Down to the wire

With a global shortage of copper looming, could aluminium cable be a safe and cost-effective substitute for low voltage underground power supply? Lasath Lecamwasam and Martin Lynch investigate.

The purpose of this article is to discuss the issues involved in shifting from copper to aluminium cables in low voltage underground power supplies to buildings and submains within buildings. The article is broadly split into three sections:

- An explanation of the reasons why this discussion should be had

- An examination of the merits of both copper and aluminium as electricity conductors

- A discussion of the specifications that are important when undertaking a project to install underground aluminium cables.

The context

Several recent studies have concluded that global demand for copper is beginning to outpace its supply. The size of the gap will depend upon the speed with which the renewable energy transition is undertaken, and on the speed at which new copper mines can be developed. If we want to act to achieve net zero emissions by 2050, and the development of new mines continues to proceed at the pace of the past 10 years, then, according to one authoritative study – The Future of Copper by S&P Global – a copper shortfall of at least 3Mt and up to 6Mt per year will persist between 2030 and 2040 and beyond. To put that in perspective, by 2030 about 35Mt in total will be consumed globally, meaning the shortage would be between 10–20% of consumption.

In the light of this looming shortage and the inevitable accompanying price rises for copper, the use of aluminium as a substitute is receiving increasing attention. Using aluminium as a conductor of electricity is by no means a new development; because of its light weight, aluminium has long been used for high voltage overhead transmission lines.

The earliest recorded instance of this was a long-distance transmission line built in southern California in 1899. By the 1950s, aluminium had almost entirely replaced copper in overhead high voltage cables in North America and Europe. Australia followed suit in the 1960s. According to a survey undertaken in 2022, 90% of high voltage overhead cables in Australia are made of aluminium or its alloys. Its use has also spread to medium and low voltage overhead cables, such that two-thirds of Australia’s low voltage overhead cables are also aluminium.

The penetration of aluminium into underground cable networks and inside buildings has been slower. This is in part because aluminium’s weight advantage, which is so important in overhead cables, is not nearly as important underground, and in part because the larger size of the aluminium cable, which doesn’t matter in overhead cables, is a disadvantage underground. However, times are changing. In recent years, the much lower price of aluminium and the looming shortage of copper have provided the motivation to examine whether, and how, aluminium cable can be used more widely underground and as submains cables for distributing power between switchboards inside commercial buildings.

Conductivity comparison

Copper has long been the first choice metal for conducting electricity. This is because it is the best conductor of electricity other than very expensive – and very supply-limited – metals like silver and gold.

The next best conductor is aluminium. While it may be second, it is significantly inferior to copper; for the same size cable – and at the same voltage drop – aluminium is capable of delivering just 62% of the current copper can deliver. To deliver the same voltage and current, an aluminium cable must have 1.6 times the cross-sectional area of a copper cable.

Electrical conductivity is not the only factor when it comes to selecting the material for electrical cable. The cable also needs to resist corrosion, and its connections and terminations to be reliable over many years. Copper outperforms aluminium in both these areas. Let’s take a closer look at how they compare.

Corrosion resistance: There are many types of corrosion, but the main point of difference between copper and aluminium is galvanic corrosion. This is rarely an issue for copper but can potentially cause serious problems with aluminium cable. Galvanic corrosion occurs when two different metals with significantly different standard potentials are brought into contact with each other in the presence of a salt-conducting fluid, such as water.

The reason copper cable rarely creates a galvanic corrosion issue is that the cable is almost always being installed in an environment where every other cable and termination point is also copper, because copper is by far the most common conductor. This means that when aluminium cable is installed, it is usually part of an existing network of copper terminations and cables. In such an environment, there is a high risk of galvanic corrosion because the standard potentials of copper and aluminium differ significantly. Since aluminium is anodic to copper in the electrochemical series, it will be subject to accelerated oxidation.

Terminating and connecting the cable: When it comes to terminating and connecting the cable, copper is superior to aluminium because it has lower thermal expansion and higher creep resistance. These two qualities are not just technical niceties, they may be the most important of all the advantages copper has over aluminium as a conductor.

- Thermal expansion: When a cable conducts electricity, it heats up, and when the electricity is no longer being used, it cools down. This heating and cooling causes the cable and the termination to expand and contract together. If they are made of the same material, they will expand and contract the same amount. However, when they are made of different materials – say, an aluminium cable and a copper terminal – they expand and contract a different amount. In a poorly tightened terminal, the aluminium cable, with its greater extremes of expansion and contraction, can slip out more easily than the copper cable, although in practice this rarely happens.

- Creep resistance: Unfortunately, there’s more to the story. When different metals are subjected to repeated pressures or stresses, some retain their shape while others eventually become permanently deformed. Those that retain their shape are said to be resistant to deformation, or “creep” as it is called. Copper is one such creep-resistant metal. Aluminium, on the other hand, has relatively low creep resistance and so is more susceptible to being permanently deformed. This being the case, after repeated expansions and contractions, aluminium cable is more likely to flatten and slip free of its termination. It is the combination of aluminium’s higher thermal expansion and lower creep resistance that results in the cable slipping free.

When it “slips free” of its termination or connection, the aluminium cable can either partially slip or fully slip. If it fully slips free, then you have a live wire arcing in the switchboard or in the conduit. A partial slip results in a hotspot, which left unattended can also cause a failure or fire. This hotspot occurs because aluminium forms a non-conducting surface oxide layer very rapidly when exposed to air. When the termination of the aluminium cable is first done, this oxide layer is broken when the terminal connection pressure is applied, or when the lug is crimped. If, however, the cable later partially slips free, that section of wire that was conducting electricity oxidises when it comes into contact with air. The result is a smaller section of cable having to do the job of conducting the electricity. This effectively creates a smaller cable, and so the hotspot develops.

Overcoming aluminium’s disadvantages

Both these disadvantages had been well-recognised by the 1950s. Thankfully, there are now reliable remedies for both.

- Thermal expansion and creep resistance – solution 1: This solution lies partly in the development of an aluminium alloy called AA-8030. This was developed in the late 1970s in the wake of a spate of house fires caused by aluminium cables coming loose from their terminations. AA-8030 has creep resistance similar to that of copper, so a cable made from AA-8030 (instead of high purity aluminium) is much less likely to slip free of its termination.

- Thermal expansion and creep resistance – solution 2: In addition to the development of AA-8030, terminals and connections designed specially for aluminium cable have been developed. These will typically have “shark teeth”, which both penetrate the oxide layer (thereby allowing better conduction of electricity across the terminal) and also prevent the cable from slipping free. They may be screw-type hexagonal compression fittings or, for larger cables, crimped lugs.

- Galvanic corrosion: The solution to protect against galvanic corrosion is to prevent any exposed aluminium cable from coming into contact with the air and moisture. This is done in a variety of ways, including using a covering of grease, a coating of chemical spray, a protective plastic sheath, or, for larger cables, a termination point (such as a crimping lug) that fully encloses the cable up to its insulation.

The advantages of aluminium

The main advantage of using aluminium for electrical cable is the price. At the time of writing, the price of aluminium per tonne is US$2,260, while for copper it’s US$10,650, meaning that aluminium costs about 20% of copper per unit weight. For the same current-carrying capacity, one meter of aluminium cable weighs about half of the same length of copper cable. Combining cost per unit weight and weight per unit length, one metre of aluminium cable costs about 10% of the same length of equivalent copper cable.

Of course, the price of the metal is only factor among many.

- Cost of cable insulation: About 25% more insulation is needed per metre for aluminium cable because it has a larger diameter than copper.

- Cost of terminations: The terminations for aluminium cable, being specialised and less commonly used, typically cost more than those for copper cable.

- Cost of installation labour: There may be no difference in labour cost if small diameter cables are being installed. However, with large cables it may be the case that where only two workers are needed for aluminium, there may be five needed for copper. This is because, for the same current-carrying capacity, copper cables weigh twice as much as aluminium. Compounding the problem, the larger copper cables are also much less flexible, meaning more workers are needed to wrestle it into place.

- Cost of cable infrastructure: If aluminium cables are being installed in a new facility, the larger size of the required underground conduit, service ducts or cable trays will increase the cost of the installation. This extra cost is often not large in the context of the price of the cable. However, if the aluminium cables are being installed as replacements for copper cable in an existing facility, and if the underground conduit or even the cable trays have to be expanded, then this will likely become prohibitively expensive and rule out the use of aluminium.

Overall, the cost of purchasing and installing aluminium cable is less, and usually a lot less, than using copper cable. The exception to this is when aluminium cables are being used as replacements for existing copper cables and the existing infrastructure is too small.

The second major advantage of aluminium cable – reliability of supply – is really only relevant in the future if the expected shortage of copper occurs. If this shortage occurs, the price of copper will rise further, and aluminium will have a major advantage over copper due to both its greater reliability of supply and its much lower price.

Installing aluminium underground

From the discussion above, we can see that installing low voltage underground aluminium cables and submains cables within buildings is potentially worthwhile, but only if done properly.

It is important to factor in aluminium’s vulnerabilities when specifying any project. Key elements to consider are:

- Recognising the importance of doing the terminations (lugs) and connections in the right way.

- Selecting the terminations that are suitable for the job. This includes ensuring that the terminations are sealed, or otherwise protected, to prevent moisture ingress, especially in locations that are prone to moisture ingress.

- Designing the installation so as to minimise the number of terminations and, wherever possible, eliminate cable connections entirely by using cables of sufficient length to reach from one termination to the other. Note that aluminium cable is thicker than copper, so a single roll will contain a shorter length than the same size roll of copper cable.

- Using only electricians and other personnel who are trained in the differences between copper and aluminium cables. This involves specifying the training those personnel will need to undertake and potentially being accredited by cable and joint manufacturers.

- Arranging the switchboard so as to allow ready access to the aluminium cable terminations so that condition monitoring, especially thermography, can be done. This includes ensuring that the installation is under design maximum load conditions for at least an hour, so that when thermographic monitoring takes, all HVAC systems are activated in order to put the cables under the correct load. This may be achieved by configuring a “thermography mode” into the BMS.

- Detailing the quality assurance checks to be performed during the installation and commissioning of the new cables. Foremost among these checks is the thermographic testing of the terminations.

Ongoing maintenance

Aluminium cable should have a working life that is similar to that of copper cable. To ensure this, a program of condition monitoring is required for the first 12 months. This involves at least two thermographic tests, the first one to three months post-commissioning and the second at 12 months. Since regular thermographic testing already takes place across many sites, this is not expected to add to the already allocated maintenance expenditure.

Conclusion

With global copper shortages forecast over the next 10 years, we’ll likely need to use aluminium and other substitutes in cases where copper is currently the preferred metal, including underground power distribution networks and submains. This is technically feasible and can be economically advantageous, as long as it’s done correctly.

There are long-standing and proven methods to safeguard against aluminium’s two key vulnerabilities: the increased risk of termination failure and the threat of galvanic corrosion. When specifying project requirements, it is important that these methods are recognised, the correct equipment is selected, and only well-trained personnel are employed to design and carry out the installation. To ensure the soundness of the installation, condition monitoring of the terminations should be done at regular intervals for at least the first 12 months post-commissioning.

About the authors

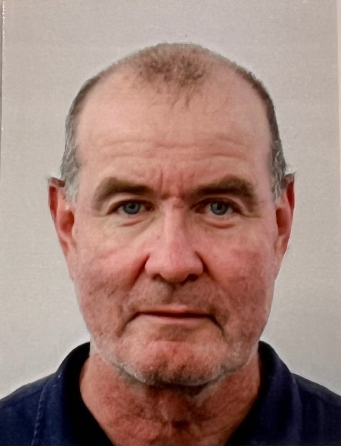

Lasath Lecamwasam, F.AIRAH, CPEng FIEAust, MCIBSE, MASHRAE is the founding director of -Canberra based Engineered Solutions for Building Sustainability (ESBS), which is actively pursuing solutions towards reducing emissions from the built environment.

Martin Lynch, Affil.AIRAH, has, for the past 15 years, owned and managed a renewable energy business, and prior to that worked for 25 years in the mining industry. He is now pursuing a PhD at the University of Queensland, focusing on substitutes for copper.

Lasath and Martin are members of AIRAH’s Electrification Special Technical Group, which actively promotes coordinated and optimised solutions for sustainability.

This article appears in Ecolibrium’s Winter 2025 edition

View the archive of previous editions

Latest edition

See everything from the latest edition of Ecolibrium, AIRAH’s official journal.