Chilled water system integrated with transcritical CO2 refrigeration system: some supermarkets have started to integrate the air conditioning load into their main shop floor refrigeration system by allowing a flooded heat exchanger connected to the receiver of the CO2 refrigeration system to produce chilled water.

- Transcritical CO2 heat pump with direct CO2 heating coils into the AHUs and FCUs.

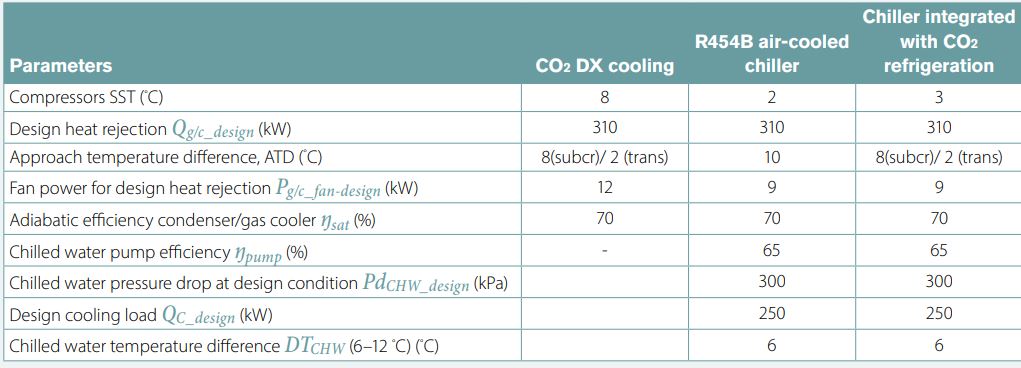

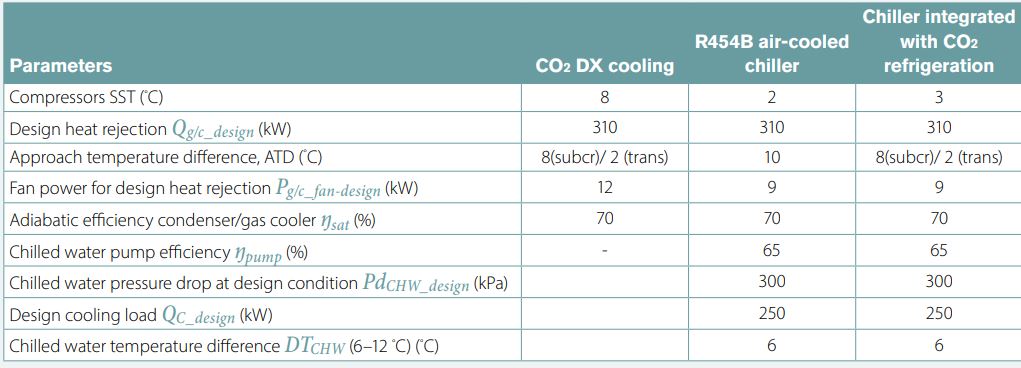

Table 3 provides assumptions used for system performance prediction. Approach temperature difference (ATD) between the outside ambient air and saturated condenser temperature (SCT) of 8oC is used for the CO2 system and an SCT of 10°C is used for the R454B system, which has a significant condensing temperature glide. For the CO2 system, ATD between the outside conditioned air and the gas cooler outlet air temperature is 2oC for transcritical operation.

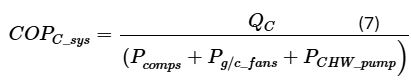

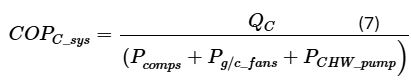

Equation (6) shows the function for compressor cooling COP (

COPC_compsCOPC_comps)

Where QC is the cooling load in kW and Pcomps is the compressors’ power input required in kW. The cooling system COP (COPC_sys ) is defined as the ratio of the cooling load (QC ) and the sum of power inputs to the compressors (Pcomps ), gas cooler/condenser fans (Pg/c_fans) and chilled water pump (PCHW_pump ) if any (see Equation 7).

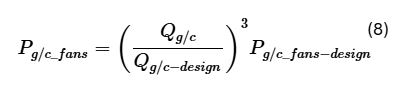

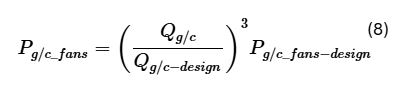

An eight-fan integrated air-side evaporator/gas cooler is assumed for the direct CO2 heat pump, and a six-fan gas cooler/condenser is considered for both chilled water

systems. For all cases, the design gas cooler/condenser heat rejection load (Qg/c‑design ) of 310kW is assumed and the corresponding design fan power (Qg/c_fans‑design ) is

expected to be 12kW for the eight-fan integrated air-side evaporator/gas cooler and 8kW for the six-fan gas cooler/ condenser. The fan power for different heat rejection loads (Qg/c ) is calculated using the cube law Equation 8). The Qg/c value is obtained from the simulation.

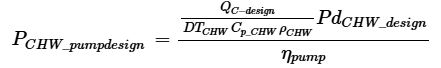

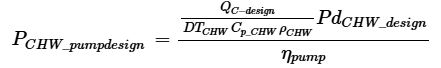

The power required for the chilled water pump is obtained using the cube law as described in equations (9) and (10).

Where:

Where:

Cp_CHW is the specific heat capacity of chilled water, 4.18kJ/kgK. ρCHW is the density of chilled water, assumed to be 1,000kg/m3. Other parameters are provided in Table 3. The adiabatic system is assumed to be activated when the ambient air temperature is 30°C or above. The approach air temperature into the gas cooler (TAir in-g/c) is calculated using Equation 11.

Where ŋsat is adiabatic saturation efficiency, the assumed value is given in Table 3. Tdb is the dry bulb temperature of outside air, in °C. Tdb is the concident wet bulb temperature of outside air, in °C.

Table 3. Assumed parameters for cooling performance evaluation

Results and discussion

Heating performance

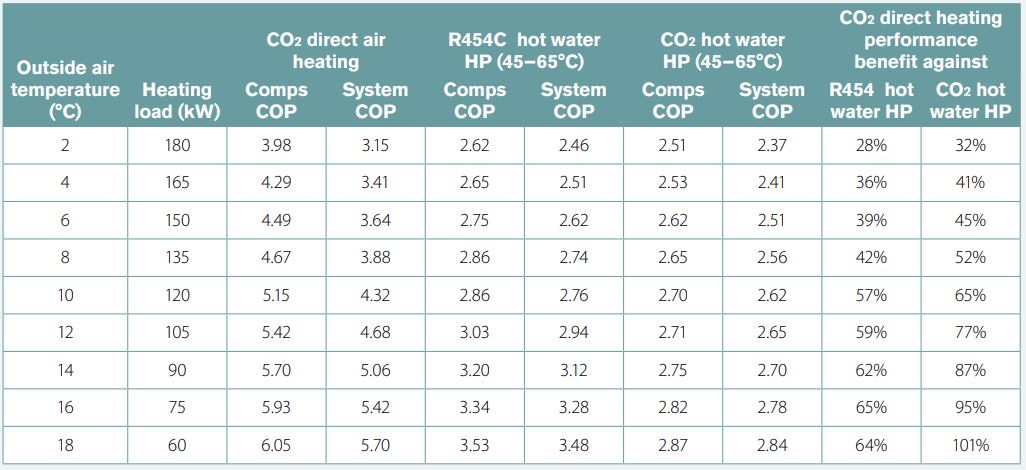

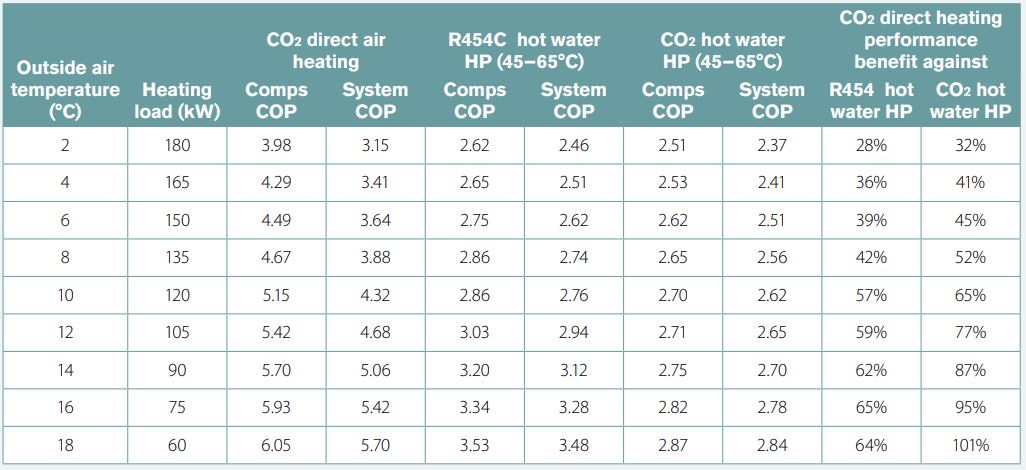

Table 4 presents the heating performance outcomes for the three heating options. As anticipated, the COP of all three heat pump systems decreases as the ambient temperature drops. When comparing the two hot water heat pumps, the R454C heat pump consistently outperforms the CO2 hot water heat pump under all ambient conditions. This performance difference is due to the CO2 hot water heat pump’s COP being highly sensitive to the return water temperature (or generally the sink temperature for any cooling media). A higher return water temperature leads to a lower heating COP.

Using direct supercritical CO2 in the air distribution system helps achieve a low gas cooler outlet temperature from the heating coils, as the coil temperature rarely exceeds 22°C, making a gas cooler outlet temperature of 25°C or lower easily attainable. As shown in Table 4, the direct air heating CO2 heat pump outperforms both hot water heat pumps across the entire range of air temperatures.

The direct air heating CO2 heat pump is between 32–101 per cent more efficient than the hot water CO2 heat pump and between 28–65 per cent more efficient than the R454C heat pump within the considered air temperature range.

Table 4. Performance of CO2 heat pump with direct air heating of the supply air.

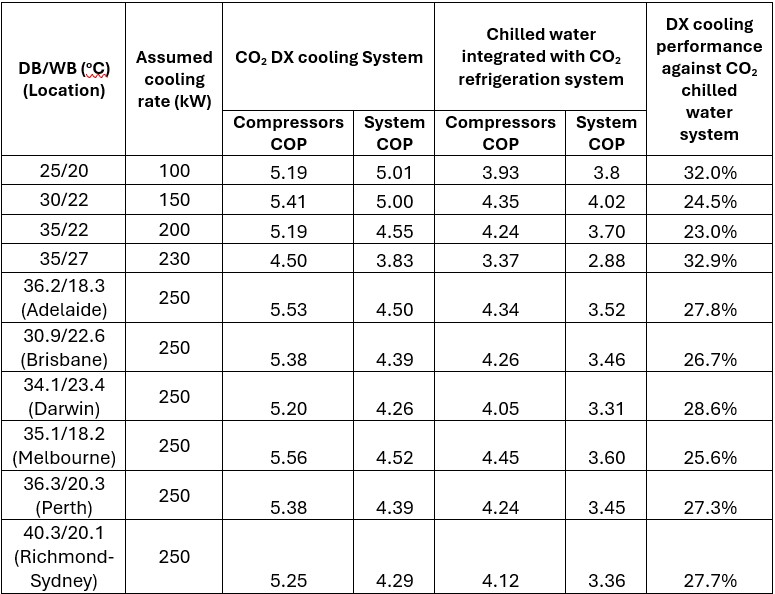

Cooling performance

Performance comparison of CO2 DX air cooling system and R454B air cooled chiller

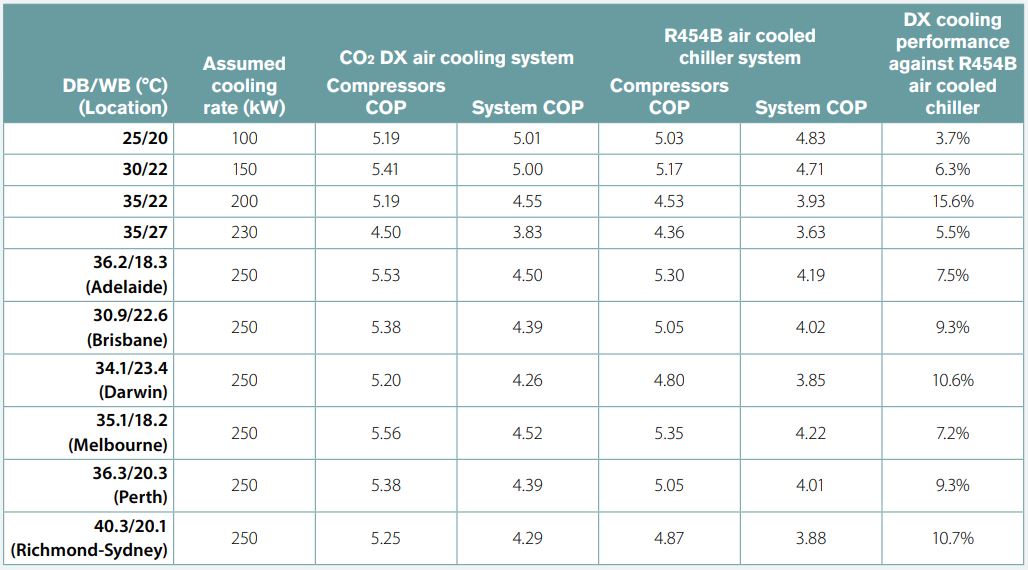

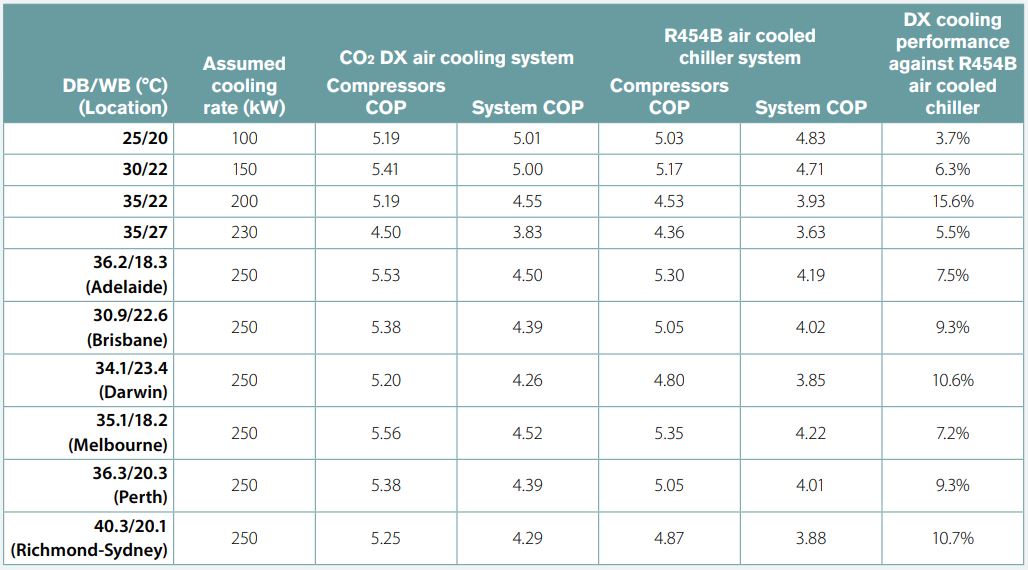

Table 5 presents a performance comparison between the CO2 DX air cooling system and the R454B air-cooled chiller system under various ambient conditions and load scenarios, including the summer design conditions for six major cities in Australia. The CO2 DX cooling system outperforms the R454B chiller for all the ambient temperature ranges considered.

Under the summer design conditions of those six major cities, the CO2 DX air cooling system is consistently more efficient than the R454B chiller, with efficiency improvements ranging from 7.2–10.7 per cent. This performance advantage is particularly important for reducing peak cooling demand, making the CO2 DX system a more reliable choice during periods of high-temperature conditions.

Table 5: Performance comparison of CO2 DX air cooling system and R454B air-cooled chiller

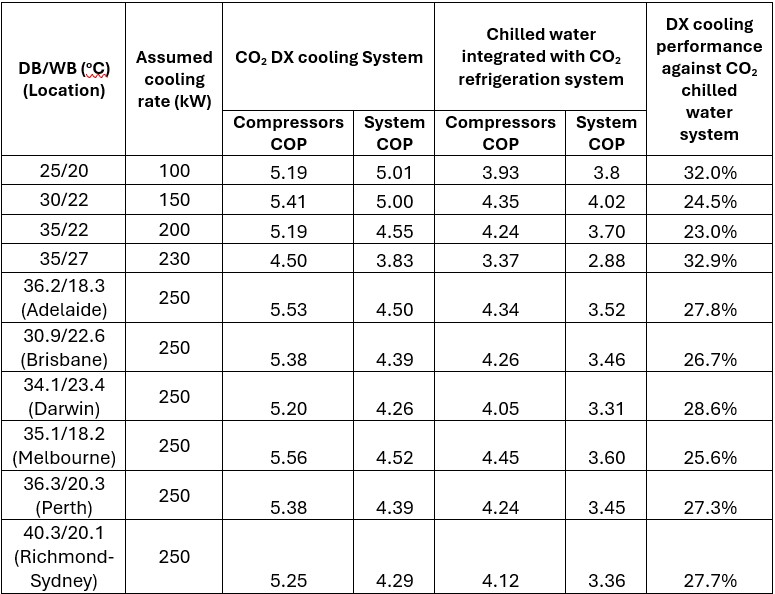

Comparison of CO2 DX cooling system with chilled water system integrated with CO2 refrigeration system

Table 6 provides a performance comparison between the CO2 DX air cooling system and the CO2 refrigeration integrated chilled water system across various ambient conditions and load scenarios, including the summer design conditions for six major cities in Australia.

As expected, the CO2 DX air cooling system consistently outperforms the CO2 refrigeration integrated chilled water system under all considered ambient conditions. This is primarily due to the advantage of operating the CO2 DX system at higher compressor SST.

Under the summer design conditions of the six major cities, the CO2 DX air cooling system demonstrates a significant efficiency advantage over the CO2 chilled water system. Efficiency improvements exceed 25 per cent across all cities, highlighting the CO2 DX air cooling system’s ability to deliver superior performance during peak summer demand.

Table 6: Performance comparison of CO2 DX air cooling system and Chilled water integrated with CO2 refrigeration system

Conclusion

This desktop study demonstrates that CO2 heat pumps with DX cooling coils and CO2 desuperheater heating coils directly into AHUs and FCUs outperform traditional HFO/HFC chilled water and hot water systems for HVAC applications in supermarkets.

CO2 direct air heating heat pumps are 28–65 per cent more efficient than R454C heat pumps for all ambient air temperature ranges for heating.

CO2 DX air cooling systems show a 3.7–15.6 per cent efficiency improvement over R454B air-cooled chillers under the ambient air temperature ranges considered. These cooling performance gains are crucial for reducing energy consumption during peak demand periods in Australia’s varying climates. Additionally, the CO2 DX air cooling system outperforms the CO2 refrigeration integrated chilled water system by over 25 per cent across major Australian cities, providing better cooling efficiency and contributing to operational cost savings, simplified infrastructure, and reduced power demand.

Another advantage of CO2 DX air cooling systems is the substantial reduction in fan power consumption of the air handling units, as they can deliver supply air at lower temperatures (between 9-10°C). Additionally, these systems help improve humidity levels in the occupied space due to the cooler supply air. However, the quantification of these benefits is not provided in this paper.

This study offers valuable insights for supermarkets and other commercial buildings, supporting their transition to more sustainable, energy-efficient HVAC technologies.

References

- Commercial Building Baseline Study 2022, Final Report, viewed on 1/12/2024 https://www.dcceew.gov.au/sites/default/files/documents/commercial-buildings-energy-consumption-baseline-study-2022.pdf , Department of Climate Change, Energy, the Environment and Water (2022)

- Rayne, H.M., Anwar H. K., Isabel, D., Rabi C., Richard G. Derwent,C. A. Taatjes, Andrew J. O., Carl J. P., and Dudley E.S.; Investigation of the Production of Trifluoroacetic Acid from Two Halocarbons, HFC-134a and HFO-1234yf and Its Fates Using a Global Three-Dimensional Chemical Transport Model, ACS Earth Space Chem. 5, 4, 849–857 (2021)

- “Science for Environment Policy”: European Commission DG Environment News Alert Service, edited by the Science Communication Unit, The University of the West of England, Bristol, (2023).

- AS/NZS 5149.1:2016 “Refrigeration systems and heat pumps-Safety and environment requirements, Part 1.”

- Bitzer software “ https://www.bitzer.de/websoftware/”

- AIRAH-AIRAH Technical Handbook-2013, Design Temperature Data, pp.24 (2013)

This article appears in Ecolibrium’s Autumn 2025 edition

View the archive of previous editions

Latest edition

See everything from the latest edition of Ecolibrium, AIRAH’s official journal.