A change in the air

The adoption of ISO 16890 in Australia will support better filter selection and specification, according to Daniel McCaffrey, M.AIRAH, and Peter Mathieson, F.AIRAH, from AIRAH’s IAQ Special Technical Group.

Air filtration is a critical part of our HVAC systems. To get it right, you need to know about the airborne particulate removal performance of an air filter, how the performance is determined, and what that means for your design. You need to know what air filtration outcomes to anticipate from a particular filter selection, and whether you can compare apples with apples when considering competing products.

A consistent and uniform test basis for filter classification is crucial in such instances, and this is the basis of the new air filter standard in Australia.

Finally, after some five years of work with Standards Australia, the Australian HVAC industry will align with international air filtration performance standards through the adoption of ISO16890 as AS/ISO 16890 2024.

A filtered history

Early filter classification and testing date back to 1933, when the American Society of Heating and Ventilation Engineers (ASHVE) along with the American Filter Institute (AFI) developed a standard. This primarily focused on the protection of mechanical plant and to some degree building interiors, and classified filter performance according to fine and course dusts.

The outgoing Australian standard AS 1324 originates from 1996 (revised in 2001) and was based on an earlier standard AS 1132 from 1972, as well as the 1993 version of EN 779 and the 1992 version of ASHRAE 52. This looked at average efficiency (number 1 test dust), and average arrestance (ASHRAE test dust 4), intended to evaluate the likely service life of an air filter.

Unfortunately, the efficiency method was based on a 1957 method, developed for determining respirator filter performance and, in practice, test dust 1 demonstrated a tolerance margin, on penetration, of ±15%. So reported 20% efficiency filters, may have had an observed efficiency ranging anywhere between 8% and 32%. This was not a reliable basis for a reduction in AS1668.2 outdoor air rates.

It is important to realise that filter classifications are never meant to replicate the actual performance of filters in field applications; they are simply a method for comparing products assessed to a uniform and reproduceable laboratory test intended to simulate, not replicate, real-world conditions. Advances in instrumentation and particle science have led to tremendous improvements determining comparative air filter performance, in a more accurate, reliable, and reproducible way.

The European standard EN 779 has had two updates since the earlier Australian Standard was published. The most recent was in 2012, and introduced a change from average efficiency to minimum efficiency, before and after any electrostatic performance enhancements were removed from the filter media.

In 1999, ASHRAE standard 52.2 was introduced and adopted Minimum Efficiency Reporting Value (MERV) for particulate matter (PM) ranging from 0.3 to 10µm.

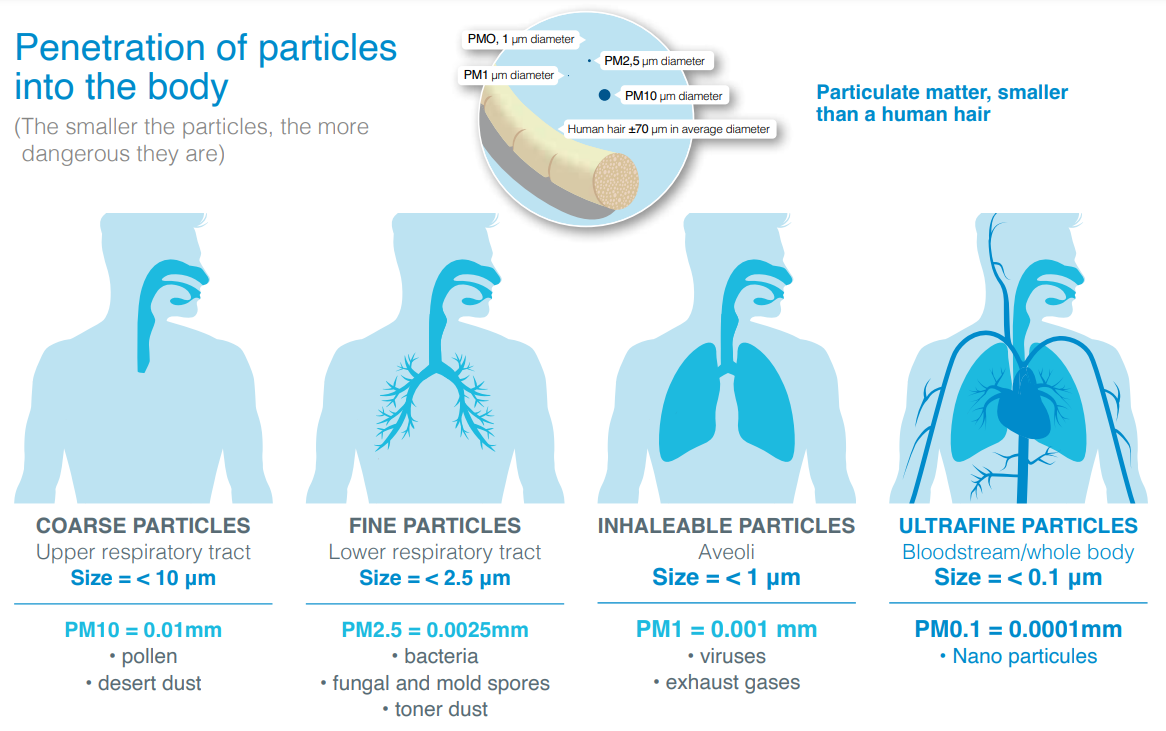

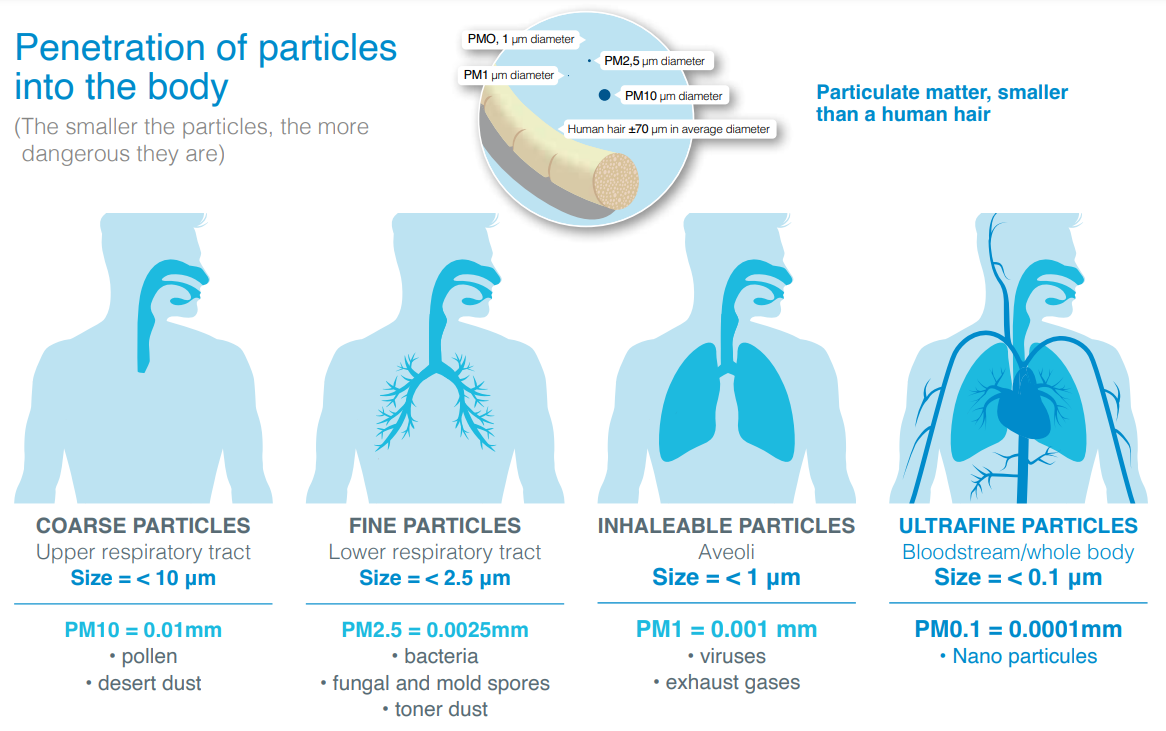

The change from average to minimum efficiency makes sense, because filters are generally at their lowest performance when clean. It is also an important recognition of the deleterious impact of fine and ultra fine particulates on respiratory health (including the transmission of viruses). The latest standard allows the health impacts of particulates, as shown in Figure 1, to be assessed for the application.

A class apart

One of the most noticeable changes under AS/ISO 16890 is the shift from filter ratings such as G4 or F8 to ratings that more accurately indicate performance for different sizes of particles.

For example, ASHRAE 52.2 MERV 13 filtration targets a 50% reduction in PM1 particles (viruses) when the filter is clean. AS/ISO 16890 represents this performance classification as ePM1 > 50% and considers it a Fine filter classification. Gone is the generic classification label of F7 previously familiar for such a filter. The AS/ISO16890 classification immediately identifies minimum filter performance for a specific particle size.

Typical Fine classifications include, ePM1 >80%, ePM1 >70%, and ePM1 >50%. These would formerly be classified as F9, F8 and F7 respectively in the now withdrawn EN 779.2012.

Filters that capture <50% of PM10 size are classified as coarse and the arrestance is measured against the first cycle of loading with ISO 12103 A2 synthetic dust. As a general reference, ePM10 >50% may previously have been classified >F5. Coarse filters cover filters previously classified G1 to G4, and are now classified by removal efficiency on first cycle loading in 5% increments to 95%.

The new standard provides the Australian market with performance classifications that are consistent with requirements applied in Europe. This will give Australian specifiers greater certainty in selecting filtration products to best suit the intended application.

Energy efficiency

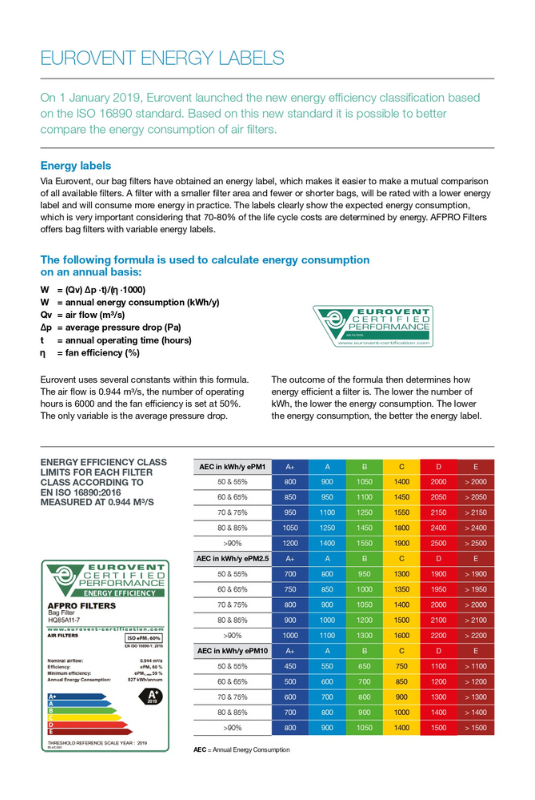

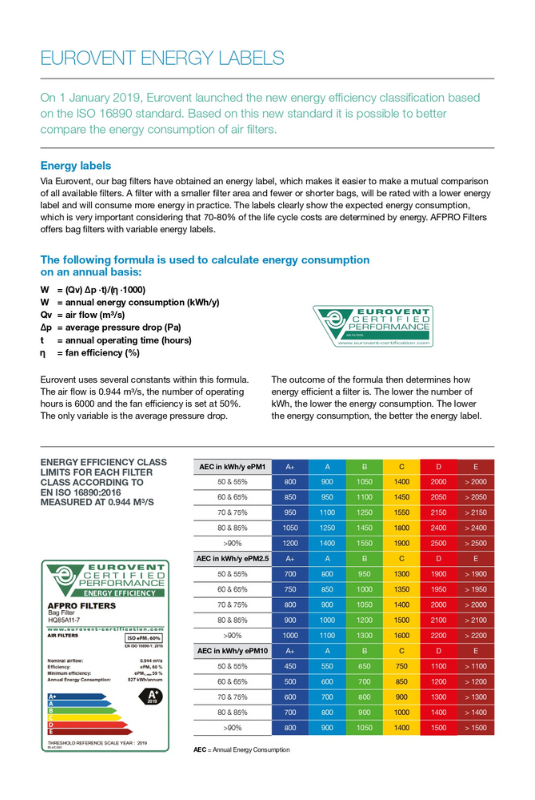

Manufacturers develop filter designs and material selections with the goal of maximum particulate removal efficiency with minimum fan energy (airflow pressure loss). The Eurovent certification system ranks filters by both ePMxx performance and life-cycle fan energy consumption using the calculation in Figure 2. This is expressed in kWh/y then scaled from A+ down to E as shown in Table 3.

Selecting filter products with a higher rating (but the same ePMxx performance) can significantly reduce HVAC energy use – and associated CO2 emissions.

Of course, any life-cycle comparison should include the costs of changing out filters (in labour and material costs) as well as associated energy use. This should also be considered when determining the optimal duty cycles.

Switching to the new standard

The transition to AS/ISO 16890 will occur over a two-year period from mid-2024.

The new AS/ISO16890 is referenced in the revised AS1668.2 standard, marking a significant shift in our approach. It mandates the use of the AS/ISO 16890 test method as the basis of air filter selection for designs that seek a reduction in outside air ventilation. Either for the deemed-to-satisfy (ISO ePM2.5 >50% for a 25% reduction), or for the performance approach (to establish the filter fractional efficiency for use in the calculation for reducing the outside air).

It is important to familiarise yourself with filter products rated to ISO/AS 16890 and the new classification approach, and seize the potential offered to deliver improved performance outcomes.

Breaking it down

AS/ISO 16890 comes as Parts 1 to 4.

Part 1 is an overview and details the technical specifications, requirements and performance classifications based on filter particulate matter removal efficiency. To maintain uniformity and reproducibility of results, regardless of the lab location, the test is carried out in a controlled environment of 23°C ±5°C and 45RH ±10% RH.

Part 2 describes the method of determining a filter’s performance to PM1, PM2.5 and PM10. Upstream and downstream dust concentrations are measured by particle size, broken up by 12 size channel segments, to arrive at the three size segments that are reportable. It classifies filters into three classes of removal efficiency by particle size, each with 10 performance increments of 5%, for minimum performance >50% of particle size removed, averaged between before and after electrostatic discharge for PM1 and PM2.5 rounded down to the nearest 5%. This means an observed 68% to PM1 and 72% to PM2.5 pre-discharge and 49% to PM1 and 68% to PM2.5 post-discharge is classed as an ePM2.5 70% filter, being the average between pre- and post-discharge. Performance needs to be over 50% in both states to be classified in that particle size segment.

As mentioned above, filters are tested pre- and post-electrostatic discharge. Also, the size segments are inclusive of 0.3µm to 1µm, 2.5µm and 10µm for ePM1, ePM2.5 and ePM10. Finally, an urban particle size is applied to weight distribution for PM1 and PM2.5, and a rural particle size to weight distribution for PM10 to enable the reporting of filtration performance as a removal percentage in units of micrograms per cubic metre (µg/m³), which is directly relatable to the challenge of outdoor air quality (OAQ) and indoor air quality (IAQ) accessible from monitoring services and devices.

Part 3 describes the method to determine filter arrestance to synthetic dust load and resistance to airflow. The synthetic dust used for this task is ISO 12103 A2 dust as used in AS 1324 or ASHRAE test dust 4, without the 5% cotton or 23% carbon content. This is 2.5 times heavier than the ASHRAE test dust, making it is easier to trace conformity of the test dust as well as providing a more challenging method to determine filter performance, particularly a filter’s ability to hold high dust loads without shedding. AS/ISO 16890 classifies Coarse filters by the dust removed in the initial dust loading cycle. Dust holding capacity can be determined after loading to 300Pa for ePMxx filters and 200Pa for Coarse filters.

Although manufacturers can report dust holding capacity and average arrestance, these do not determine the a filter’s classification. Loading can continue to a higher final resistance if sought by the manufacturer or end-user, but it is not required by the standard. This may be important if filters are used in critical applications where the burst pressure needs to be determined.

Part 4 describes the method to remove any electrostatic enhancement of the filter media. The filter is placed in a cabinet and exposed to saturated IPA vapour/air mixture at 25°C ± 5°C for 24 hours. This simulates, in a short time, the performance deterioration found in service, particularly when air filters are exposed to outside air with occasionally high concentrations of fine PM that can occur within the first 5% of the filter’s expected service life.

The Australian version of ISO 16890 has an added appendix so that results from tests conducted in Australia are reproduceable in any test laboratory and vice versa. The test facility must have qualified independent third-party accreditation to confirm the technical competency in producing valid and reliable results. It also covers marking ID on the filter and the dates of any published performance data.

Further guidance

For more information on filters and selecting the right filter for HVAC systems, refer to AIRAH’s DA15 manual. Members can access this resource online via airah.org.au/site/resources/da-manuals

This article appears in Ecolibrium’s August-September 2024 edition

View the archive of previous editions

Latest edition

See everything from the latest edition of Ecolibrium, AIRAH’s official journal.