As part of the ACT’s government’s drive to net zero by 2045, it has effectively decarbonised the territory’s electricity supply – a bold move in a cold capital. Its newest office at 480 Northbourne Avenue in Dickson is predicated on an all-electric design. By Dr Paul Bannister, F.AIRAH.

By Dr. Paul Bannister

The use of gas for heating in Australian commercial buildings is very much the norm, and particularly so in the cooler climates where the heating loads are larger. This has been driven by the lower cost of gas, its ability to avoid high peak-demand charges, and the compact nature of gas plant relative to capacity. However, as the Australian electricity grid decarbonises, the greenhouse gas implications of gas use are becoming more problematic – (See breakout “Going, going…”) – and the pressure for buildings to go all electric builds.

In Canberra, the ACT government has taken a strong environmental leadership position as part of its drive to net zero by 2045. In so doing, the government have effectively decarbonised the entire territory’s electricity supply through its long-term contracts for the purchase of renewable energy. The initiative is part of the government’s drive to net zero by 2045.

It is little surprise, then, that the ACT government briefed the developer to pursue an all-electric solution for its newest office at 480 Northbourne Avenue in Dickson. However, in Australia’s coldest capital city, the step to all-electric is not one to be taken lightly.

The building was sited close to public transport as part of the ACT government’s “hub and satellite” strategy. Photo: Peter Clarke.

The building

Developed by Doma, 480 Northbourne Ave is the new ACT government building in Dickson in inner north Canberra, with a floor area of 13,267m2 NLA across six floors. The project is aiming for a 5 star NABERS ratings for energy efficiency, water usage, waste management and indoor air quality.

Recently awarded the John Andrews Award for Commercial Architecture by the ACT Chapter of the Australian Institute of Architects, the building was designed by Bates Smart Architects. One of the key design features is a stunning central atrium with an elegant spiral staircase, designed to enhance both daylight and interaction within the building.

The ground floor houses reception, the Access Canberra shopfront, several meeting rooms for interaction with the public, and a café. The upper floors consistent of two office floor plates flanking the atrium space and serviced by highly visible glass lifts travelling through the atrium.

When the building was tendered, it was proposed as a conventional building served with a gas heating system. However, the ACT government quickly realised that this would lock in emissions beyond its net zero target, and proceeded to negotiate with developer/owner DOMA the revision of the design to all-electric.

DOMA has rented the building to the government on a 20-year lease.

“We always planned for this building to be a long-term investment,” says Doma senior development manager David Jameson. “So, we wanted to be sure that changing to all-electric would not devalue the building or have long-term whole-of-life implications. We went through a significant internal process to evaluate the impacts. We were particularly concerned about the possibility that it would impact on the ability of the building to achieve its 5 Star NABERS target, given that this is a contractual target with rent-abatement provisions.

Going, going …

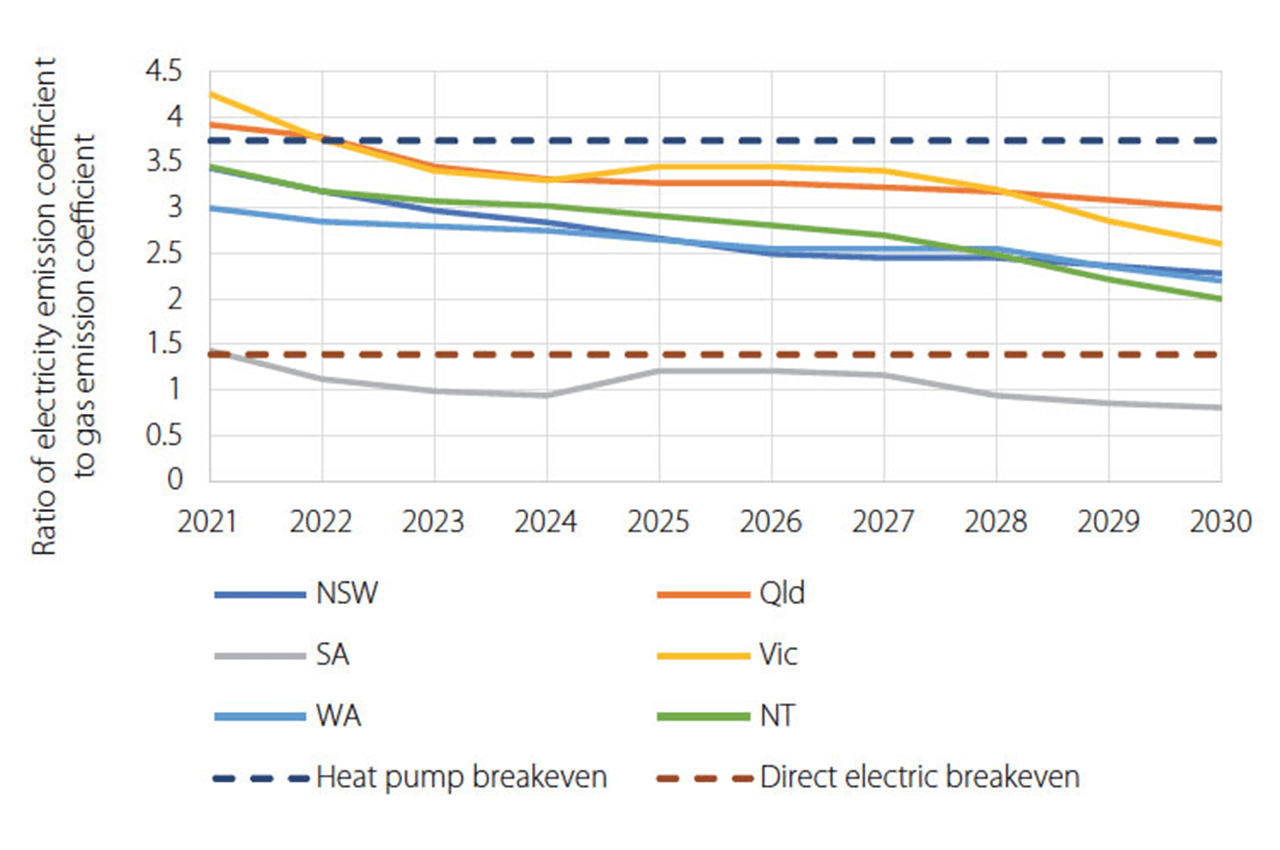

Very roughly speaking, if we compare a gas system operating at 85 per cent annual efficiency with a heat pump system working at a COP of 3, then electricity becomes a lower emissions solution when the electricity greenhouse gas coefficient is less than 3.5 times the gas greenhouse gas coefficient. As can be seen in the figure below, this is already the case in many states, and will be true nationally by 2025. It can also be seen that in SA, direct electric is more than competitive with gas on a greenhouse basis; it will take more than a decade for other mainland states to catch up with this, though.

“We also had to satisfy ourselves that we were covered for the performance of the system, particularly early-winter warm-up, achievement of the lease temperature-control requirements, capital cost and outgoings, availability of equipment spares, building value for the life of the asset and reputational risks. Our analyses showed that it all stacked up.

“Furthermore, a lot of our development pipeline targets Commonwealth tenants, so developing this experience with all-electric buildings in Canberra has long-term value to us. There was an additional capital cost. The ACT government was wanting to lead by example and were able to contribute to these changes project through the ACT government’s Zero Emissions Government Program.

The mechanical services were designed by ACOR/Rudd Consulting’s Melbourne office. Project engineer Ryan Tanner outlines the building design as follows:

“The main HVAC plant comprises of one off 315 kW water cooled chiller and three off 532kW air-cooled heat pump scroll chillers in a parallel arrangement to provide heating and cooling for the building.

“During cooling mode, the water-cooled chiller operates first to maximise the efficiency during part-load conditions, with the heat pump chillers taking care of the remainder of building cooling load.

The atrium and its spiral stair forms a natural location for circulation both vertically and horizontally.

Photo: Peter Clarke.

“In heating mode, the heat pump chillers operate to take care of the building heating load. This plant configuration also gives the flexibility to provide heating and cooling to the building simultaneously. The CHW and HHW loops are set up in a primary/secondary pumping configuration, as the heat pump chillers tend to operate more stably with a constant water flow, whilst being able to vary the pump speed and water flow on the field loop. Two off induced-draft counter-flow cooling towers provide condenser water for the water-cooled chiller and tenant supplementary cooling loop.

“From an airside perspective, there are eight air handlers, which have been zoned and broken up to serve each perimeter zone and the internal zone, so as to avoid the need for reheat coils. Low-temperature variable air volume (VAV) systems have been adopted for the building to help minimise fan energy in conjunction with EC plug fans.

“The main air handling units incorporate rotary wheel heat exchangers to reclaim heat/coolth and pre-treat outside air entering the system. All air handling plant also incorporates economy cycle mode of operation, night purge operation and CO2 monitoring to modulate outside air volumes.

“The key with the all-electric solution was to get the water side right in terms of water flows, water temperatures and coil sizing. From an airside perspective, the air is still supplied to the space at the same temperature, whether it is a gas boiler solution or an all-electric solution. The façade requirements were driven from the perspective of reducing energy usage in the building and achieving a high NABERS rating; no additional façade measures were included on account of the all-electric solution.

“To complement the all-electric heating and cooling solution, a 136kW PV array was installed on the roof, which offsets a large portion of the chiller energy.”

One of the challenges was finding space for the chillers on the roof, and ensuring they did not create noise issues with neighbours.

Photo: Peter Clarke.

challenges

It goes without saying that there were challenges along the way. In the first instance, eight different design options were considered. From a technical perspective, Tanner says Canberra’s renowned frigid temperatures provided a considerable challenge.

“The main challenge with going all electric is Canberra’s cold climate,” Tanner says. “During cold ambient temperatures the electric heat pump chillers tend to drop off in heating capacity and efficiency, and will periodically go into defrost mode to prevent the coils freezing, effectively losing a portion of heating capacity for periods of time.

“All these and many other factors needed to be factored in when determining the optimum plant arrangement, to ensure a sufficient level of redundancy in the system and to ensure satisfactory temperatures are maintained within the office tenancy.

“As heat pump chillers of this scale are only capable of producing up to 55°C water temperatures – and this water temperatures drops as the ambient temperatures drops below 0°C – it was imperative that the coils within the air handling plant were sufficiently sized and selected to deal with the required heating load.

“Typically, a gas boiler can provide 80°C water temperature at any ambient temperature. Air-to-air heat exchangers were adopted in the air handling plant to help reduce heating loads associated with the outside air, particularly during winter. This assisted with the coil sizing.”

Tanner says another challenge was physically fitting all the chiller plant on the roof, while finding an appropriate location from an acoustic perspective.

“Electric heat pump chillers take up a much larger footprint than boiler plant,” he says. “And unlike boiler plant, typically need to be located outside rather than in a plantroom. The other three neighbouring buildings on the Dickson site all have multiple levels of residential apartments, some of which are directly opposite the office building. A detailed acoustic assessment needed to be undertaken to ensure the noise generated by the chillers was at an acceptable level at the neighbouring properties.”

For all the challenges, compromise of the building’s environmental credentials was not something that was permitted. The building has achieved a 5 Star Green Star Design and As Built v1.1 rating, and has a design-reviewed NABERS Commitment agreement for 5 Stars. The project is also an entrant to the Property Council of Australia’s Innovation and Excellence awards under the innovation category.

The building is already heading into its second Canberra winter and has performed well against the associated challenges. Performance is tracking in the region of 5.5 stars NABERS, significantly ahead of the official target.

Occupant perspective

Of course, all the environmental credentials in the world count for nothing if the building is uncomfortable or difficult to use. Craig Simmons, chair of the 480 Northbourne Avenue executive committee, is firm on the benefits that the building has delivered.

“The ACT government is adapting the way we work to better meet the needs of a modern workforce,” he says. “480 NBA was designed from the start to be an activity-based workplace (ABW) and is the first purposed designed ABW for the ACT government.

“While the COVID-19 health emergency has limited the ability to fully occupy and use the building to it maximum capacity, the design has been very well received by staff. The open nature of the building and the atrium, which floods the building with light and due to its glass roof connects everyone in the building with what’s going on in the world outside. The openness of the building, the quality of the light and the build are the most commented on by people working or visiting the building.

“480 NBA has enhanced our work experience and transition to an activity-based working environment, which includes dedicated neighbourhoods, breakout spaces, quiet spaces and meeting rooms.”

“It is my strong belief that this is not only the best office building that the ACT government occupies but is also the best office building in the ACT, and clearly demonstrates that high- quality, high-efficiency, low-emissions buildings are achievable.”

net zero hero

The ACT’s emissions reduction targets are some of the most ambitious in the country. It aims to reach net zero by 2045, with interim targets along the way. In 2020, the ACT met the target of 100 per cent renewable electricity supply. This transition enabled the ACT to achieve its first emissions reduction target of 40 per cent by 2020. For more information go to www.environment.act.gov.au

Lessons for the next building

Every project comes with lessons learnt and opportunities missed. Tanner says that if he could start again, he would look at repositioning the core locations to reduce duct runs, and push to have a larger outdoor plant area to improve clearance and airflow around the chillers.

Furthermore, when the plant was ordered, there were no low-GWP heat pump chillers available, and as a result the equipment in the building uses R410a. However, with low-GWP alternatives available as of 2020, Tanner says that had the project been constructed a year later, the team would have opted to select chillers with an HFO refrigerant.

Tanner is enthusiastic about future all-electric projects for cold climates.

The building has achieved a 5 Star Green Star Design and As Built v1.1 rating, and has a design‑reviewed NABERS Commitment agreement for 5 Stars.

Photo: Peter Clarke.

“ACOR Rudds Consultants have for a number of years now been an advocate of all-electric solutions, and in most instances is the default path we head down when determining an appropriate heating/cooling solution for a building,” he says.

“We have recognised that the industry is heading that way, and with many councils now committing to net zero emissions by 2040, it is inevitable that gas plant will be phased out in buildings. There are a number of energy-efficient electric options available on the market – VRF/VRF, air to water heat pumps, water-to-water heat pumps to name a few – which are a good alternative to using gas plant. As long as you understand the limitations and intricacies of the plant, especially in colder climates, then you should not have any issues.”

Curved balconies create a layered effect that draws the eye to the light from above, and create places for occupants to rest and meet.

Photo: Peter Clarke.

Similarly, Doma’s Jameson is keen to repeat the experience: “We do a lot of Commonwealth Government tenders, and we are looking to bring the all-electric approach into future projects. We have proven that it can work within the Canberra environment and believe it’s the way of the future. We believe that in the coming years an all-electric building will become mandatory in client briefs.”

With 480 Northbourne Avenue proving that you can build a highly efficient all-electric in Australia’s coldest capital city, paving the way towards net zero, there are no excuses left for locking fossil fuel use into new office buildings in Australia.

Stepping up to the challenge– 480 Northbourne Avenue shows what is possible in the push towards net zero. Photo: Peter Clarke.