District heating and cooling could offer an important pathway to decarbonisation – and one of the biggest barriers to its uptake might simply be our mindset, writes Mark Vender.

We think nothing of paying for electricity that is generated elsewhere and then delivered via the grid to our home or office. We routinely use other shared services such as internet, water and sewage, all of which rely on a larger infrastructure. When it comes to heat and coolth, however, we cling to the notion that these must be generated onsite, by privately owned equipment.

Perhaps there is a better way.

District heating and cooling (DHC) uses local energy networks to provide heating and cooling to buildings in a district. They do this by supplying hot water or steam for heating systems, and chilled water for air conditioning.

The district may comprise a small group of buildings on a university campus. Or it could be much larger, as in Denmark, where about two‑thirds of residential dwellings are connected to district heating.

SHINING A LIGHT ON DHC

A recent event in Melbourne organised by energy company Engie and the Asia Pacific Urban Energy Association (APUEA) explored DHC and the opportunities it presents.

APUEA executive director Peter Lundberg believes that DHC has a major role to play in decarbonising the built environment.

“DHC may result in up to 50 per cent reduction in energy consumption, 50 per cent reduction in CO2 emissions and refrigerant fluid leaks,” he says.

“It may combine various end‑users of different activities – office, residences, shopping centres, supermarkets, universities – in one system. This diversity reduces the peak heating and cooling demand, as not all buildings have their peak at the same time, and results in smaller plant. It is possible to reduce the installed capacity by up to 30 per cent.”

Thermal storage systems can play a complementary role. Lundberg says that these can further reduce the peak mechanical capacity of DHC systems, and can help increase the use of renewable energy by storing chilled water produced with intermittent renewable electricity.

Other benefits of centralised systems include lower operation and maintenance costs, more space in individual buildings, and reduction of urban heat island effects. They can facilitate multiple production plants. And they can use sources of “free cooling” including, rivers, lakes, geothermal, and also waste energy where available.

PICK YOUR DISTRICT

Presenters at the Melbourne DHC event explained that DHC is best suited to developments with a mix of usage types or with constant heating and cooling demands.

“This is where the systems have greater benefits and relatively quick paybacks,” says Muhammad Ali, M.AIRAH, technical director DHC at Engie Net Zero Energy Solutions.

“Heating and cooling load density (kWth/km²) also plays an important role in the feasibility of DHC systems. You can find district heating and cooling plants in universities, airports, hospitals, CBD, and transit‑oriented development (TOD) areas, industrial zones, municipalities and cities.”

In Australia, DHC has been successfully implemented in some universities – including Monash in Victoria and the University of Queensland – but has struggled to gain traction in other settings. Ali agrees there are challenges for wider uptake.

“DHC technology is more than 100 years old and it has proven itself as technically and commercially viable,” he says. “Yet its penetration in different market and regions has met different challenges.

“Factors that decide the success of a district heating and cooling system include load density, ramp‑up (periodic addition of new end‑users), initial cost of piping network, permits and licences, and interfaces with building systems.”

Ali also notes that there is a cultural barrier to overcome in some places.

“In some geographies, there is not a great penetration of DHC because it is still considered a foreign idea and its benefits are not properly realised,” he says. “With the recent net zero ambitions, DHC is being realised as a potential solution to decarbonise heating and cooling networks, and is being considered an important lever in the journey to reach net zero.

“This will surely increase the penetration of technology in new geographies. After all, DHC systems can be seen as a utility similar to electricity, water, and sewage, as they provide many benefits to our cities and communities.”

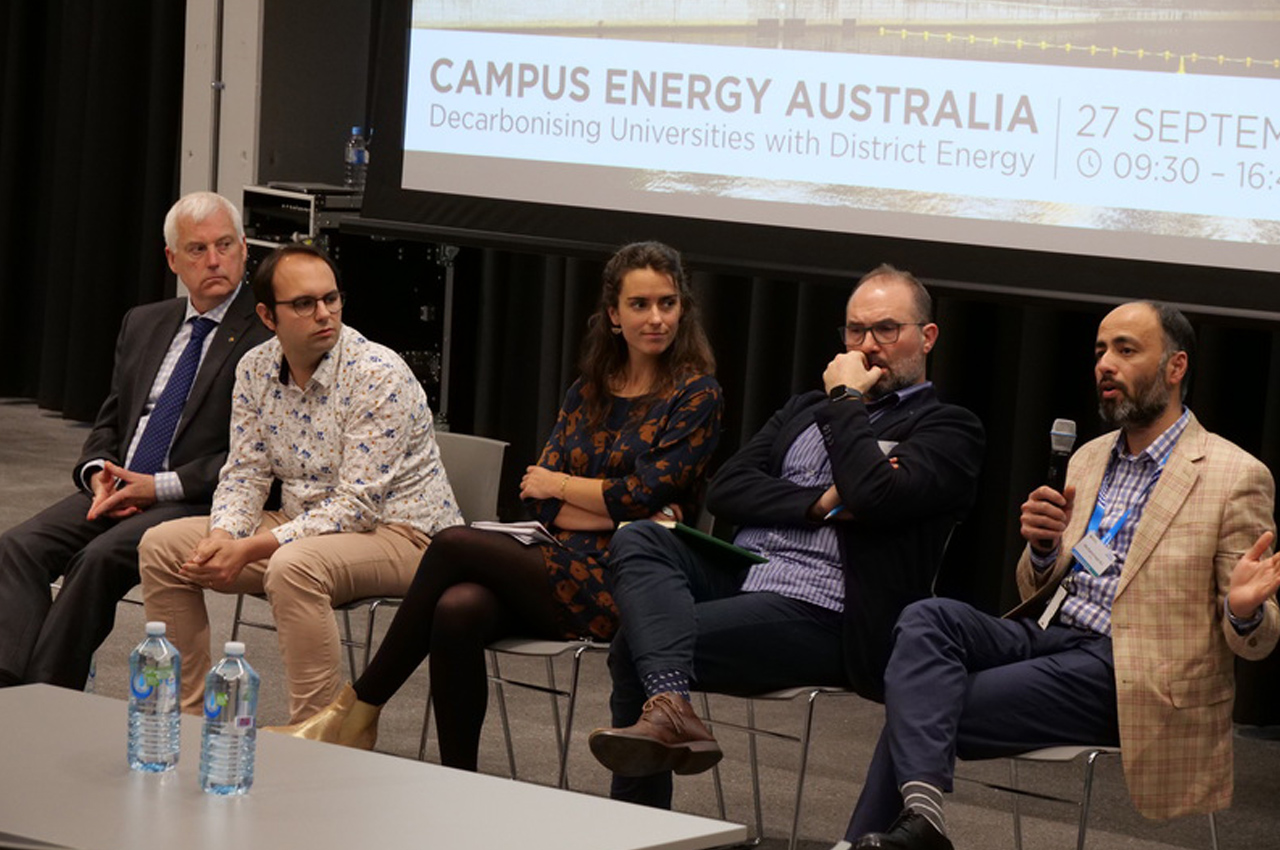

A panel session from the Campus Energy Australia event in Melbourne featuring (from right) Muhammad Ali; Melbourne Energy Institute energy systems program leader Pierluigi Mancarella; ClimateWorks Centre cities system lead Margot Delafoulhouze; Engie impact decarbonisation lead Niels Leemput; and AIRAH chief executive Tony Gleeson, M.AIRAH.

LOCAL EXPERIENCE

One of the attendees at the Melbourne district energy event was Michael Snow, associate director, carbon neutral and university infrastructure at RMIT University, and a proponent of DHC technology.

Snow cut his teeth in the energy industry in cogeneration, during its heyday in Australia. Although the systems were effective at providing electricity and hot‑water, a lot of heat was wasted. Frustrated by this, Snow and his colleagues looked to the European district systems for ideas.

They noted some big differences between Europe and Australia. Whereas our focus was on electricity loads, in Europe they focused more on heat loads.

“They view energy fundamentally differently,” says Snow. “We look at a cooling tower as something you need for a chiller. They look at a cooling tower, aghast, as to why would you waste that energy?”

Some of this can be traced right back to the oil crisis of the 1970s.

“Energy has been historically very cheap in Australia, and we weren’t affected by the oil price shocks to the degree they were” says Snow. “We had some lines at the petrol station; they had fundamental crises with their energy system. So they rethought things.”

DHC DOWN UNDER

Despite the differences, some larger projects did reach various states of completion in Australia.

In the early 2010s in Melbourne, a $290m project initiative sought to revitalise central Dandenong with a seven‑hectare mixed‑use development boasting strong sustainability credentials. Key to this was the Dandenong Precinct Energy Project (PEP) – a distributed energy cogeneration plant that provided an effective way for businesses in central Dandenong to access lower carbon electricity and thermal heating and cooling.

Unfortunately, technical and commercial challenges meant the project goals were not achieved. While connection to the network was strongly encouraged during the development‑approval process, it could not be mandated. This led to a situation where developers refused to connect unless energy could be provided at significantly lower prices, which wasn’t possible due to the relatively low energy density of the load on the network during early stages of the precinct’s build‑out.

In Sydney, the Decentralised Energy Master Plan Trigeneration 2010–2030 sought to connect 65 per cent of all commercial floor space, 50 of all retail floor space, and 30 per cent of all residential floor space within the City of Sydney to low‑carbon electricity and zero carbon heating and cooling.

But the project never came to fruition. One issue was the idea of digging up major streets in the CBD to lay pipework, declared unfeasible in some cases.

“But since the project was shelved they have installed a major light rail network, which was incredibly disruptive to the city,” says Snow, “so installation of major new infrastructure like a DHC would be viable given the right commercial circumstances.”

Although these projects didn’t succeed – and although cogeneration and trigeneration later fell out of favour for sustainability and economic reasons – the DHC concept remains attractive.

“Whether you have cogen in it, or hydrogen fuel cells, chillers, heat pumps, or the next flux capacitor, it doesn’t really matter,” Snow says. “It’s the energy centre and the pipework is the reticulation. That’s how you get the energy around.”

COLLECTIVE BENEFITS

As well as the floorspace that can be saved by having shared plant in another location, DHC may allow new buildings to be occupied more quickly.

“In a 20‑storey building, before you can occupy level one, you’ve got to build out all 20 floors and then install your plant on the roof and commission it and get it running so that you can condition the space below,” Snow explains.

“Now, what if you were to use a district plant that’s got pipes in the ground ready to go right there at your door when you build the basement? You build the energy‑transfer station, and then the pipe just grows with the building and you can basically occupy the building as you’re going up.

“That’s a huge benefit that just doesn’t factor into our thinking at the moment.”Snow says DHC could also help us along the road to electrification.

“Does it make sense to change every single boiler in every single building?” he says. “Or does it maybe make sense to build one new building, fit that out and then go and hook up all these new buildings?

“I think there’s a big opportunity in district systems to take on that challenge.”

TEMPERATURE CHECK

Lundberg says the Melbourne DHC event revealed the state of play for DHC systems in Australia.

What it showed was that while broad uptake may be a way off, universities are adopting the technology.

“Universities have ambitious net zero targets in Australia, and it was encouraging to see that several universities attended the event and shared their stories,” says Lundberg. “They are exploring DHC as a technology that can be implemented in brownfield campuses to provide energy‑efficient heating and cooling, reduce energy use, and integrate with the renewable technologies. Developers of greenfield campuses also talked about the opportunities of integrating DHC in their campus masterplans.

“This was a first event on this topic, and with the positive feedback, we believe that more similar events should be held in the future to capture the potential of DHC systems at universities in Australia.”

Tanks a lot

University of Queensland Gatton installed a district cooling system and thermal energy storage tank to take advantage of excess solar energy generated by its large-scale solar PV farm. The design earned McClintock Engineering Group the 2020 AIRAH Award for Excellence in Innovation.

Scan the QR code to read all about it.