Celebrating AS 1668.2, Australia’s misunderstood ventilation hero

Sonia Holzheimer, M.AIRAH, reflects on the good, the bad, and the ugly misunderstood aspects of AS 1668.2.

Next year, AS 1668.2 turns 50. On an aside – so does my husband. And while they’re both a little thicker in the middle these days, only one of them has managed to get less grey over years. Both have endured more than 20 years of me ruminating on their ambiguities, scrutinising their intentions and occasionally negotiating an alternative (where the original request is unworkable), yet they continue to show remarkable signs of resilience.

In an industry where technologies come and go, and temperature setpoints drift, AS 1668.2 has managed to hold its place. Not by reinventing itself every decade, but by quietly doing the job it was designed to do.

That’s part of the problem.

Because when something has been around for a long time, that familiarity can breed contempt, and some may assume it’s outdated or no longer up to the job. We forget the logic behind its design and the context in which it was created, or worse – we expect it to solve problems it was never meant to address.

In the case of AS 1668.2, one of the most consistent examples of this misunderstanding is carbon dioxide (CO₂).

What AS 1668.2 actually does

AS 1668.2 is, and always has been, a design standard for mechanical ventilation – specifically, for setting permissible ventilation rates with consideration for health and ventilation amenity. These include body odour, respired CO₂, and various emissions from people, furnishings, and activities.

It is not a real-time air quality monitor. It is not an infection control framework. And it is not a comfort standard, no matter how much some of us (myself included) wish it were otherwise. I’ve wished my husband could read my mind plenty of times too, but that capability hasn’t evolved in his 50 years either.

The Rolling Stones were right: you can’t always get what you want.

The 1976 “OG” edition introduced a multiple enclosure approach based on a mass-balance view of ventilation, used to derive an optimum outdoor flowrate that delivers at least the minimum required contaminant dilution across all enclosures. It allowed (and still allows) outdoor air reductions where contaminant levels are addressed through filtration or “absorption”. Even then, it acknowledged that a physiological minimum of 2.5L/s/person is sufficient for respiration – a baseline that continues to underpin today’s clauses.

Since then, the standard has modernised its structure, clarified its procedures, expanded its commentary. Importantly, it has been adopted by reference in construction legislation via the NCC. But its underlying logic remains largely unchanged: if contaminants are likely to be present and cannot be exhausted or filtered, we dilute them using outdoor air – preferably in amounts proportional to the number of occupants and the expected emissions in each space.

Because if you try sometimes … you might just get what you need.

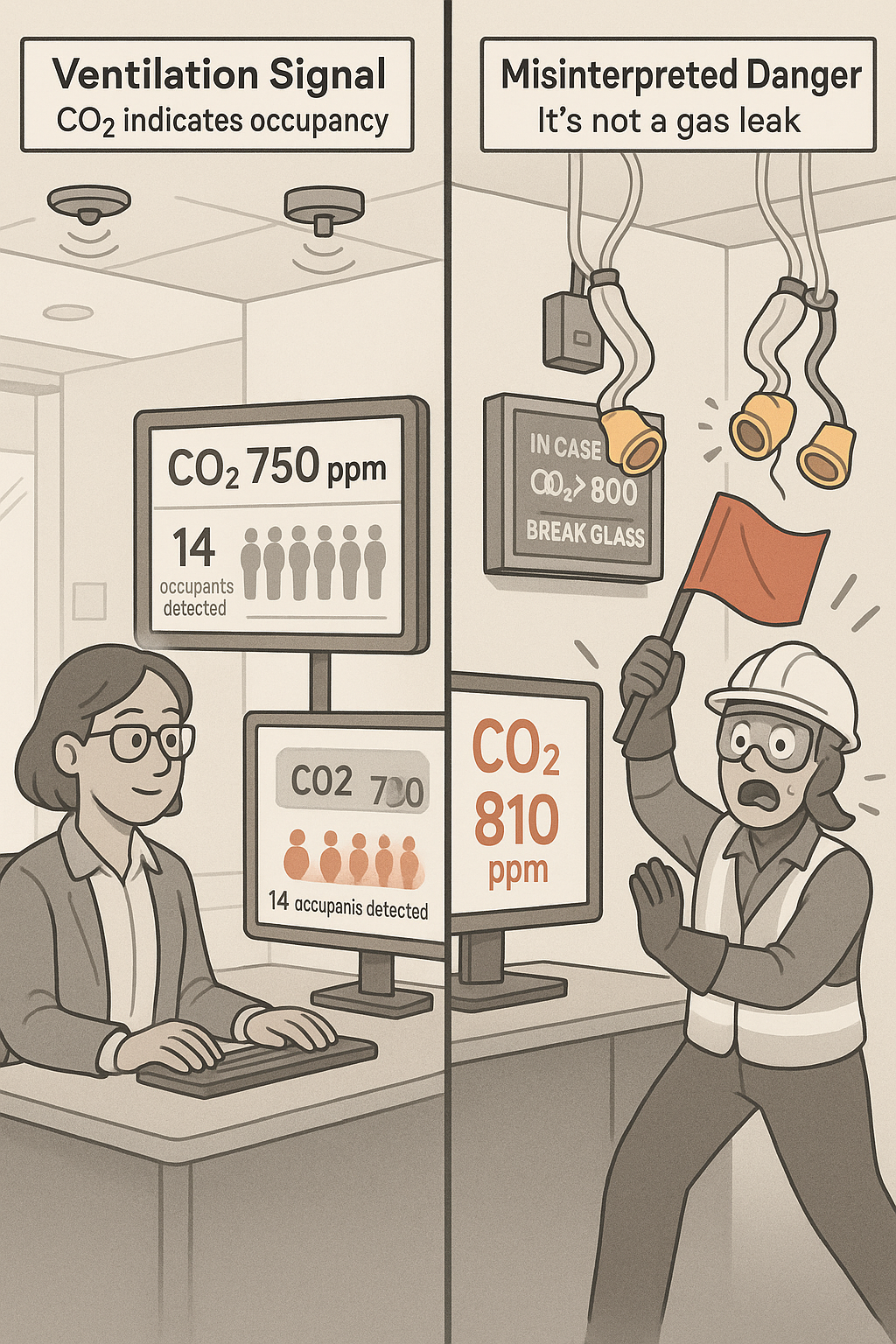

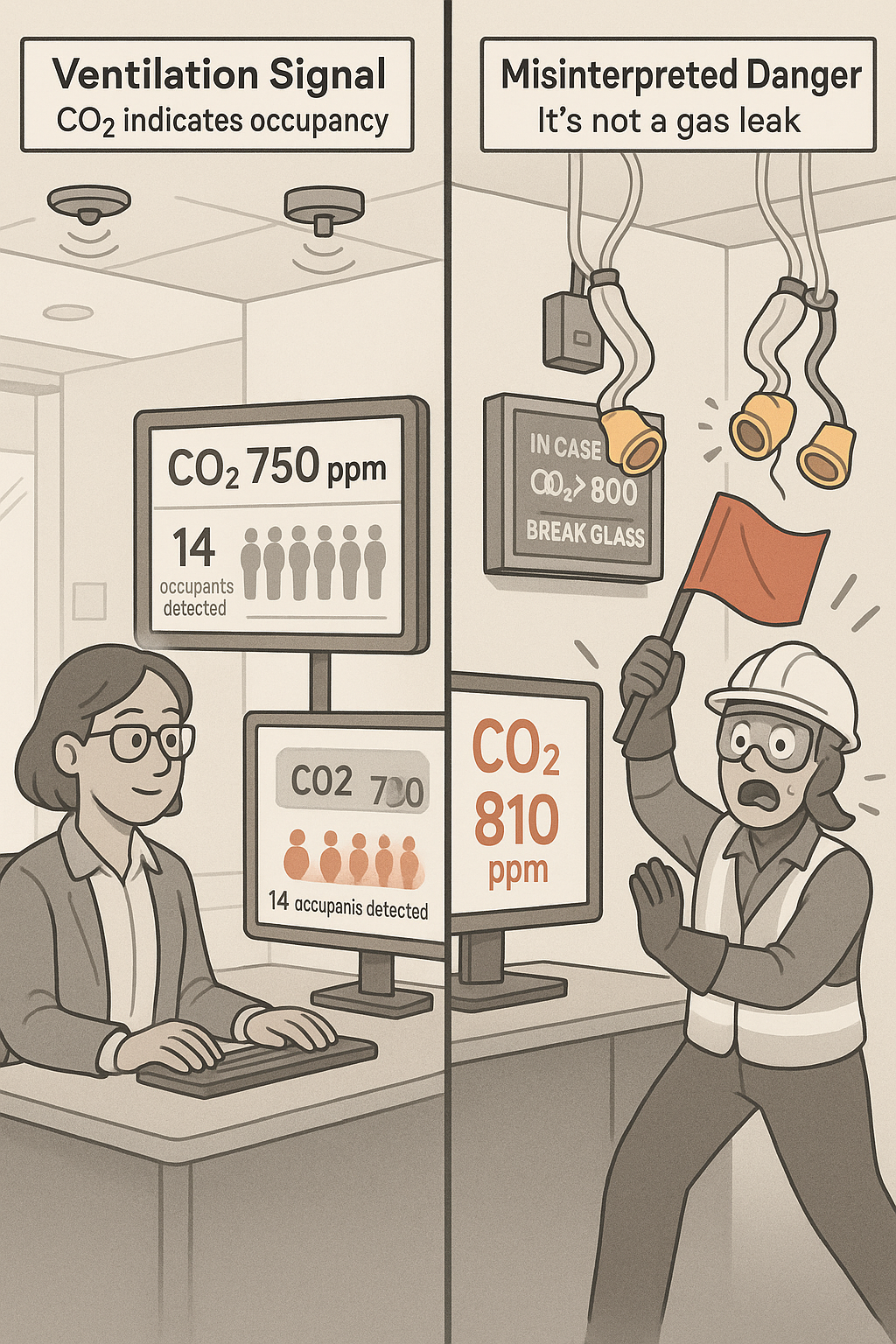

CO₂: The presence of people, not a sign of peril

One of the key misunderstandings in recent years is the assumption that CO₂ thresholds (like 800ppm) represent health-based IAQ limits. In truth, neither AS 1668.2 nor ASHRAE 62.1 make such claims. CO₂ is a control input – a signal that people are present and that the ventilation system may need to increase outdoor air. It can help modulate supply in systems using demand control ventilation (DCV), but it is not itself a compliance metric.

ASHRAE 62.1, through its indoor air quality procedure (IAQP), allows the use of CO₂ in mass-balance models, and includes guidance in its appendices on how to calculate ventilation needs using known indoor and outdoor concentrations. While it does not provide a step-by-step example specifically for CO₂, its mass-balance framework supports this approach, and Appendix N acknowledges that CO₂ can be used as a design contaminant when backed by credible concentration targets. But again, this is a tool, not a health test. CO₂ accumulation is a sign of occupancy and ventilation rate, not necessarily a sign of dangerous air.

AS 1668.2 is even more cautious. It references CO₂ in its commentary and control provisions and offers typical setpoint ranges (sourced from the BCA Vol 1), but it does not mandate any “safe” indoor level. In fact, many misapplications stem from treating informal targets like 800ppm or 1,000ppm and as legislated limits. They’re not.

Making an ass out of you and me

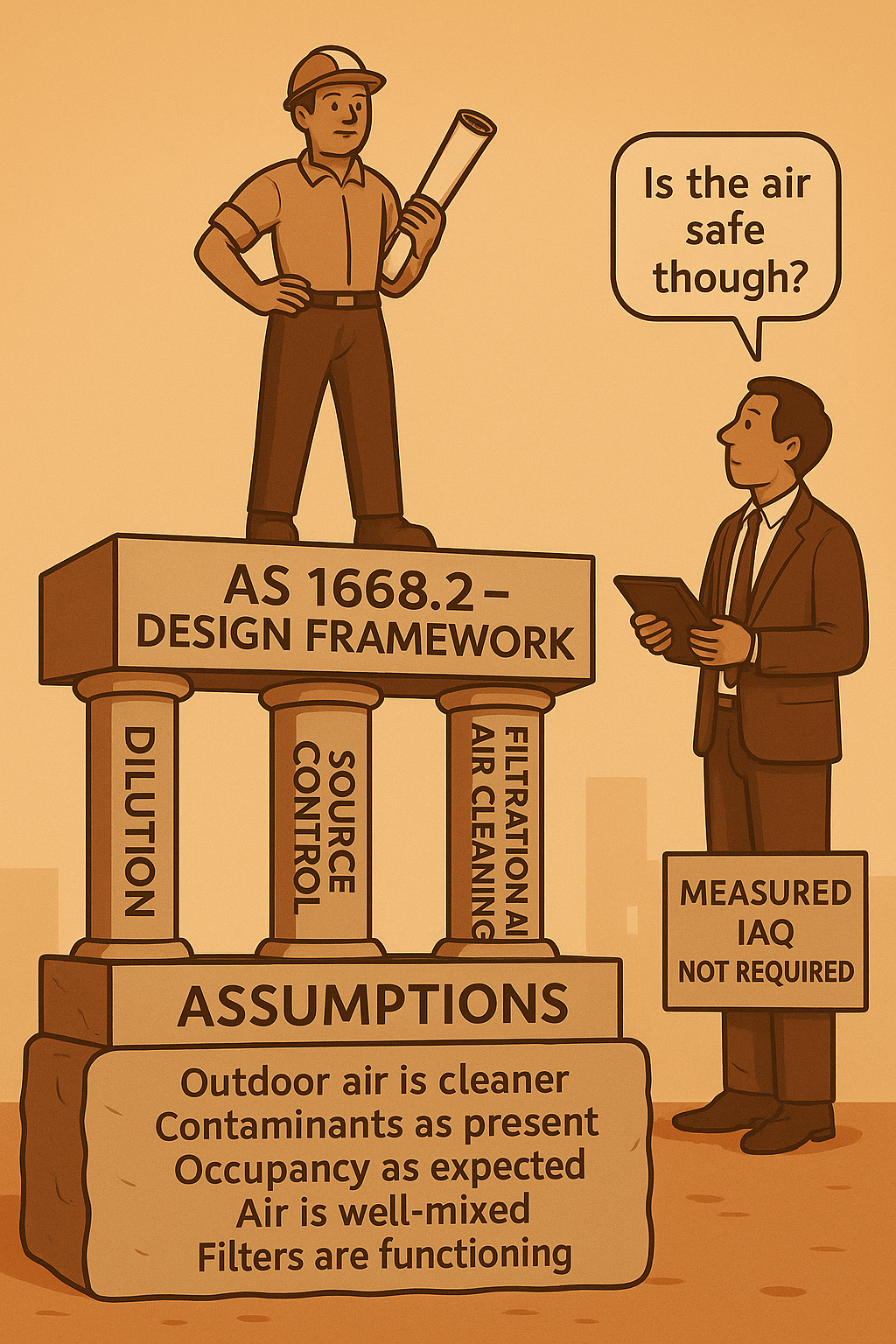

One of the strengths of AS 1668.2 is also one of its limitations: it assumes.

It assumes that contaminants are being generated, that outdoor air is of higher quality than indoor air, and that introducing enough of it – either directly or “effectively” (meaning residual, transferred, treated or filtered) – will maintain contaminant concentrations to acceptable levels. It assumes people will occupy the space as intended, that air is well mixed, and that filtration systems are working. And it assumes that dilution is good enough, because we rarely measure the results.

This is both the brilliance and the vulnerability of the standard. In the absence of measured IAQ performance, it gives us a defensible, engineering-based approach to providing a minimum level of protection. But it doesn’t verify outcomes. It doesn’t tell you if the air is clean – it tells you what to do to probably keep it acceptable.

That distinction becomes even more important as expectations rise. When stakeholders now ask for proof that ventilation reduces infection risk or want real-time dashboards showing that “the air is safe”, it’s not that AS 1668.2 is outdated (although some of the research its assumptions were based on perhaps is) – it’s that we’re asking it to do something it never promised.

So, what’s the problem?

There’s nothing wrong with AS 1668.2 – not if you understand what it is. It’s a design standard, setting out minimum acceptable provisions, not “good practice” or “best practice.” It’s not a maintenance guide, an operational checklist, or an indoor air quality guarantee.

The problem arises when people interpret it as something it isn’t: when CO₂ targets are used as audit checklists, when compliance is reduced to sensor readouts without context, or when outdoor air is pursued on the presumption that more must be better, without consideration for moisture or energy costs.

And sometimes, the problem is that we expect 1668.2 to do all the work. It was never meant to be a complete IAQ solution. It assumes ventilation is the primary tool, but in many modern buildings, the contaminants we worry about won’t be solved by dilution alone. Source control, material choices, filtration strategies, maintenance regimes, and even occupant behaviour all play their part.

What 1668.2 offers is a robust, measurable, and mechanically achievable ventilation rate minimum. And after 50 years, it’s still doing that part of the job quite well.

The forgotten power of Appendix D (and friends)

One of the more underappreciated aspects of AS 1668.2 is that it has never insisted that all outdoor air for ventilation be literally drawn from outside. The 1976 edition introduced the multiple enclosure approach, which acknowledged the contribution of residual outdoor air within recirculated air. The term effective outdoor airflow was formalised in 2012, and includes residual, transferred, treated, or filtered air – all of which can count toward the required ventilation rate.

Appendix D (formerly Appendix G in 1991, and arguably present in spirit as far back as 1976) introduced a concept that should have become mainstream by now: if you remove or reduce contaminants through validated filtration or air-cleaning, you can reduce the amount of outdoor air that must be introduced, because you’re achieving the same dilution effect through other means.

In simple terms: if you clean the recirculated air – air that has already been conditioned and therefore retains its enthalpy – well enough, you can treat it as equivalent to outdoor air for contaminant dilution. However, this equivalence does not extend to oxygen replenishment. That’s why AS 1668.2 still mandates that a minimum of 2.5L/s per person of actual outdoor air must be introduced into each enclosure. This value is not derived from metabolic oxygen demand (which is far lower), but rather represents a minimum requirement to manage the accumulation of respired CO₂ and ensure a baseline level of air freshness and respiration adequacy.

The remainder of the ventilation rate – whether it’s the traditional 10L/s per person or another value based on use type – is primarily aimed at controlling odours and broader IAQ concerns. And if those odours and particulates are effectively addressed by high-efficiency filtration, AS 1668.2 explicitly permits a reduction in required outdoor air under certain conditions.

The catch? This flexibility comes with strings:

- The filtration, cleaning or treatment strategy must be validated and effective

- The contaminants must be known and targetable

- The system must be documented and verified.

In practice, these rarely happen. Why?

Because it’s easier (and lower risk from a certification perspective) to oversize the AHU than it is to design and prove a compliant Appendix D solution. Because certifiers don’t ask. And because – despite its long-standing presence – the filtration and air-cleaning pathway is either forgotten or dismissed as too hard.

That’s a shame, particularly in hot, humid climates where every unnecessary litre of outdoor air carries a moisture penalty. If you could reduce your outdoor air from 10L/s to 5L/s per person through validated odour and particle control, that’s a massive win in terms of dehumidification load.

The standard enables this – and in some cases, actively encourages it – but many in the industry don’t take advantage of it.

Expectation versus reality

AS 1668.2 does more than it gets credit for. But it also doesn’t do everything we sometimes expect of it.

Yes, it allows demand control ventilation using CO₂ – but only as a means of modulating airflow in response to occupancy, not as proof of compliance. This pathway was formally introduced in the 2012 edition, drawing clear inspiration from ASHRAE 62.1, which had supported CO₂-based modulation since the early 2000s. Notably, demand-controlled ventilation is now a requirement under NCC Section J in high-occupancy spaces that exceed certain outdoor airflow threshold rates, where modulation is mandated as part of energy efficiency compliance.

As mentioned above, the standard also allows Appendix D to be used for filtration- and air-cleaning–based concessions to outdoor air requirements. There are both detailed and simplified paths for calculating the required airflow, giving designers flexibility depending on the level of complexity or rigour appropriate to the project.

The 2012 and 2024 editions also include Appendix F – a comprehensive performance-based design pathway that allows engineers to justify alternate ventilation solutions, provided they meet the underlying intent of the standard. This isn’t entirely new; a similar framework was first introduced in the 1991 edition as Appendix G, where proposals could be judged on their merits by a panel of 10 or more assessors. Together, they reflect the standard’s long-standing – but often underutilised – support for engineered alternatives.

So while the standard offers flexibility on paper, its application in practice is at times limited. Some practitioners may default to referencing the outdoor and exhaust airflow rate tables and overlook the more thoughtful, performance-aware opportunities.

That’s fine, until it’s not. Because if your project is in a tropical climate, chasing low-energy, or facing IAQ scrutiny in a post-pandemic world, just ticking the default boxes doesn’t always cut it. That’s when you need to understand the intent of the standard.

And that’s the gap we need to close. Not by rewriting 1668.2, but by better equipping the people who use it.

To be fair, that work is happening and has been for some time. Through AIRAH and dedicated industry educators like the late, great Simon Hill, L.AIRAH, along with many others who’ve helped hundreds of AIRAH members navigate the intent behind the clauses.

But sometimes, we all need a reminder that you don’t know what you don’t know. And in a standard that’s grown more flexible — but also more complex — that humility matters.

The unmentionables

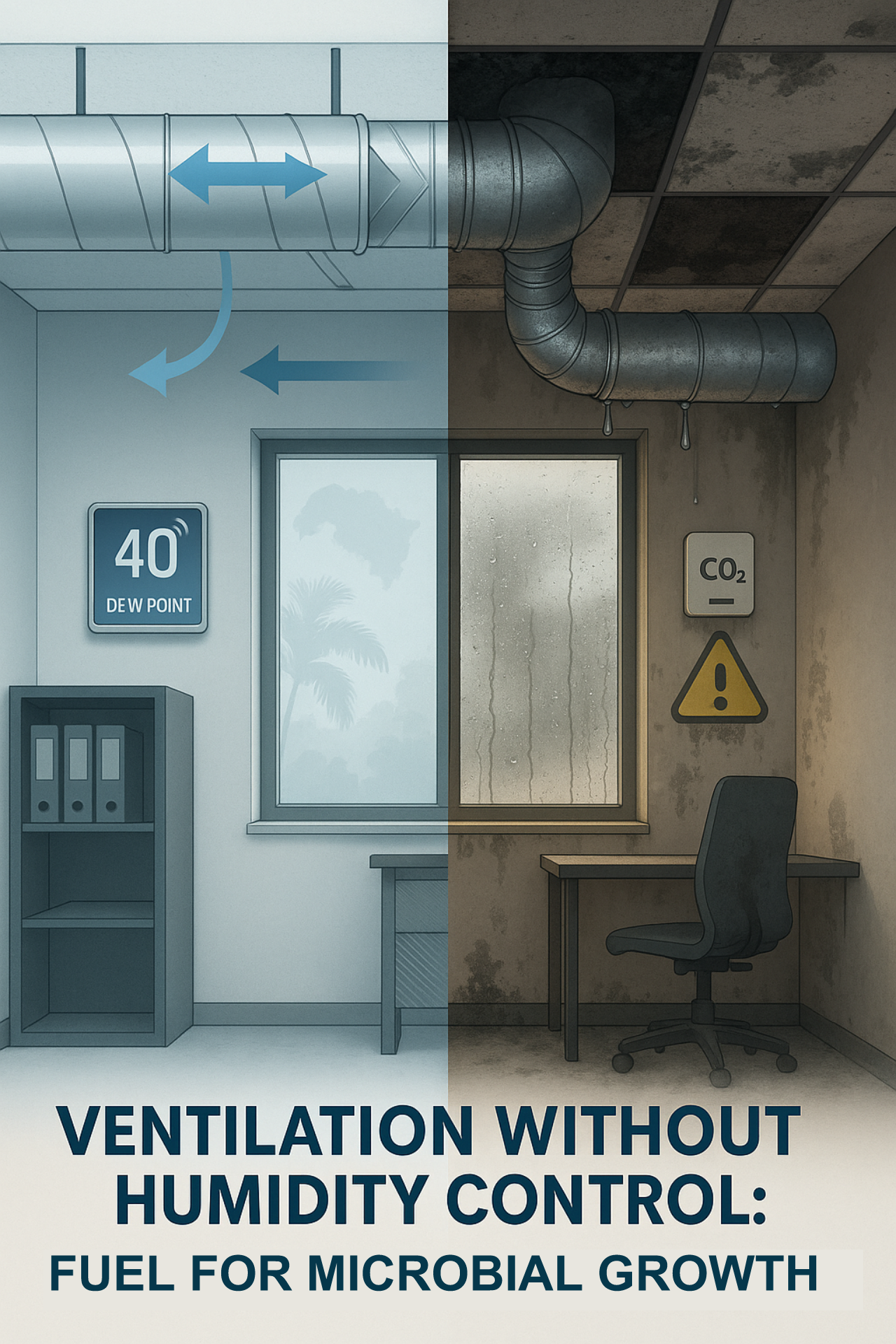

There’s one thing AS 1668.2 almost never talks about. It isn’t airflow. It isn’t CO₂. It’s not contaminants, filters, or energy. It’s water, in the form of vapour: humidity. My nemesis.

For a standard so focused on amenity, AS 1668.2 says almost nothing about humidity control. There are no references to dewpoint limits or latent load management. That’s fine in Melbourne, manageable in Sydney, and occasionally acceptable in Brisbane. But in Darwin, Cairns, Townsville – or any hot-humid zone – ignoring humidity is not a neutral act.

In these climates, outdoor air introduced for ventilation brings with it a serious moisture load. More outdoor air means more latent load, a higher risk of condensation, and a greater likelihood of mould – if systems aren’t designed to manage it. And let’s face it: most systems aren’t. They’re designed for comfort, with temperature as the control point and humidity relegated to an uncontrolled variable – not measured, and therefore not adjustable.

In other words, unless specifically designed for it, humidity control doesn’t exist. The indoor humidity needed to limit the risk of condensation is achievable only under very specific conditions, which, in the tropics, rarely if ever occur.

At least a broken watch is right twice a day.

It’s therefore no surprise that in tropical zones, AS 1668.2 ventilation rates tend to be applied judiciously. Oversupplying outdoor air in pursuit of better IAQ can have severe unintended consequences when the ceiling tiles turn black and the archive room starts smelling like a rainforest.

ASHRAE 62.1 has increasingly accommodated this challenge, offering alternative compliance through the IAQP and credit for validated air cleaning. It also recognises the importance of controlling dewpoint and condensation risk in system and envelope design.

These observations aren’t a criticism of the standard, just a reminder of its scope. AS 1668.2 doesn’t promise to control indoor humidity. It doesn’t assess latent load or specify how to size cooling coils or filter banks. Its focus is ventilation, not moisture control.

The result? Consultants are often left balancing ventilation and contaminant control with dehumidification risks — challenges that fall outside the regulatory framework and are therefore not always supported by project budgets or endorsed by project drivers, to the detriment of the project outcomes.

The grass on the other side

There’s a temptation to think that ASHRAE 62.1 is more advanced than AS 1668.2. And in some ways, that’s true. It has more documentation. It gets updated more often. It offers multiple compliance pathways and allows for performance-based modelling via the IAQP.

But more isn’t always better — sometimes it’s just more.

That “more” is most noticeable in terms of funding and support. ASHRAE has a substantial membership base, dedicated staff, and a commercial publishing model to back its standards development. By contrast, AS 1668.2 is maintained by a volunteer committee under Standards Australia’s detailed update process — which includes a formal proposal, defined scope, committee formation, drafting, public consultation, and consensus — all with limited resourcing and a strong tether to the National Construction Code. That affects not just how often the standard is updated, but also how much change can realistically occur in any given cycle.

🔹 Where ASHRAE 62.1 shines:

- Performance flexibility: The IAQP allows designers to use contaminant modelling to determine ventilation needs and trade off outdoor air for validated filtration or air cleaning.

- Humidity acknowledgement: Later versions include explicit maximum indoor dewpoint limits (e.g. 60% RH max under certain conditions) and recognise the role of latent load.

- Clearer separation of source control, dilution, and filtration: ASHRAE 62.1 treats source control, dilution, and filtration as distinct tools. It prioritises source control where practical, uses prescriptive rates for dilution, and allows filtration to offset outdoor air through the IAQP.

🔹 Where AS 1668.2 holds its own:

- Simplicity and enforceability: The table-based approach, while conservative, is easy to apply and consistent with BCA deemed-to-satisfy pathway.

- Defined minimums: The 2.5L/s/person baseline is based on respiration needs – not odour or comfort — separating health fundamentals from amenity.

- Appendix D flexibility: It permits filtration- and air-cleaning-based concessions – just like IAQP – but does so with less complexity (though arguably too little uptake).

Here’s the thing, though: ASHRAE 62.1 still doesn’t give you a magic CO₂ number.

Like AS 1668.2, it allows CO₂ as a control input – but explicitly rejects using it as a standalone indicator of “acceptable” indoor air quality. Yet across both standards, we still see 800ppm trotted out as if it were a universal truth.

So yes, ASHRAE gives us designers more knobs to turn. But unless those knobs are well-understood and well-applied, they risk adding confusion rather than clarity.

Australia could learn from ASHRAE’s performance-based pathways, particularly as we move toward national IAQ conversations. But we shouldn’t trade away the engineering common sense baked into AS 1668.2 – especially not the parts that have kept it reliable for nearly 50 years.

The good, the bad, and the ugly misunderstood

Just like the song says, I’ll stand by my man — and my standard. I swear AS 1668.2 isn’t ugly, just misunderstood.

The good

- It works

- It doesn’t overclaim

- It integrates effectively with building codes

- It’s designed for Australian practice and (most) local climates

The bad

- Its flexibility often goes unused

- It doesn’t account for humidity

- Its appendices are often ignored

The misunderstood

- Lower CO₂ levels ≠ safe air

- Comfort ≠ IAQ

- Regulators want simplicity, but these issues are complex

People expect AS 1668.2 to be everything, but it just isn’t.

Final thoughts

AS 1668.2 isn’t perfect.

It’s consistent. Practical. Utilitarian. Understated.

It’s the 1976 Holden Kingswood of standards – more capable than a Gemini, but certainly no Statesman.

It won’t deliver “safe” air in every situation, but it gives you a baseline of the requirements for mechanical ventilation, setting the minimum standard we’re legally required to provide. When used as intended, it’s still one of the most useful standards in our field.

As it turns 50 next year (and my husband politely reminds me that he’s not the only one showing signs of wear), I think we need to stop asking 1668.2 to be something it’s not. It doesn’t need to be more; it’s already enough. Its scope just needs to be understood.

Instead of asking AS1668.2 to solve all our problems, maybe it’s time we planned for something new.

About the author

Sonia Holzheimer, M.AIRAH, is a Cairns-based mechanical engineer with more than 20 years of experience in HVAC&R and building services. She is the co-founder of SEQUAL Consulting Group and the chair of the Women of AIRAH Special Technical Group.

References

- Standards Australia. (2024). AS 1668.2:2024 – The use of ventilation and airconditioning in buildings – Mechanical ventilation in buildings. Standards Australia.

- Standards Australia. (2012). AS 1668.2:2012 – The use of ventilation and airconditioning in buildings – Mechanical ventilation in buildings. Standards Australia.

- Standards Australia. (2002). AS 1668.2:2002 – The use of ventilation and airconditioning in buildings – Part 2: Mechanical ventilation in buildings. Standards Australia.

- Standards Australia. (1991). AS 1668.2:1991 – The use of mechanical ventilation and airconditioning in buildings – Mechanical ventilation for acceptable indoor air quality. Standards Australia.

- Standards Association of Australia. (1981). AS 1668.2–1981 – The use of mechanical ventilation and air-conditioning in buildings. Standards Association of Australia.

- Standards Association of Australia. (1976). AS 1668.2–1976 – The use of mechanical ventilation and air-conditioning in buildings. Standards Association of Australia.

- ASHRAE. (2022). ANSI/ASHRAE Standard 62.1-2022 – Ventilation for Acceptable Indoor Air Quality. American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- ASHRAE. (2007). ANSI/ASHRAE Standard 62.1-2007 – Ventilation for Acceptable Indoor Air Quality. American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- Australian Building Codes Board (ABCB). (2022). Indoor Air Quality Handbook. Canberra: ABCB.

- Kowalczewski, J.J. (1973). Quality of Air in Air-Conditioning. Australian Refrigeration, Air Conditioning and Heating, February 1973, pp. 14–17.

- AIRAH. (n.d.). Application Manual DA26 – Indoor Air Quality. Australian Institute of Refrigeration, Air Conditioning and Heating.

- Sherman, M.H., & Logue, J.M. (2010). Why We Ventilate. Lawrence Berkeley National Laboratory. Retrieved from https://escholarship.org/uc/item/9bw5z34b

- Persily, A.K. (2000). CO₂ as an Indoor Air Quality Metric: Is it Appropriate? Indoor Air, 10(4), 343–346.

This article appears in Ecolibrium’s Spring 2025 edition

View the archive of previous editions

Latest edition

See everything from the latest edition of Ecolibrium, AIRAH’s official journal.