Could H2O be the go?

Dave Peall, M.AIRAH, discusses his work on the “radical” idea of using water as a direct expansion refrigerant.

Once upon a time, in a land far, far away from my Rockhampton apprenticeship, I was enjoying one of my career diversions as chief engineer of the Cambridge Holiday Inn. Based more on idle curiosity than a career-defining ambition, I boarded an evening train to London. My destination? The Institute of Refrigeration.

That night’s lecture raised a fascinating question: Could water be used as a direct expansion refrigerant (DX) in a vapour compression system?

The lecturer concluded that water was cheap and readily available, but its benefits as a refrigerant were outweighed by practical limitations; conventional machinery and ancillary components could not easily be adapted for use with water. At the time, the HVAC&R industry was besotted with the new R134a gas, which wasn’t inordinately expensive and didn’t require reskilling by refrigeration technicians. From the presenter’s point of view, water wasn’t really a viable option.

One brave soul asked whether it would be possible to air condition a house using water as a DX refrigerant, as opposed to the status quo approach of using wall-mounted splits or evaporative coolers. I remember the presenter peering over his glasses at the inquisitor before delivering his pessimistic conclusion: it was technically possible, but one would need a compressor the size of the house to handle the volume of suction vapour.

While I was fascinated by this discussion, its true relevance only dawned on me decades later.

Direct expansion refrigeration: the theory

Before picking apart that lecturer’s conclusions, let’s take a look at some of the relevant principles of refrigeration.

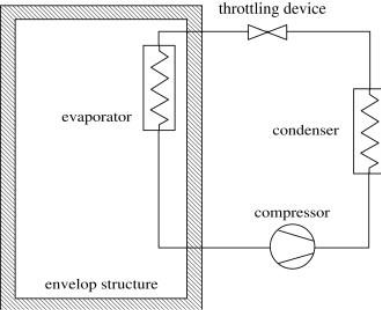

Lowering the temperature of a substance – whether it be fish or a computer chip – involves removing and transferring heat. Modern refrigeration and air conditioning is based on theorising and experimentation going back centuries. As can be seen in Figure 1, a compressor is the mechanical heart of a vapour compression system, with in-line piping connecting to two heat exchangers.

Fig 1

Starting at the top, a throttling device controls liquid refrigerant flow to the evaporator, where it boils by absorbing heat from its surroundings. The heated, low-pressure vapour is drawn back to the compressor, where it is transformed according to Charles’s Law and Boyle’s Law.

As the gas is compacted to a higher pressure – and a correspondingly higher temperature – it flows into the appropriately named condenser. Heat that was removed in the evaporator is rejected to air flowing over the condenser, thereby converting the gas to a high-pressure liquid.

Based on cooling requirements, liquid refrigerant is supplied to the evaporator by the throttling device. The refrigerant is then back where it started in the hamster wheel cycle. In a properly designed and manufactured system, this process can continue ad infinitum, as long as the compressor keeps pumping and the gas doesn’t escape.

Apart from substituting two pumps with a compressor, the technical requirements of a vapour compression system haven’t really changed since Jacob Perkins patented his invention in 1834.

With this in mind, I’m currently undertaking a Master of Philosophy [Mechanical Engineering] at the University of Wollongong, having worked for five decades as a refrigeration technician. I aim to disrupt conventional thinking and redesign <30kWr (kilowatt of refrigeration) domestic and light commercial air conditioning and water heating using H2O as a DX refrigerant. My goal is to use this technology to reduce operational costs and minimise environmental impact.

H2O’s properties as a refrigerant

Now let’s look at why water is worth considering as a DX refrigerant and the challenges we’d need to overcome to make this possible.

Upsides

Water has plenty going for it as a refrigerant. Here are some of the positives:

Refrigerating power: Water is one of nature’s most powerful refrigerants and has been used in this role for thousands of years, so much so that it even has an ASHRAE-designated identification number: R718. Thanks to its high latent heat of evaporation of 2,501kJ/kg at 0°C, water in DX mode has a staggeringly effective propensity to absorb heat. The comparative phase change latent heat of evaporation of HFO-1234yf is a mere, but industry-accepted capability of 164kJ/kg at 0°C.

Safe to handle: Water is intrinsically safe, non-toxic, non-flammable and non-explosive. Unlike all chemical refrigerants and other naturals – including CO2 and ammonia – water is inestimably unlikely to cause oxygen depletion and suffocation when accidentally released into an occupied space.

Eco-friendly: H2O is 99.9% environmentally friendly as it has negligible ozone depletion potential (ODP) and zero global warming potential (GWP). It is readily available and cheap, even in if required in a distilled or demineralised form.

Adaptable: Water can be adapted for low temperature use by adding glycol or graphene. In a pinch – such as in remote areas – hand cleaning gel or methylated spirits could work.

Low-pressure operation: Water safely operates at pressures far lower than those encountered with all other commonly used refrigerants. H2O heat exchangers would be considerably smaller and could conceivably include injection moulded polymers, which have greater conductivity than stainless steel.

Downsides

If you ponder the psychrometric characteristics of water being married to traditional vapour compression mechanics, it seems foolhardy to combine the two and expect water to behave in a similar fashion to other commonly used refrigerants. Here are some reasons why:

Vacuum requirement: Water’s psychometric chart tells us that the evaporator must operate at a vacuum, which presents challenges – after all, nature always strives to occupy negative spaces. This traditionally leads to the ingress of air, which quickly becomes a non-condensable, non-desirable intruder.

Heat capacity: The sensible heat capacity of water vapour is very low; this requires large volume flows, which then demand relatively high compression ratios so the vapour can condense back into a liquid. Compared with classical refrigerants like R134a or R290, water requires approximately 200 times the volume flow, and about double the compression ratio for similar applications.

Insulation problems: Traditional sealed or semi-sealed compressors have exposed, single-insulated electric motor windings. Water can cause this insulation to decompose, leading to catastrophic burnout.

Oil and water: Rotating compressors rely on oil to lubricate moving parts. Unfortunately, water does not mix well with oil. These issues could be circumvented by using magnetic bearing oil-free compressors, which can operate in excess of 50,000rpm, but are currently only offered for use in systems over 50kWr capacity. An open-drive compressor could be used if the oil–water mix lubrication issue were resolved.

H2O as a secondary refrigerant

While H2O hasn’t yet been successfully used as a DX refrigerant for the reasons discussed above, it has a surprisingly long history as a secondary refrigerant.

After developing the first unitary air conditioner in 1902, Willis Carrier progressed to build central plant systems using centrifugal compressors to reduce humidity in textile mills and printing presses. The concept was adopted for multi-storey buildings. Direct expansion and supply of refrigerant to each floor was common practice, but at some stage, water was introduced as a cheaper option as a secondary refrigerant.

Water is still commonly used as a secondary refrigerant in large commercial projects. However, it is gradually being overtaken by VRV/VRF systems circulating large amounts of synthetic refrigerant, including the “mildly flammable” R32.

Using hydrocarbons or ammonia in confined or occupied spaces comes with flammability and toxicity risks. However, these could be mitigated through the use of H2O in secondary or DX refrigerant roles.

Resistance to change

In 1834, Oliver Evans colluded with Jacob Perkins to build an experimental volatile-liquid, closed-circuit vapour compression system. In 1851, Australian refrigeration pioneer James Harrison built the first commercially viable ice-making machine using similar principles.

Nearly two centuries later, the same vapour compression technology is still being used in 80% of global refrigeration and air conditioning. Over half a century of involvement, I have seen that the HVAC&R industry is slow to break away from traditional practices. Indeed, at a conference earlier this year, I saw a company “introduce” a process that was first patented in 1906.

Research shows us that radical, out-of-the-box thinking is a pre-requisite when considering water for use in a vapour compression system.

With the environmental impact of refrigerants in the spotlight like never before, I’d argue that now is the time for such thinking.

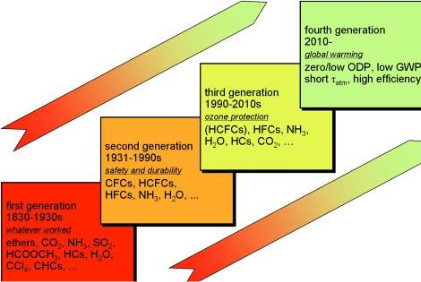

The four generations of refrigerants

In 2008, James Calm segmented refrigerant development into four distinct phases.

- First generation refrigerants (1830–1930) encompassed almost anything that worked, including ether, sulfur dioxide, methyl chloride, ammonia, hydrocarbons and carbon dioxide. Safety concerns raised after explosions involving methyl chloride and hydrocarbons inspired Midgley, Henne and McNary to synthesise the first chlorofluorocarbon (CFC) refrigerant in a GM Research laboratory in 1929.

- Second generation refrigerants (1931–1990) included CFCs, HCFCs, NH3 and CO2. Synthetics became the OEM gases of choice, and sales were accelerated by equipment servicing leakage rates up to 80% – a million tons of freon 12 were allegedly manufactured annually. Freon 11, 12, 22 and 502 lost their stranglehold in the mid-‘80s, when a hole in the ozone layer was discovered, after the industry had dismissed scientific predictions in the mid-‘70s that CFCs would enter the stratosphere where solar radiation would cause the release of highly destructive chlorine atoms.

- Third generation HFC refrigerants (1990-2010) were heralded as being less environmentally damaging, until it was discovered they have significant GWP. Many countries have committed to phasing down these refrigerants, or eliminating them entirely, with the move ushering in a necessary revival of natural refrigerants.

Fourth generation refrigerants (2010–) include natural options such as hydrocarbons, ammonia and CO2. I would argue that water should also be part of this list. Hydrofluoroolefin (HFO) refrigerants – which have universal acceptance by the automotive industry as the only safe replacement for R134a, and are also used in some stationary applications – are also considered fourth generation refrigerants. HFOs have been engineered to fall below designated GWP limits. Unfortunately, they love to bond with atmospheric moisture. With some HFOs being designated as “forever chemicals”, their increasing detection in vegetation, ground, sea water and wildlife is causing justifiable international concern.

Applications of H2O as a DX refrigerant

Safety issues posed by unintended release of hydrocarbons and ammonia into occupied or confined space can be negated by using water as a DX refrigerant. The potential uses for refrigerant being factory sealed in an externally located casing are almost limitless.

The goal of my university research project is to design and build a heat pump, heat recovery energy hub primarily for use in the <30kWr domestic and light commercial market.

Stackable outdoor units will be designed to use renewable energy and a hybrid hydrocarbon refrigerant. System efficiency will be improved by substantially increasing refrigerant-to-heat exchanger surface contact. Water will be used as a direct expansion rather than a secondary refrigerant using a single compressor cascade configuration. The system will significantly reduce the demands of energy-hungry electric resistance heaters and air conditioning compressors, thereby freeing storage batteries at night to feed power back to the grid.

Much of the theoretical work is done – now I have to concentrate on building and testing a working prototype. To do this, I need to safely collaborate with industry experts who have global manufacturing and distribution capability. There are significant technical hurdles, but perhaps the biggest challenge is bringing about change in what can be a conservative industry. My quest to expand on Jacob Perkins’s dream might be reminiscent of Don Quixote’s, but it’s one I think is worth embarking on.

Conclusion

If we accept the historical premise that a leak-free HVAC&R vapour compression system will ever exist, then chemical refrigerant release will always pose a threat to life, land, water or atmosphere. In my mind, the only sustainable option is to change to natural refrigerants – hydrocarbons, ammonia, carbon dioxide and water – as quickly as possible.

About the author

After more than half a century as a fridgie, Dave Peall, M.AIRAH, is undertaking a Master of Philosophy (Mechanical Engineering) degree at UoW, concentrating on improving air conditioning efficiency and sustainability by using water as a direct expansion refrigerant.

This article appears in Ecolibrium’s Spring 2025 edition

View the archive of previous editions

Latest edition

See everything from the latest edition of Ecolibrium, AIRAH’s official journal.